Double-steel-wheeled vibratory road roller with hydraulic pipe fastening device

A technology of vibratory rollers and double steel wheels, which is applied in the field of construction machinery, can solve the problems that the double steel wheel vibratory rollers cannot operate normally and troublesome work, and achieve the effect of solving frequent wear and tear, ensuring safety and protecting normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in combination with specific embodiments and accompanying drawings.

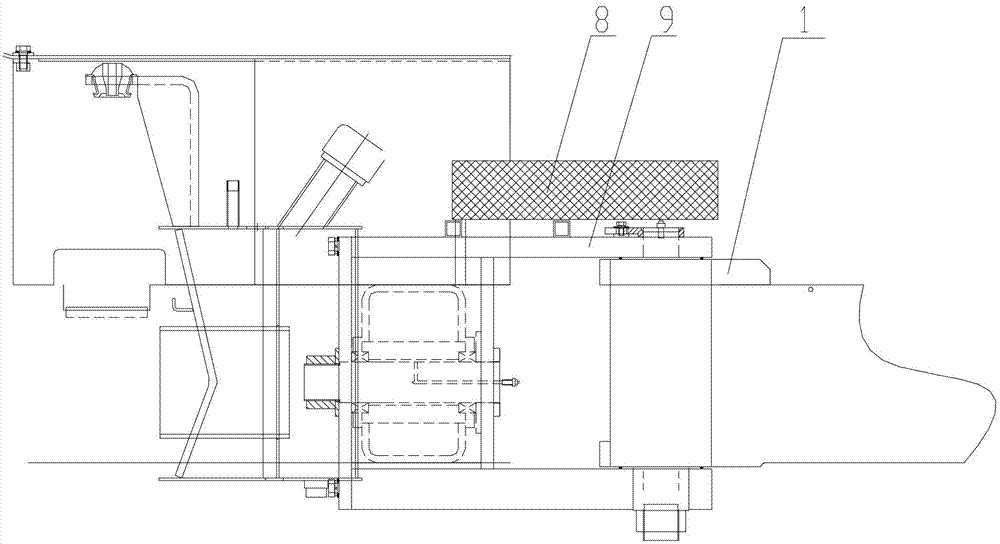

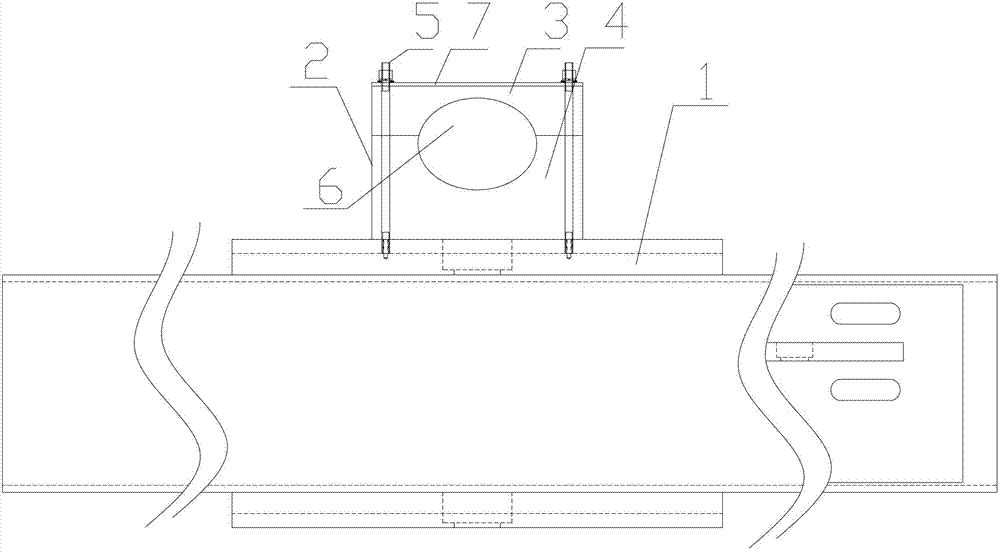

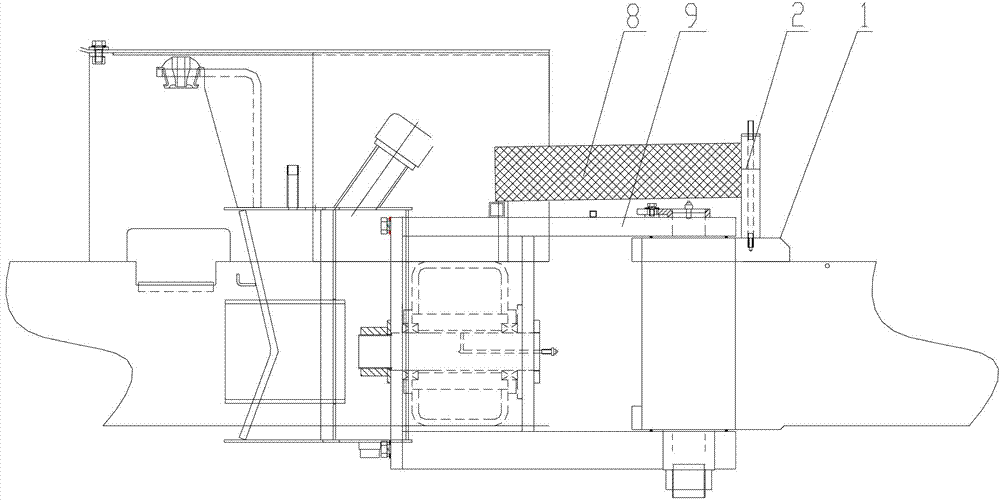

[0014] Such as Figure 2 to Figure 3 The shown double-steel-wheel vibratory roller with a hydraulic pipe fastening device includes a rear frame 1, and two threaded holes are opened on the rear frame 1, and a double-drum roller is screwed in each threaded hole. A head bolt 5, a hydraulic pipe fastening device 2 mainly composed of a first rubber plate 3 and a second rubber plate 4 is arranged on the rear frame 1, and the first rubber plate 3 and the second rubber plate 4 Longitudinal through-holes used in conjunction with stud bolts 5 are respectively arranged on the top, the first rubber plate 3 and the second rubber plate 4 are combined up and down and screwed on the rear frame 1 by two stud bolts 5, The ends of the first rubber plate 3 and the second rubber plate 4 are respectively provided with a half mounting hole for clamping the hydraulic pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com