Waveform monitor apparatus of injection molding machine

A technology of injection molding machine and monitoring device, which is applied in the field of waveform monitoring device, can solve problems such as not necessarily sufficient, achieve molding quality and pass rate, and contribute to the effect of versatility and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

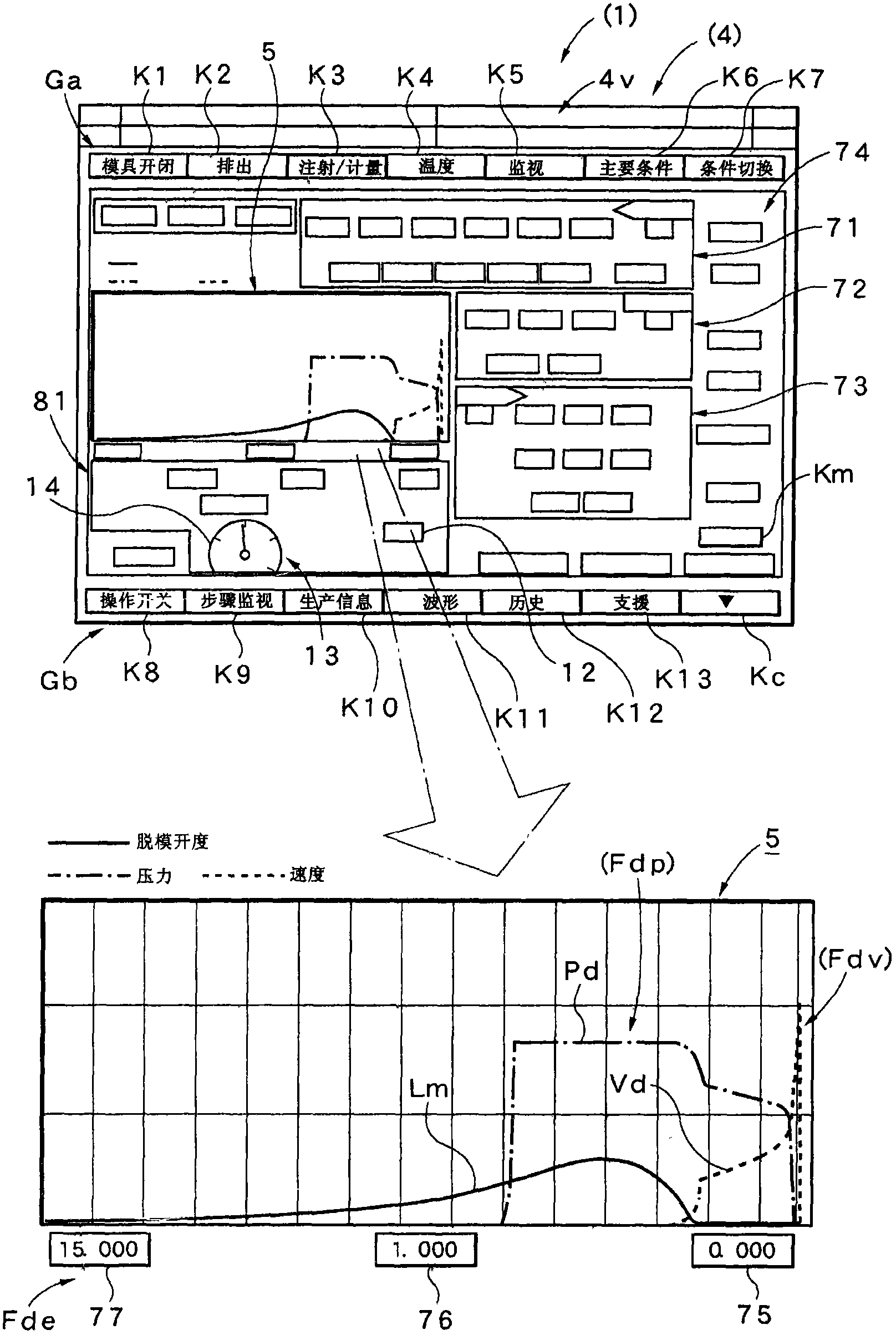

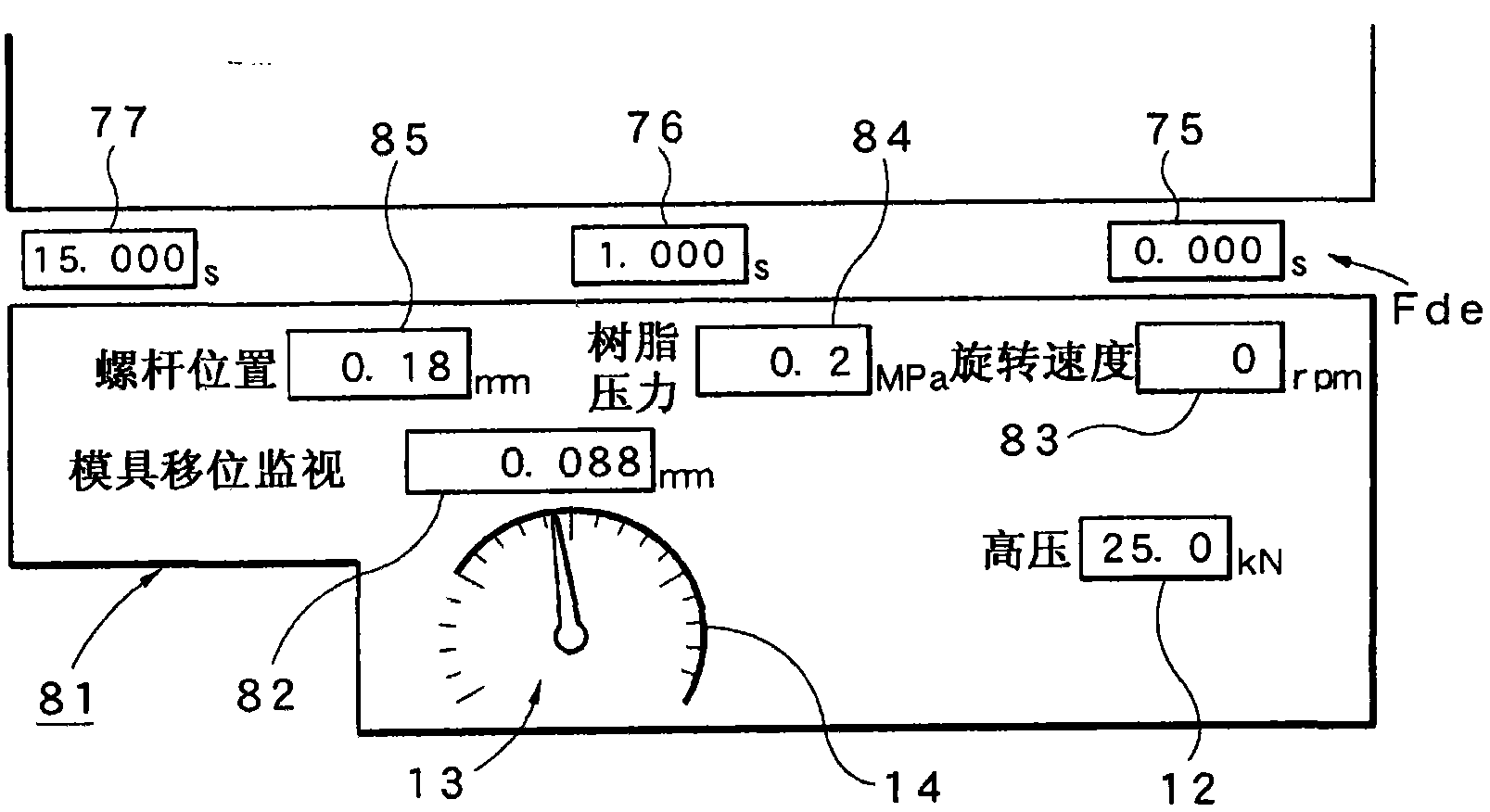

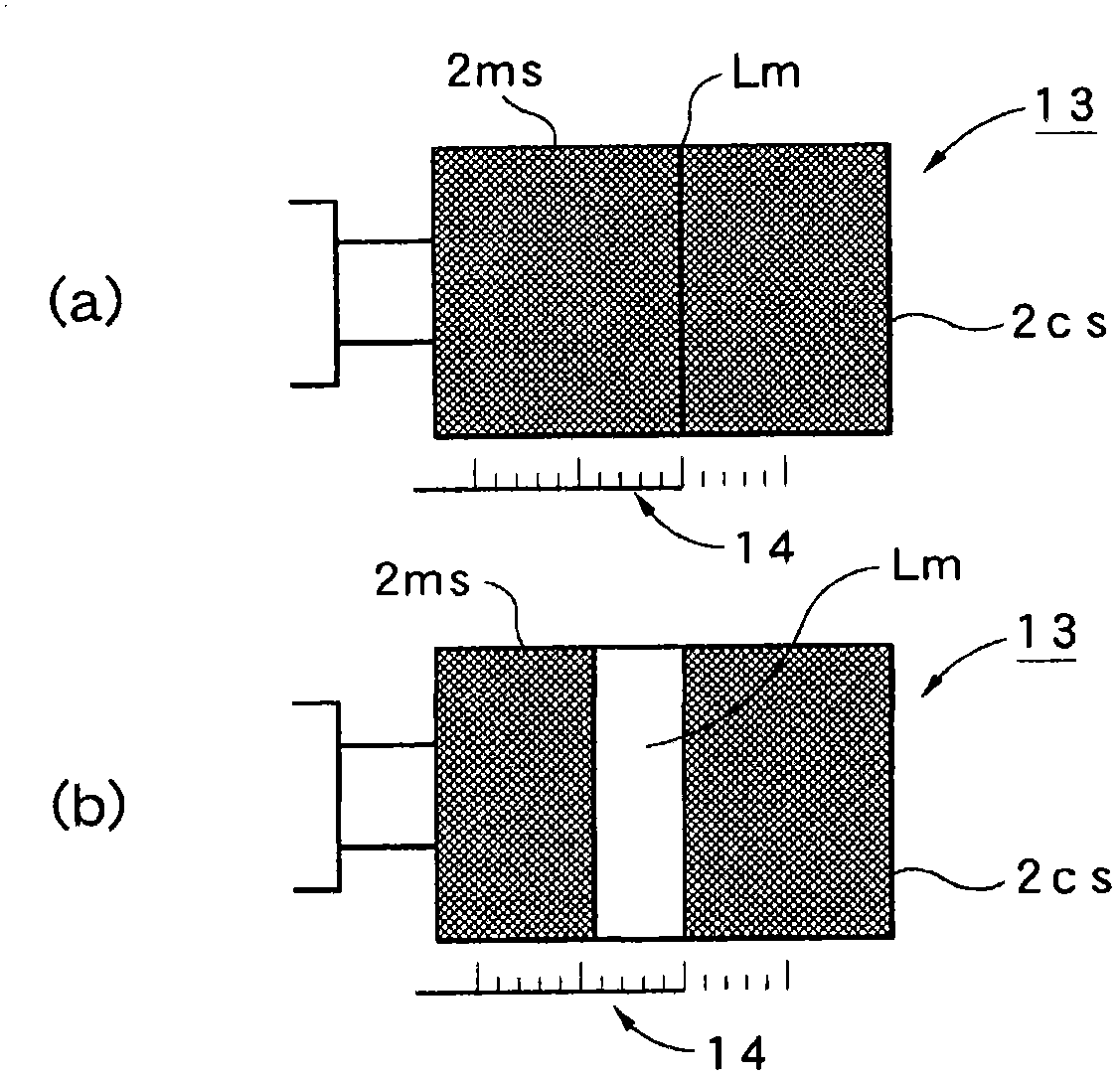

[0037] Preferred embodiments of the present invention will be listed below, and will be specifically described with reference to the accompanying drawings. The accompanying drawings do not limit the present invention, but are for easy understanding of the present invention. In addition, with regard to known parts, in order to avoid ambiguity of the present invention, specific descriptions are omitted.

[0038] Below, refer to Figure 1 to Figure 5 , the configuration of the injection molding machine M equipped with the waveform monitoring device 1 of the present embodiment will be described.

[0039] exist Figure 4 Among them, symbol M is an injection molding machine, and the injection molding machine includes an injection device Mi and a mold clamping device Mc. The injection device Mi includes a heating cylinder 21 having an injection nozzle 21n at the front end and a stocker 21h at the rear, and a screw 22 is inserted inside the heating cylinder 21, and a screw driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com