Pressure-assisted weaving and dyeing compression roller capable of preventing pressure non-uniformity of middle edges

A pressure and pressure roller technology, applied in the field of textile and printing, dyeing and finishing machinery, can solve the problems of pressure roller difficulty, difficulty in accurately calculating pressure uniformity, etc., to achieve uniform pressure and solve the effect of color difference in the middle and edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

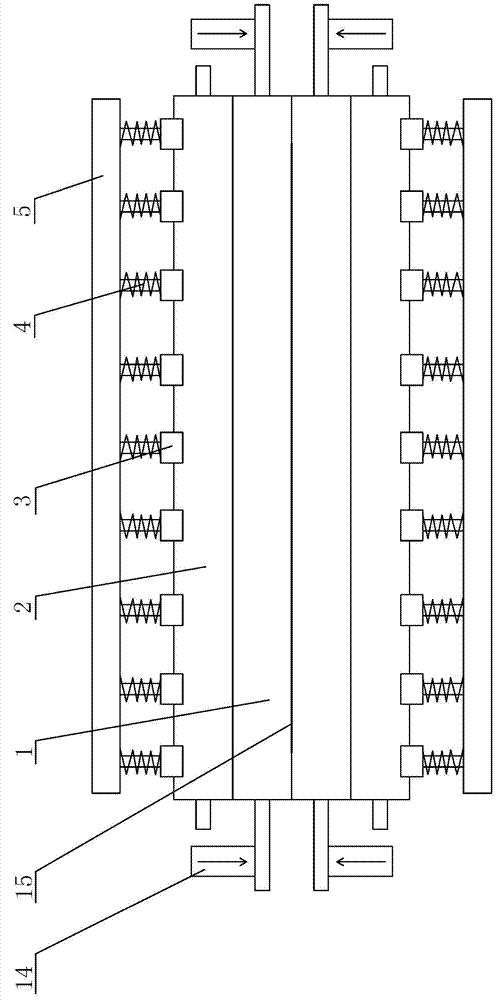

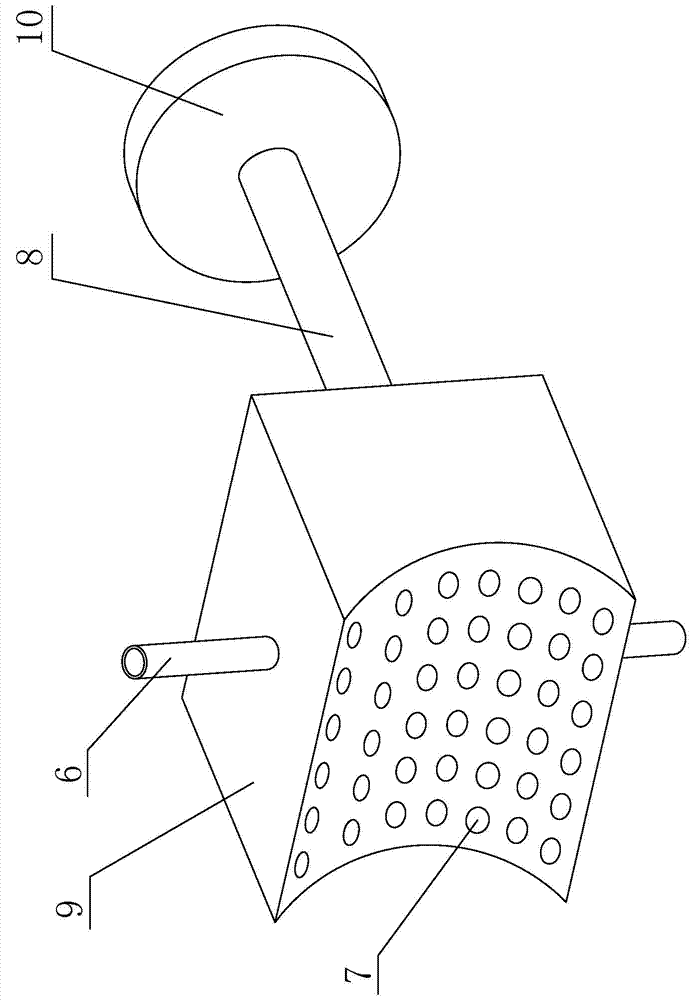

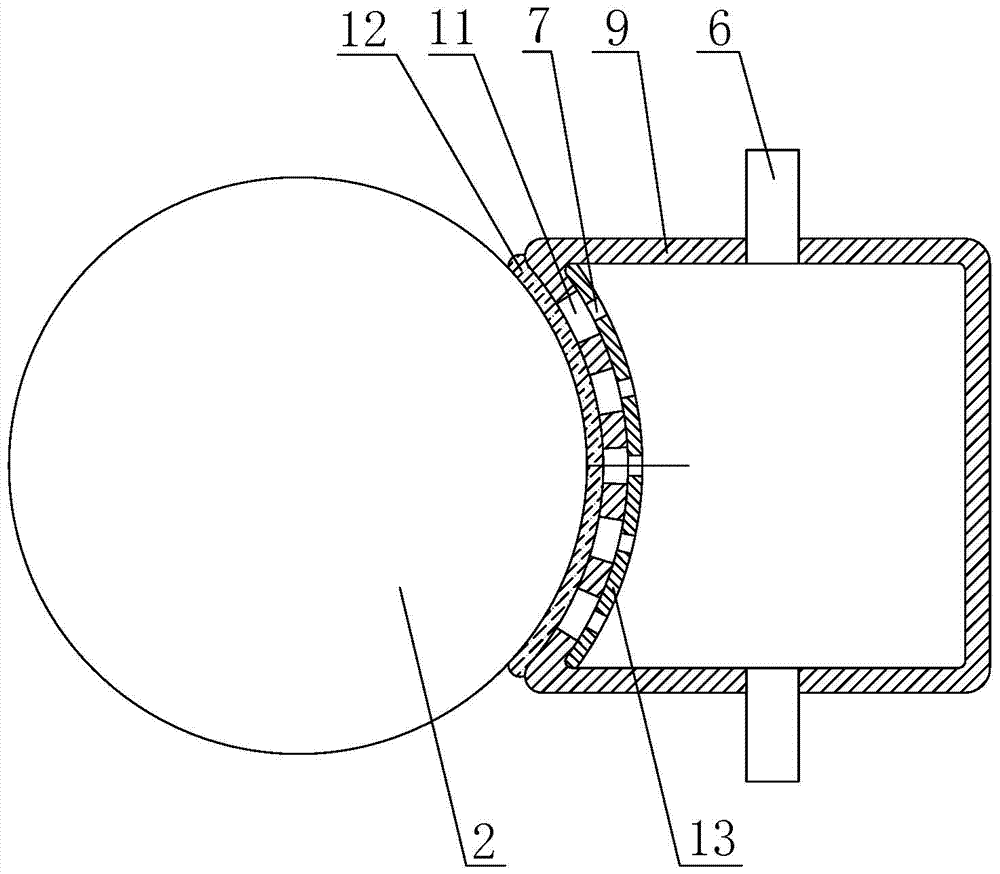

[0020] As shown in Fig. 1 , an embodiment of the textile dyeing press roller for pressure-assisted prevention of uneven pressure at the middle side of the present invention includes a pair of press rollers 1, the outer sides of the press rollers are covered with a rubber layer, and the two sides of the press rollers 1 are respectively provided with The metal roller 2, the axis of the metal roller 2 and the axis of the pressure roller 1 are on the same plane; There is preferably more than one pressing device on the outside of each metal roller 2. When there are multiple briquetting blocks, they can be arranged regularly or irregularly, but the pressing devices on the same metal roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com