Cotton separation device of cotton picking machine

A technology for picking machines and removing cotton, applied in the directions of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of long conveying distance of cotton, clogging the shell, easy clogging, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

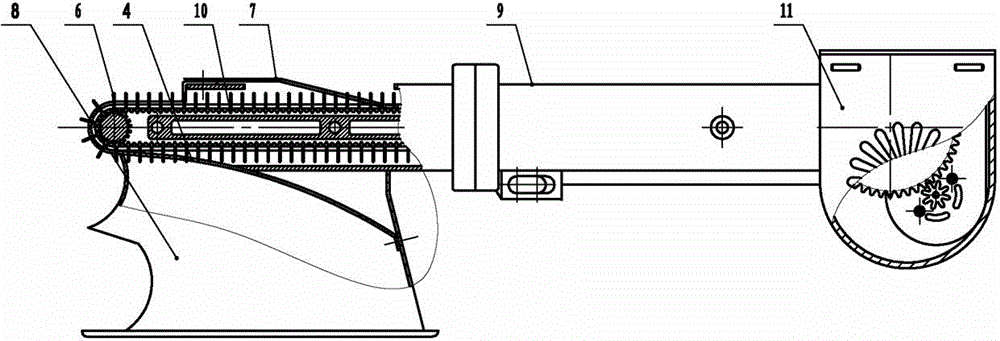

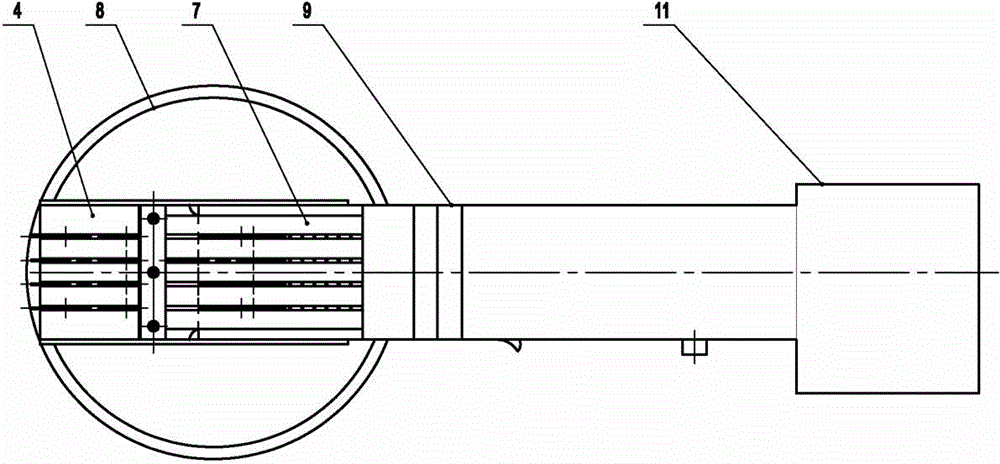

[0026] Depend on figure 1 , figure 2 It can be seen that a cotton picking machine decotton device comprises a housing 9, a belt 10 driven by power (the present embodiment is a motor 11) is installed in the housing 9, a picking needle 6 is installed on the belt 10, and the housing 9 One end of the picker is the picking mouth, and the cotton feeding pipe 8 is installed at the picking mouth. , The housing 9 is also equipped with an auxiliary doffer plate arranged behind the doffer plate, and the other end of the housing 9 is equipped with a motor 11 and a transmission mechanism.

[0027] The present invention has simple structure and convenient installation. According to the moving direction of the picking needle 6, the auxiliary doffer plate is installed in front of the picking mouth.

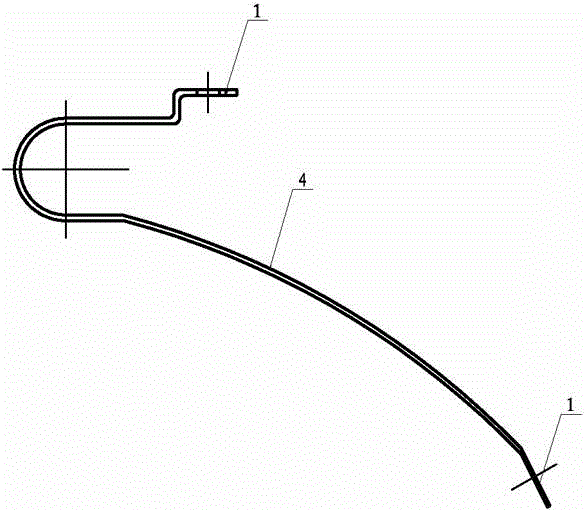

[0028] Depend on image 3 , Figure 4 , Figure 5 It can be seen that the doffer plate of the present invention comprises a doffer plate body 4, the doffer plate body 4 is sheet-shaped, and...

Embodiment 2

[0037] In order to prevent cotton from entering the casing 9 and blocking the motor 11 and the transmission device, the auxiliary doffer plate of the present invention is installed in the cotton delivery pipe 8 to form a double-layer doffing structure with the doffer plate. The cotton collected by the picking needle 6 is completely separated from the picking needle 6 through the doffer plate in the cotton delivery pipe 8 and the double layer of the auxiliary doffer plate, and is sent out through the cotton delivery pipe 8, and the remainder is the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com