High-temperature bag type pulsed dust collector

A pulse dust collector and bag-type technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of uneven dust collector, difficulty in adapting to high temperature gas dust removal, enterprise loss, etc., and achieve distribution Uniform, conducive to high-efficiency dust removal, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

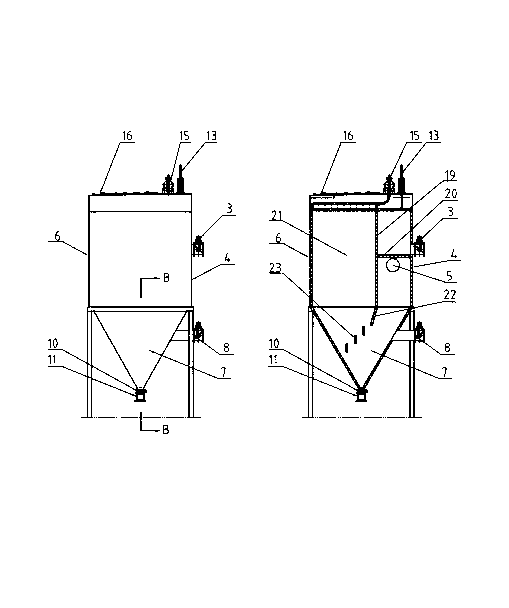

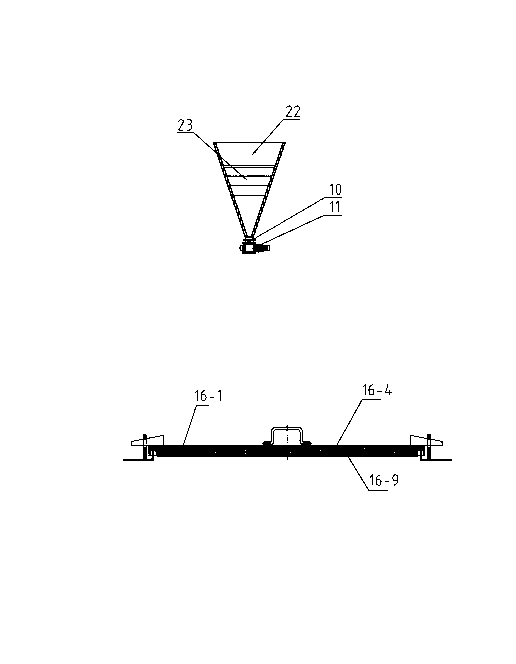

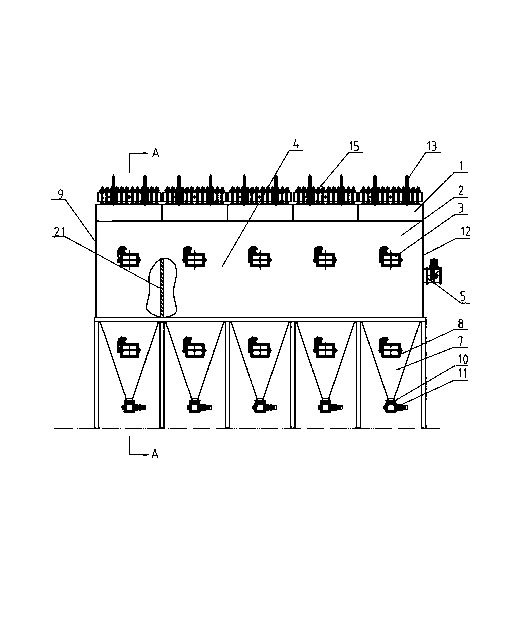

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

[0020] In the embodiment shown in the figure, a high-temperature bag-type pulse dust collector includes an upper injection system, an upper box 1, a plurality of lower ash hoppers 7, and a middle box front side plate 4, a middle box rear The middle box 2 surrounded by the side plate 6, the left side panel 9 of the middle box, the right side plate 12 of the middle box and the top flower plate 14, the top of the upper box 1 is provided with a door cover 16, and the upper box 1 is provided with The upper blowing system, the pneumatic poppet valve 13, the inner side of the middle box 2 is provided with an air duct vertical partition 19, the air duct vertical partition 19 forms an air duct with the front side plate 4 of the middle box, and the air duct is provided with a horizontal The partition plate 20 divides the air duct into two air chambers, the upper air chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com