Turntable-type multi-station pen point automatic processing machine tool with pipe contraction function

An automatic processing, turntable technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of easy occurrence of burrs, increased cost, and uneven surface of the pipe material, and achieves accurate size, reduced pipe diameter, and smooth surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

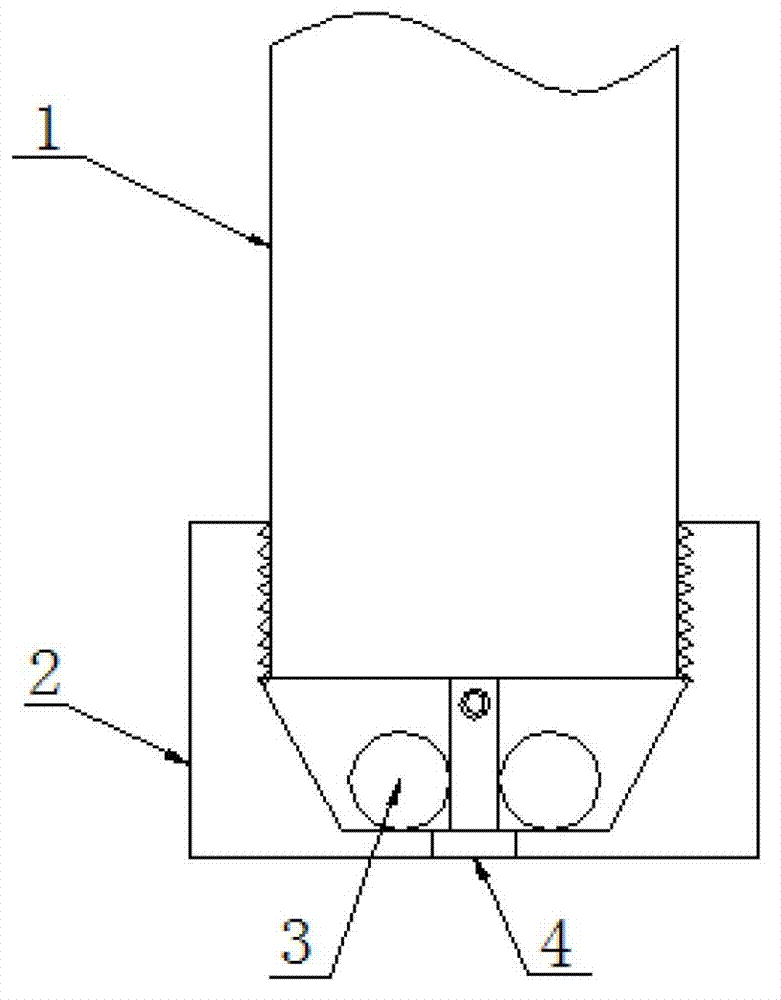

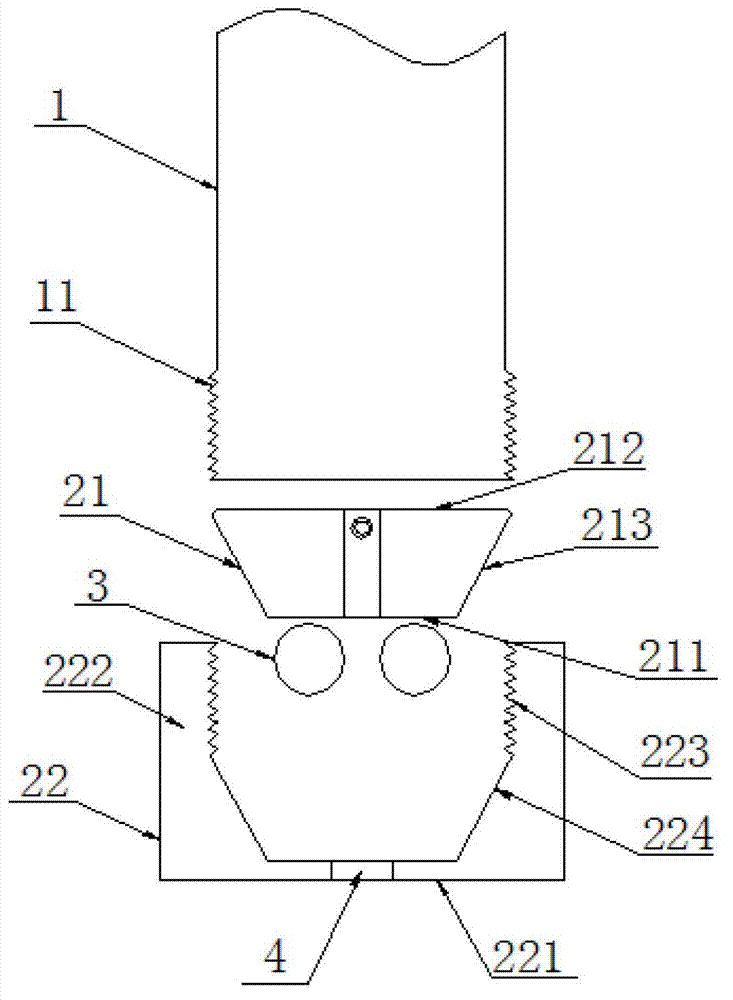

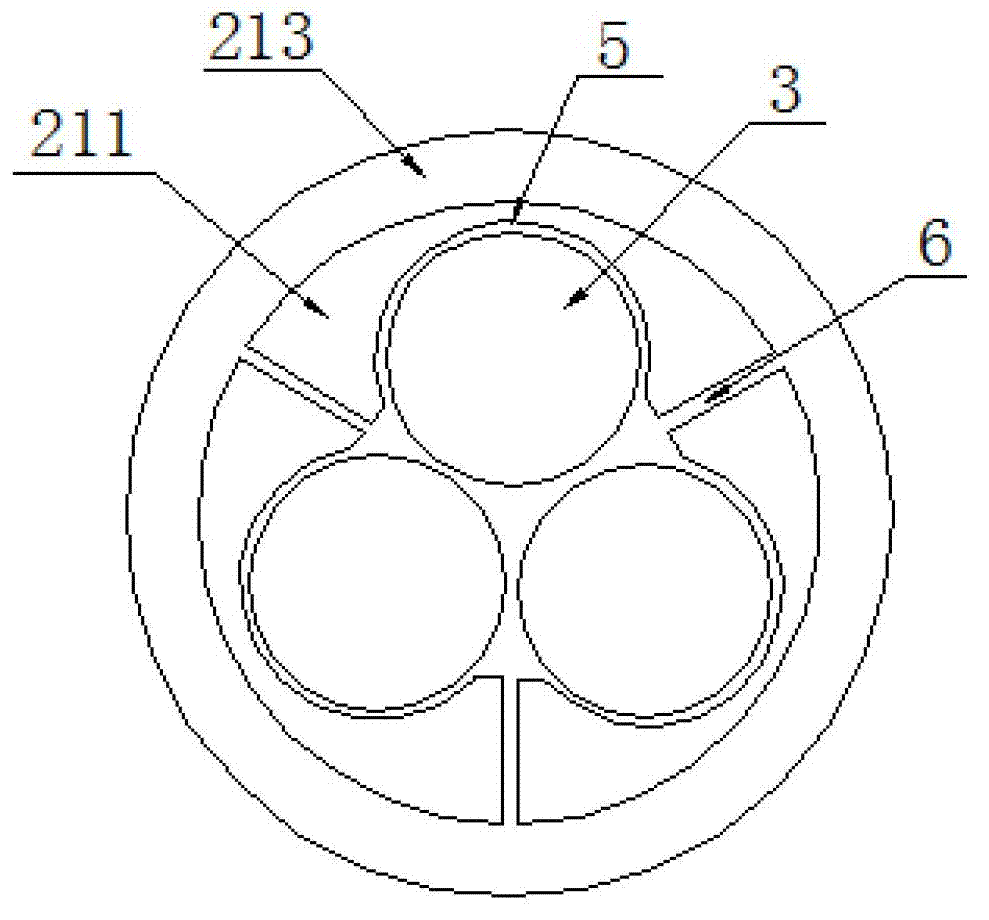

[0022] Embodiment: a turntable type multi-station nib automatic processing machine tool with shrink tube function, with an external machine cover, an upper bed, a lower bed and a rotary worktable are arranged inside the machine cover, and several stations are divided into upper and lower The lower two rows of processing mechanisms are evenly distributed above and below the rotary table. The upper row of processing mechanisms is located on the upper bed, and the lower row of processing mechanisms is located on the lower bed. The positions of the upper and lower rows of processing mechanisms correspond to each other. The material is fixed on the rotary table, and the processing mechanism performs vertical processing on the pen material. The rotary table can rotate the pen material to the next station, and each processing mechanism is installed at the end of each power head. The transmission mechanism and power equipment that drive the rotation of the rotary table and the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com