Wood-base photochromic composite preparation method

A composite material and photochromic technology, which is applied in the field of preparation of organic photochromic materials, can solve the problems of not having photochromic function, and achieve the effect of fast photoresponse time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

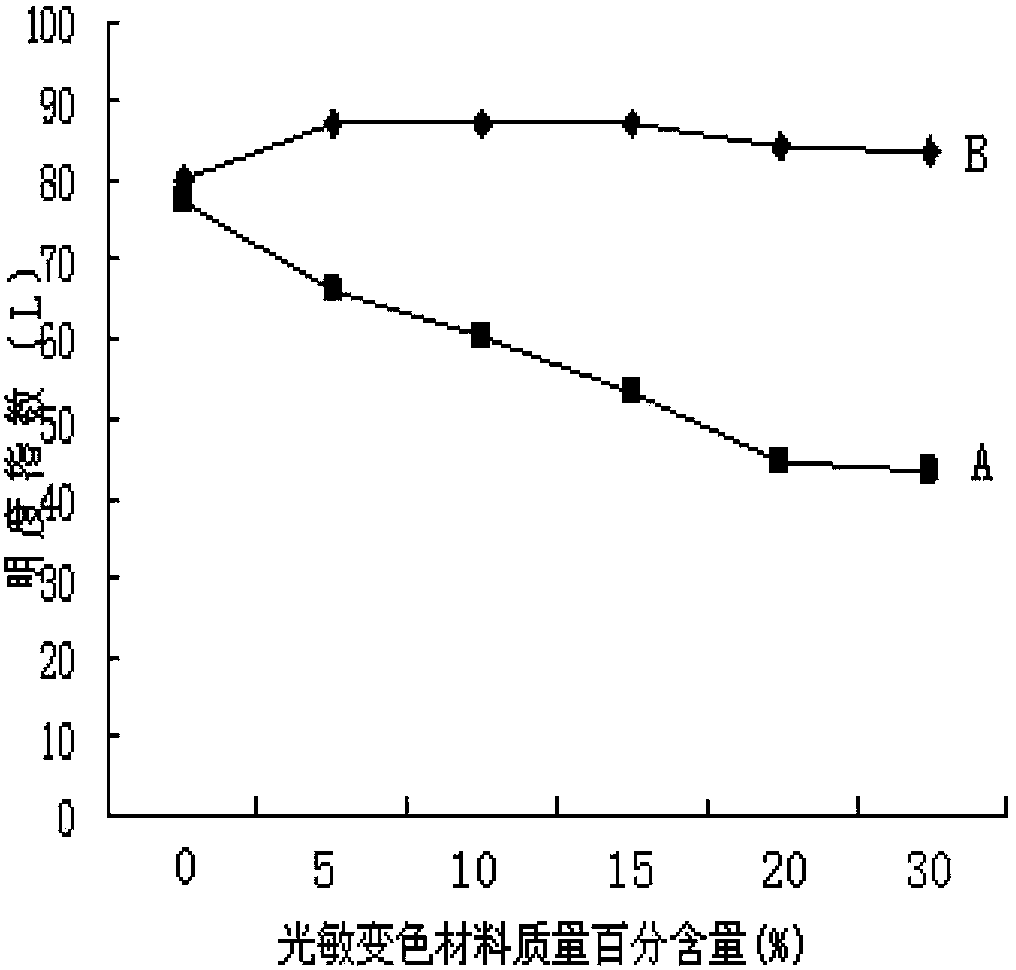

[0023] Embodiment 1: The preparation method of a kind of wood-based photosensitive color-changing composite material of this embodiment is carried out according to the following steps:

[0024] 1. Polish the wood surface to be smooth, then place the wood in anhydrous acetone, absolute ethanol and deionized water for 5 to 30 minutes of ultrasonic cleaning respectively, and let it dry naturally to obtain the wood matrix;

[0025] 2. Add polyvinyl alcohol powder into deionized water, stir and dissolve it in a water bath at 70-85°C, and prepare an aqueous solution of polyvinyl alcohol with a mass percentage of polyvinyl alcohol of 2%-8%;

[0026] 3. Ultrasonic dispersion and dispersion of the organic photochromic material in the polyvinyl alcohol aqueous solution obtained in step 2, to prepare an organic photochromic material / polyvinyl alcohol film-forming liquid with a mass percentage of the organic photochromic material of 2% to 50%;

[0027] 4. Immerse the organic photosensitiv...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that an aqueous solution of polyvinyl alcohol with a mass percentage of polyvinyl alcohol of 4% is prepared in Step 2, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the degree of polymerization of polyvinyl alcohol described in step two is 1700-1800, the degree of alcoholysis is 98%-99%, other steps and parameters It is the same as the specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com