Multiuse oil gas energy-saving stove

An energy-saving stove and multi-purpose technology, which is applied in the field of oil and gas stoves, can solve the problems of energy waste of ordinary stoves, and achieve the effect of clean and beautiful kitchen, simple production process and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

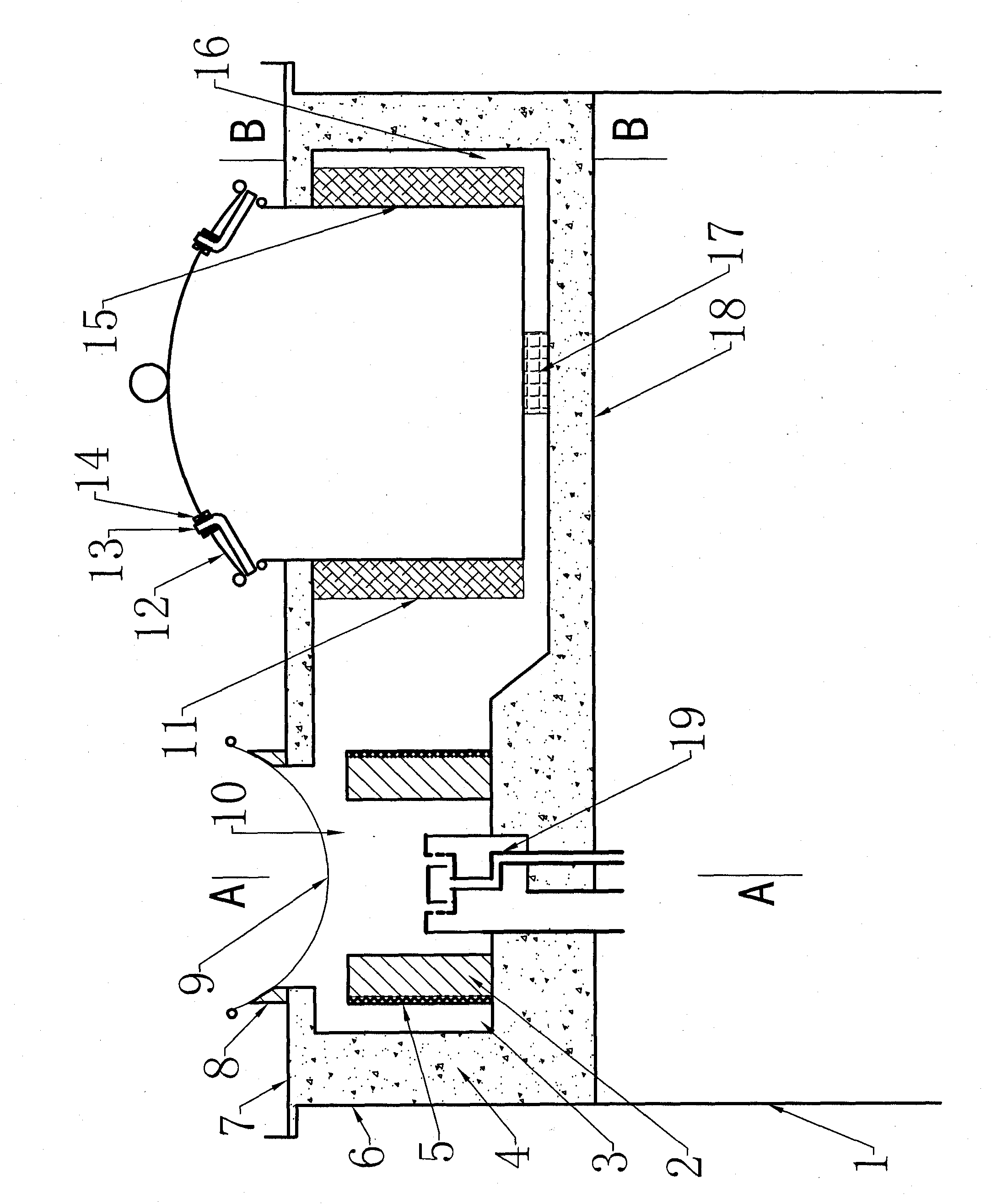

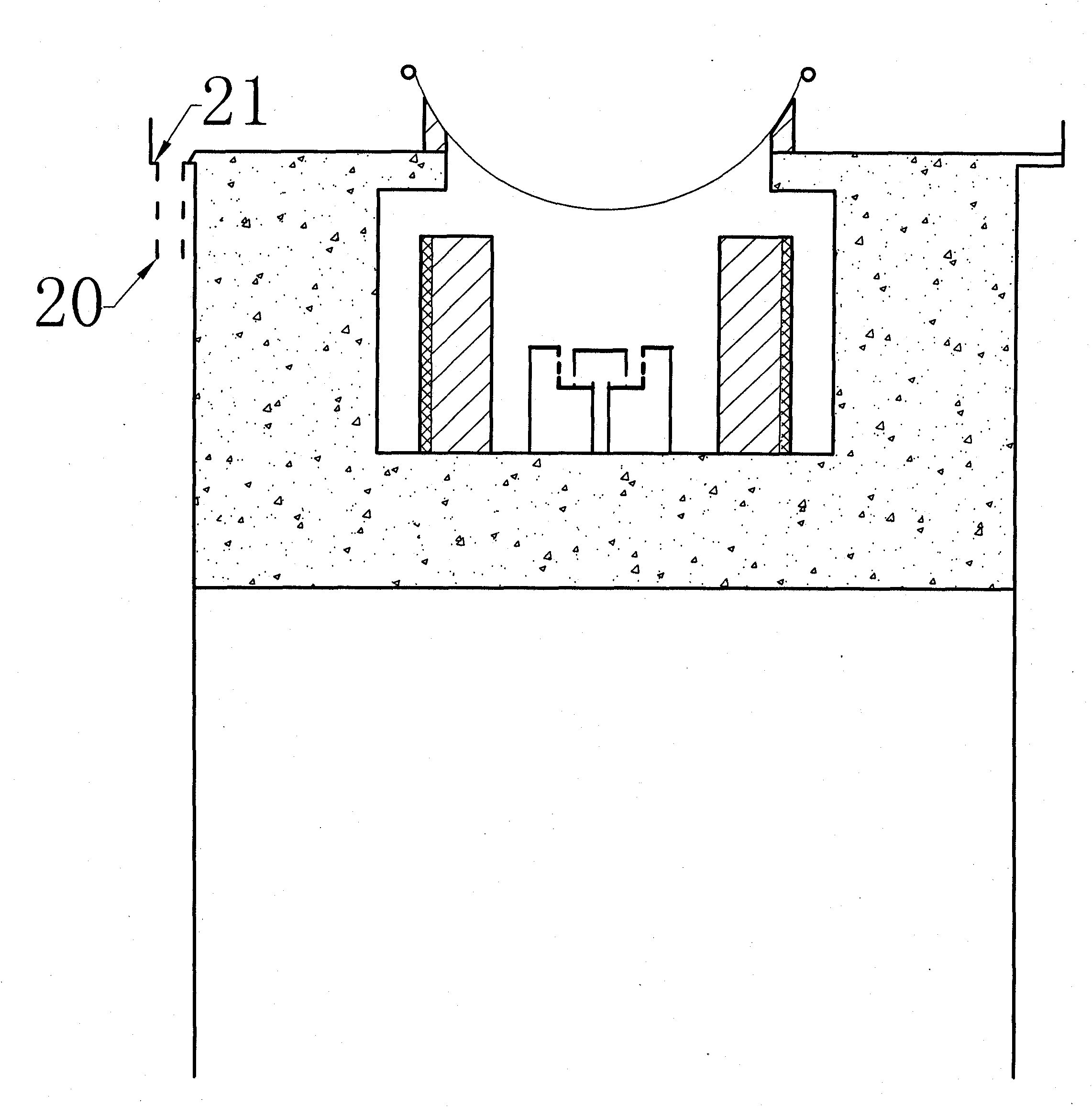

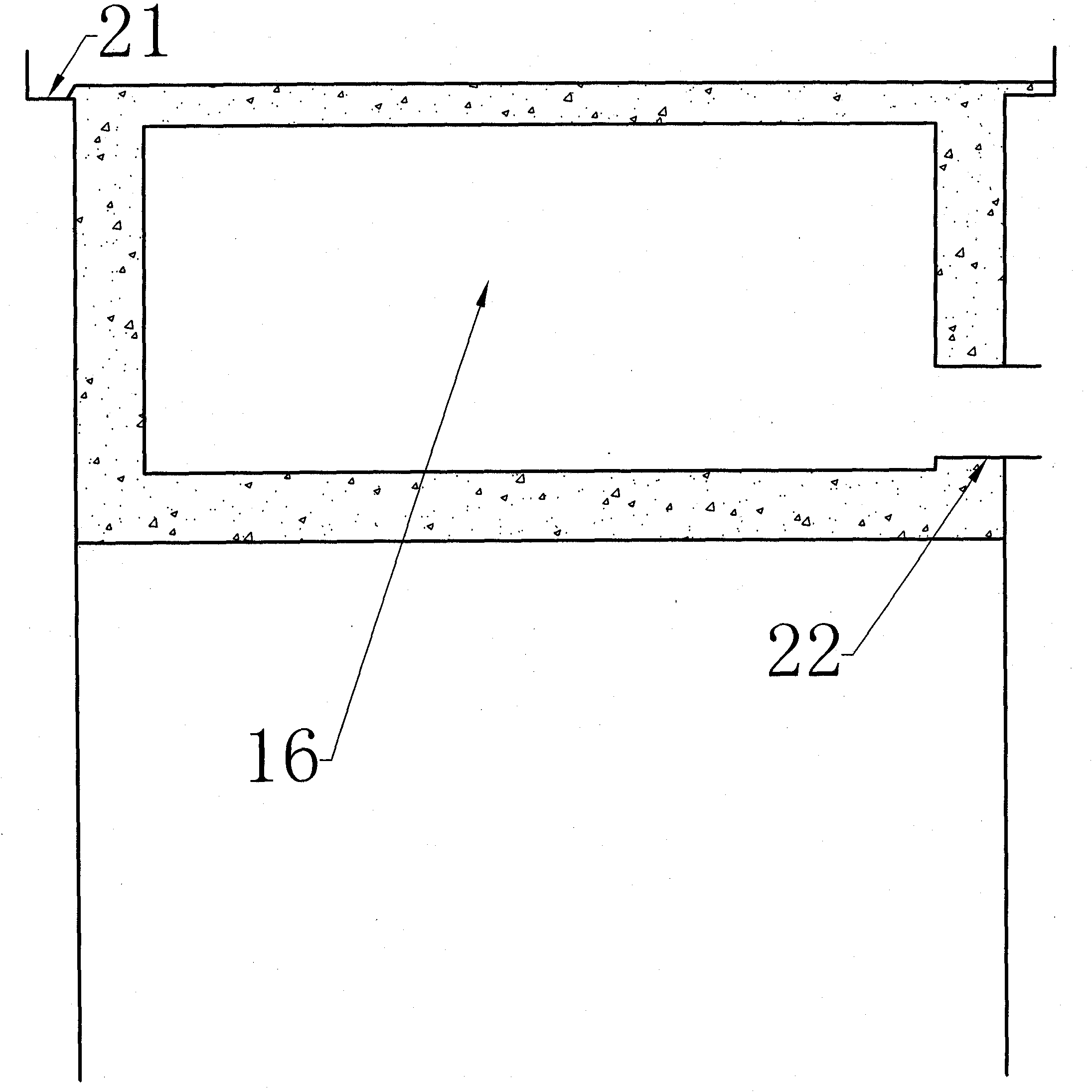

[0018] The attached drawings describe the structure of a multi-purpose oil and gas energy-saving stove. The leg 1 and the shell 6 are fixed together; the shell and the bottom plate 18 are fixed together; the refractory layer 2 and the outer reinforcement layer 5 together form a refractory core, and the reinforcement layer 5 is a steel mesh refractory structure; there is an insulation layer 5 inside the shell; The inside is a cavity. The refractory core and water tank 15 are installed in the cavity with a gap between the insulation layer and the water tank. There are multiple fins 11 outside the water tank. The fins and the water tank are integrally cast or die-cast, or the fins and the water tank are welded together. Or the fins and the water tank are integrally extruded and then welded to the bottom of the water tank; the support 17 on the outer periphery of the water tank fixes the water tank in the cavity; the water tank cover 12 is installed and fixed with multiple isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com