Moisture-absorbing and heating alkali-free mercerized fabric and processing method of same

A processing method, alkali mercerizing technology, which is applied in the field of knitting and weft knitting, can solve the problems of airtightness and heavy fabrics, etc., and achieve the effects of enhanced heat preservation, good air permeability and heat retention, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Process and produce moisture-absorbing and heating-type non-alkali mercerized fabrics as follows:

[0030] 1. Selection of raw materials:

[0031] Inner layer material: 32s T / R50 / 50Heatwarm fiber;

[0032] Middle connecting part material: 40s T / R50 / 50Heatwarm fiber;

[0033] Outer material: 32s cotton

[0034] 2. Weaving process:

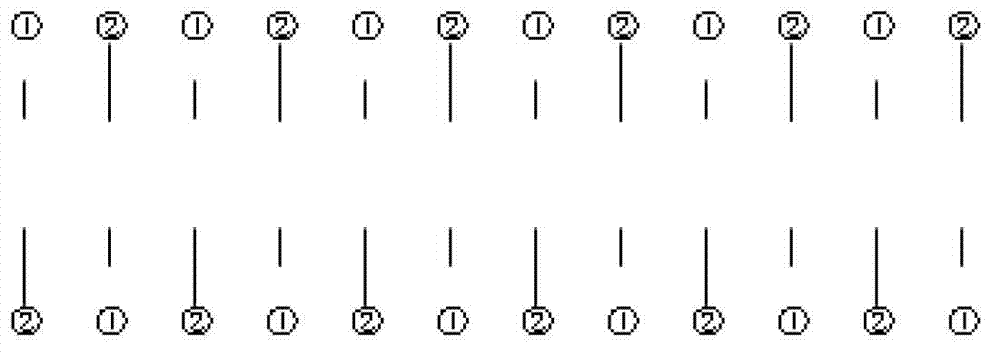

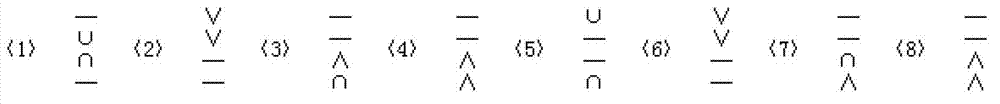

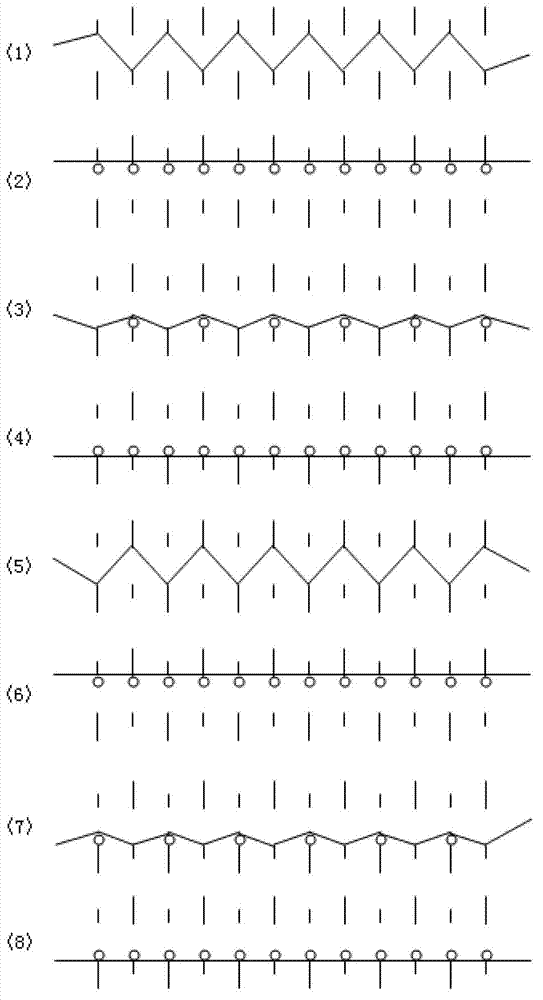

[0035] Choose Meyer-4-11.6QC type double-sided machine, machine number 26#, 18G stitch distance, cylinder diameter 34", knitting needle according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0036] A. Yarn arrangement: 1st, 5th road 40s T / R50 / 50Heatwarm, (intermediate connection layer);

[0037] The 2nd, 6th road 32s pure cotton, (outer layer);

[0038] No. 3, 4, 7, 8 Road 32s T / R50 / 50Heatwarm, (inner layer);

[0039] B. Arrangement of knitting needles: cotton wool to needles;

[0040] 2 stitches...

Embodiment 2

[0064] Process and produce moisture-absorbing and heating-type non-alkali mercerized fabrics as follows:

[0065] 1. Selection of raw materials:

[0066] Inner material: 40s T / R 50 / 50Heatwarm fiber;

[0067] Middle connecting part material: 40s T / R 70 / 30Heatwarm fiber;

[0068] Outer material: 32s cotton

[0069] 2. Weaving process:

[0070] Choose Meyer-4-11.6QC type double-sided machine, machine number 26#, 18G stitch distance, cylinder diameter 34", knitting needle according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0071] A. Yarn arrangement: 1st, 5th road 40s T / R 70 / 30Heatwarm, (intermediate connection layer);

[0072] The 2nd, 6th road 32s pure cotton, (outer layer);

[0073] 3rd, 4th, 7th, 8th road 40s T / R 50 / 50Heatwarm, (inner layer);

[0074] B. Arrangement of knitting needles: cotton wool to needles;

[0075] 2 stitches...

Embodiment 3

[0096] Process and produce moisture-absorbing and heating-type non-alkali mercerized fabrics as follows:

[0097] 1. Selection of raw materials:

[0098] Inner material: 40s T / R 50 / 50Heatwarm fiber;

[0099] Middle connecting part material: 40s T / R 70 / 30Heatwarm fiber;

[0100] Outer material: 32s cotton

[0101] 2. Weaving process:

[0102] Choose Meyer-4-11.6QC type double-sided machine, machine number 26#, 18G stitch distance, cylinder diameter 34", knitting needle according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0103] A. Yarn arrangement: 1st, 5th road 40s T / R 70 / 30Heatwarm, (intermediate connection layer);

[0104] The 2nd, 6th road 32s pure cotton, (outer layer);

[0105] 3rd, 4th, 7th, 8th road 40s T / R 50 / 50Heatwarm, (inner layer);

[0106] B. Arrangement of knitting needles: cotton wool to needles;

[0107] 2 stitch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com