Method for manufacturing exhaust passage

A technology for exhaust ducts and bottom molds, applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of easy sliding down, high technical proficiency requirements for production workers, and easy sliding down, etc., to achieve low technical proficiency, Wall thickness is easy to control Uniform and easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] like Figure 1-Figure 6 A schematic diagram of the fabrication process of the exhaust duct is shown, Figure 7-Figure 10 Schematic diagram of the removal process of the exhaust duct.

[0031] The exhaust duct preparation process of this embodiment includes:

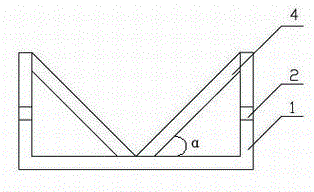

[0032] 1) if figure 1 As shown, the bottom mold fixing frame 1 with the V-shaped bottom mold 4 is placed horizontally, wherein the two sides of the bottom mold fixing frame 1 are respectively provided with supporting feet 2;

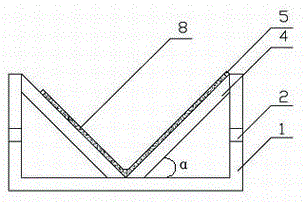

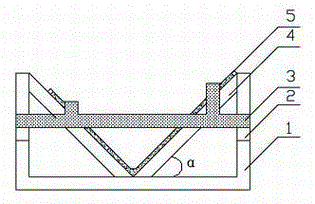

[0033] 2) if figure 2 As shown, the wall thickness positioning strip 5 is selected according to the wall thickness, side length and length of the exhaust duct to be prepared and placed on the corresponding positions at the sides and two ends of the two inner surfaces of the V-shaped bottom mold 4 On, spray release agent, smear the gel material between the wall thickness positioning strips 5 on the two inner sides of the V-shaped bottom mold 4, and scrape the gel material with a V-shaped...

Embodiment 2

[0043] The exhaust duct preparation process of this embodiment includes:

[0044] Steps 1)-8) are the same as in Example 1;

[0045] 9) if Figure 11 As shown, after removing the positioning bar 5, directly take out the exhaust duct 8 with the top mold 7;

[0046] 10) If Figure 12 As shown, the top mold 7 is taken out to obtain the exhaust duct 8, which can be maintained.

Embodiment 3

[0048] The exhaust duct preparation process of this embodiment includes:

[0049] 1) Place the bottom mold fixing frame 1 with the V-shaped bottom mold 4 on the horizontal surface, set the wall thickness positioning strips 5 on the inner sides of the V-shaped bottom mold 4, and the wall thickness positioning strips 5 prepare the sides of the exhaust duct according to the needs length, length and wall thickness are selected and placed on the sides of the two inner surfaces of the bottom mold 4 and the corresponding positions at the two ends;

[0050] 2) Spray the release agent, and then apply the gelling material between the wall thickness positioning strips 5 on the two inner sides of the V-shaped bottom mold 4, and scrape it flat with a V-shaped scraper;

[0051] 3) After the gelling material is finally set, remove the positioning strip and take out the exhaust duct assembly;

[0052] 4) Repeat the above steps to prepare another exhaust duct assembly;

[0053] 5) Glue the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com