Powder feeder

A feeder and powder technology, applied in the field of machinery and equipment, can solve the problems of unfavorable powder feeding, low accuracy of powder quantity, low degree of automation, etc. Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

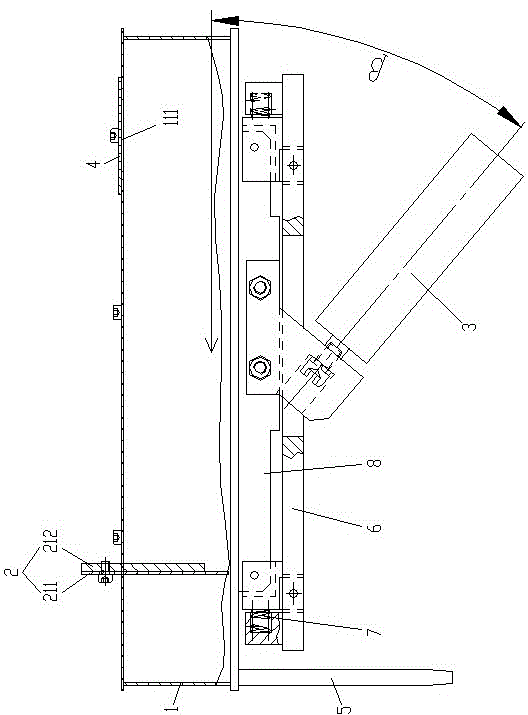

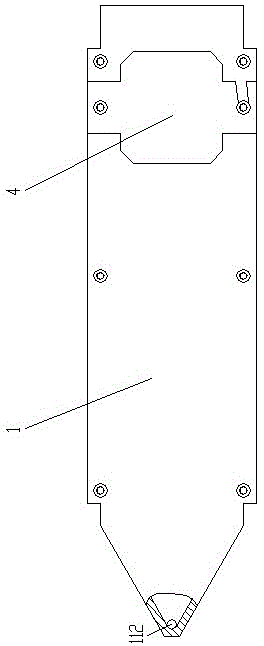

[0024] As shown in the figure, the powder feeder of this embodiment includes a storage tank 1, a powder flow regulating valve 2 arranged on the storage tank 1, and a straight line for vibrating the storage tank located below the storage tank 1. The vibrator 3 is arranged obliquely in a structure that its axial direction and the horizontal advancing direction of the powder in the storage tank intersect at an acute angle.

[0025] In the powder feeder of this embodiment, under the vibration of the linear vibrator 3, the powder makes a parabolic motion in the storage tank 1 and advances in a wave manner, which can eliminate the powder from sticking into agglomerates and make the powder flow The density is uniform and compact, reducing the friction of the powder, ensuring stable operation of the powder, stable flow, and smooth movement, thereby avoiding blockage of the storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com