Low-foam and easily bleachable laundry detergent composition and preparation method thereof

A technology for laundry detergent and composition, applied in detergent compositions, detergent compounding agents, chemical instruments and methods, etc., can solve the problems of difficult silicone stability, poor low temperature stability, low Kraff point, etc. Good stain power, good stability and easy rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

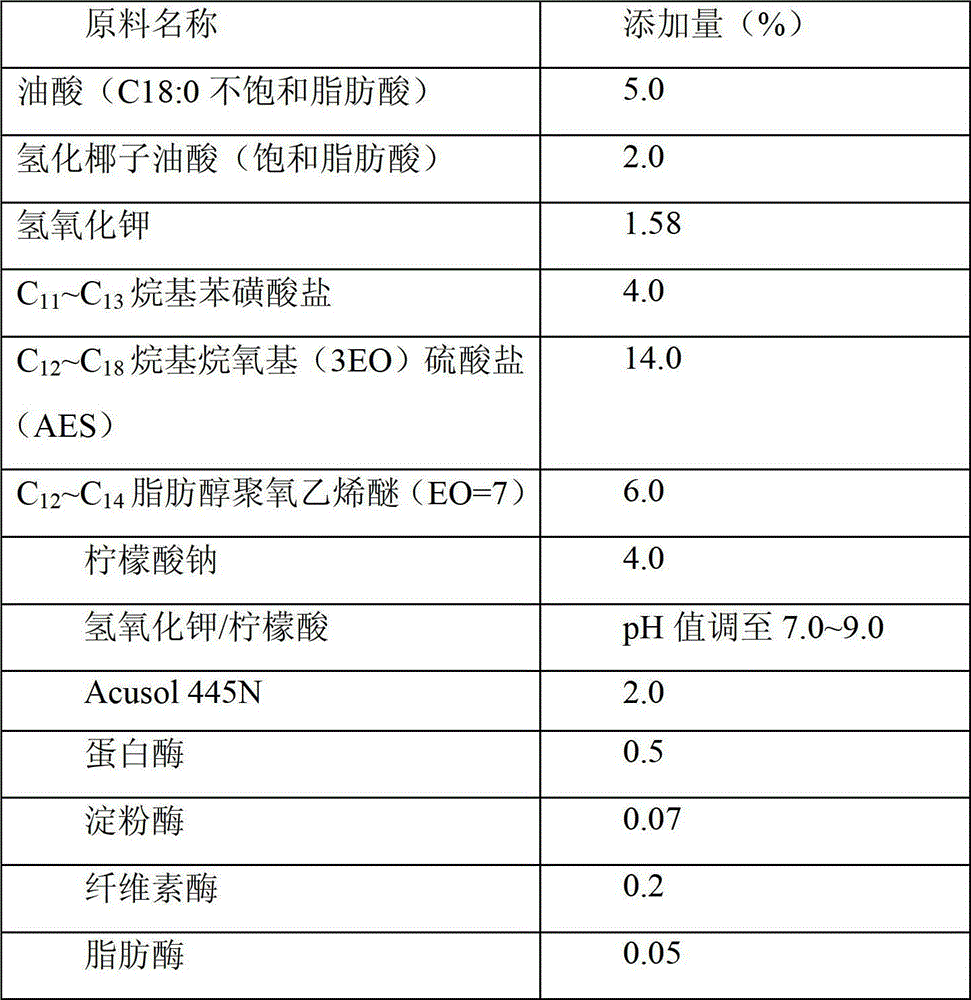

[0096] The composition of laundry detergent in Example 1 of the present invention is as shown in table 4, and the preparation steps of laundry detergent are as follows:

[0097] (1) Add deionized water into the stirring pot, heat to 50°C~60°C, and start stirring;

[0098] (2) Add potassium hydroxide to the stirring pot;

[0099] (3) Add hydrogenated coconut oleic acid and oleic acid into the stirring pot, and stir until the fatty acids in the pot are completely dissolved;

[0100] (4) Add the anionic surfactant into the pot and stir until the anionic surfactant is completely dissolved;

[0101] (5) Add non-ionic surfactant into the pot and stir until the non-ionic surfactant is completely dissolved;

[0102] (6) Adjust the pH value of the laundry detergent in the stirring pot to within the range of 7.0~9.0;

[0103] (7) After the temperature in the stirring pot drops below 45°C, add enzymes, chelating agents, antioxidants, whitening agents, anti-redeposition agents, preserv...

Embodiment 2

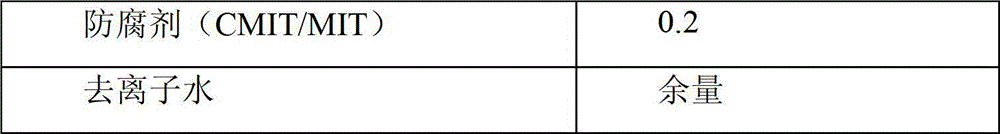

[0108] The composition of the laundry detergent of Embodiment 2 of the present invention is as shown in Table 5, and the preparation steps of the laundry detergent are as follows:

[0109] (1) Add deionized water into the stirring pot, heat to 50°C~60°C, and start stirring;

[0110] (2) Add potassium hydroxide to the stirring pot;

[0111] (3) Add hydrogenated coconut oleic acid and oleic acid into the stirring pot, and stir until the fatty acids in the pot are completely dissolved;

[0112] (4) Add the anionic surfactant into the pot and stir until the anionic surfactant is completely dissolved;

[0113] (5) Add non-ionic surfactant into the pot and stir until the non-ionic surfactant is completely dissolved;

[0114] (6) Adjust the pH value of the laundry detergent in the stirring pot to within the range of 7.0~9.0;

[0115] (7) After the temperature in the stirring pot drops below 45°C, add enzymes, chelating agents, antioxidants, whitening agents, anti-redeposition agen...

Embodiment 3

[0120] The composition of laundry detergent of embodiment 3 of the present invention is as shown in table 6, and the preparation steps of laundry detergent are as follows:

[0121] (1) Add deionized water into the stirring pot, heat to 50°C~60°C, and start stirring;

[0122] (2) Add potassium hydroxide to the stirring pot;

[0123] (3) Add hydrogenated coconut oleic acid and oleic acid into the stirring pot, and stir until the fatty acids in the pot are completely dissolved;

[0124] (4) Add the anionic surfactant into the pot and stir until the anionic surfactant is completely dissolved;

[0125] (5) Add non-ionic surfactant into the pot and stir until the non-ionic surfactant is completely dissolved;

[0126] (6) Adjust the pH value of the laundry detergent in the stirring pot to within the range of 7.0~9.0;

[0127] (7) After the temperature in the stirring pot drops below 45°C, add enzymes, chelating agents, antioxidants, whitening agents, anti-redeposition agents, pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com