Guide roller of vertical aluminum foil slitter and production method thereof

A production method and technology of slitting machine, which are applied in the directions of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems such as the inability to reach the strip line speed, the slow increase in the rotational speed of the guide rollers, and the inability to increase the production speed, etc. To achieve the effect of easy assurance of processing quality, improved production efficiency and excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The present invention aims at a series of problems caused by the heavy weight of the guide roller of the existing aluminum foil vertical slitting machine due to the use of solid steel material, and proposes a guide roller with a new material roller body, which not only greatly reduces the weight, but also The strength is also greatly enhanced, thus solving a series of problems such as scratching the strip due to the heavy weight.

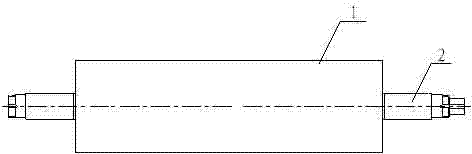

[0038] refer to figure 1 As shown, the existing aluminum foil vertical slitting machine guide roller includes a roller body 1 and a shaft head 2. The roller body 1 is made of steel material and is a solid structure with a large weight. The shaft head 2 is embedded in the roller body 1. The length is shorter, only 50mm.

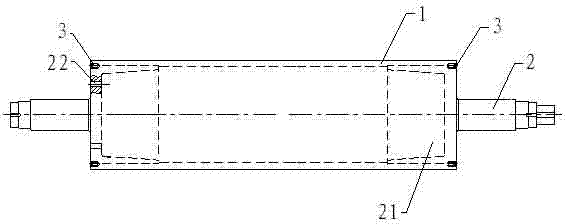

[0039] refer to Figure 2-Figure 4 As shown, the aluminum foil vertical slitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com