Image detection control method for sheet material defects

A technology of image detection and control method, applied in the direction of optical testing flaws/defects, etc., can solve the problems of unreal detection information and inability to provide suggestions for sheet processing plans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

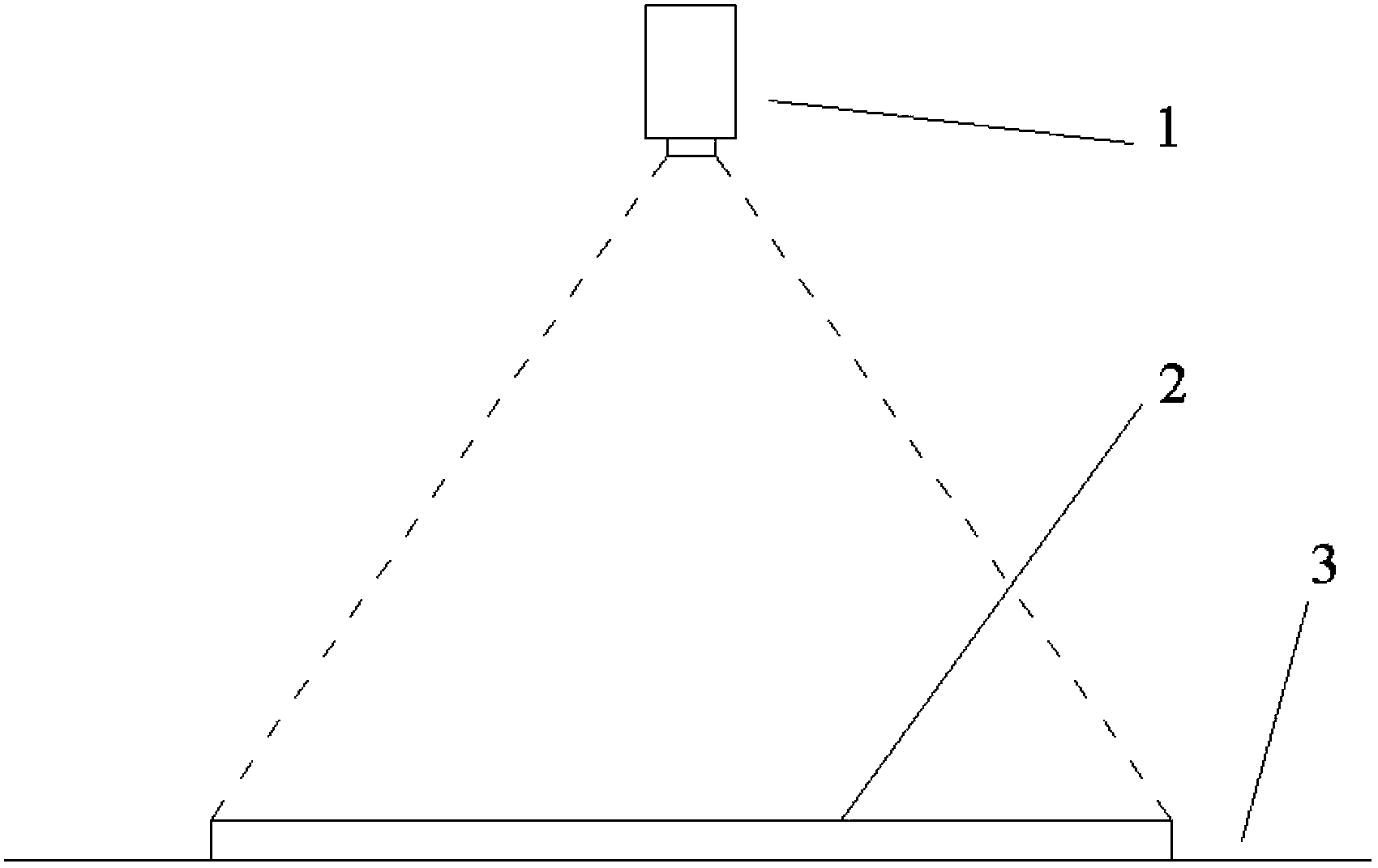

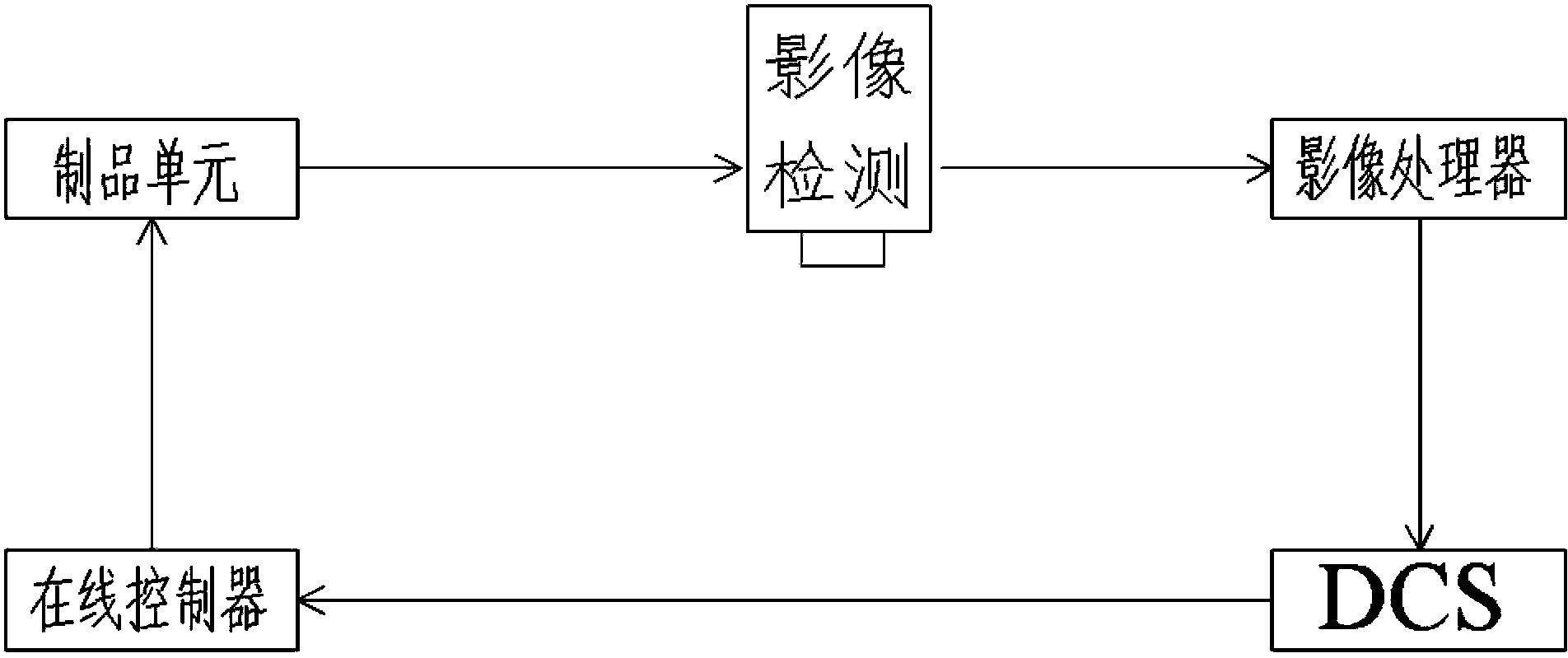

[0020] see figure 1 , which shows the layout of the high-speed image inspection equipment in the production system of the online image inspection control system for plate defects according to the present invention. Among them, the plate product unit 2 is formed on the forming table 3, and a high-speed image detection device 1 is arranged above the plate product unit 2 for online acquisition of dynamic image information of the plate product unit passing below it. The high-speed image inspection device 1 can use a surface scanning image inspection system or a line scanning ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com