Electric drive unit

An electric drive unit, the technology of the drive unit, applied in the direction of electric components, electrical components, connection with control/drive circuits, etc., can solve the problem of necessary cooling, and achieve the effect of low additional cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

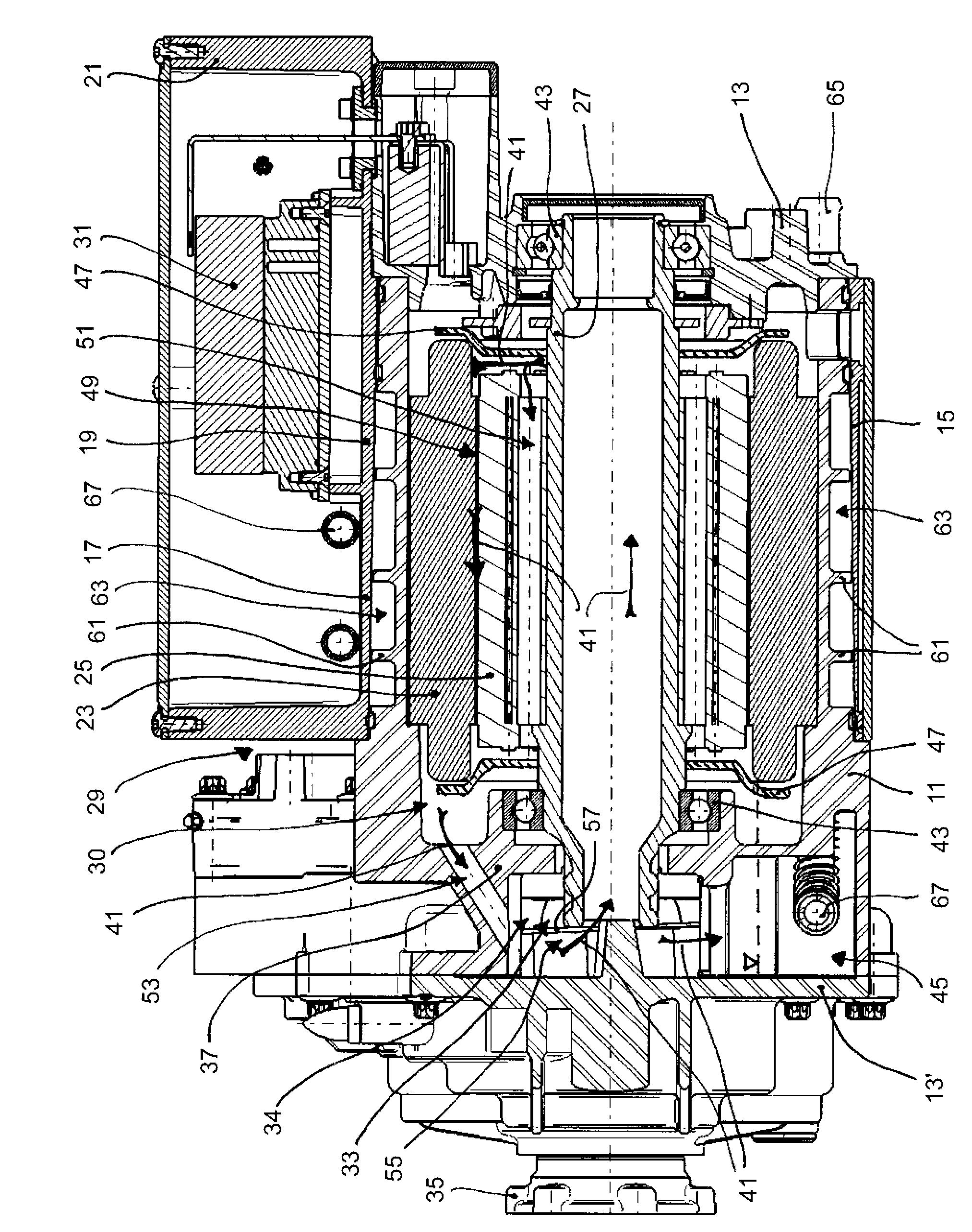

[0023] The electric drive unit shown comprises a metal housing 11 which is closed at its two end sides by housing covers 13 , 13 ′ in each case. The metal shell 11 is preferably cast from aluminum. Furthermore, the electric drive unit has a plastic housing 15 with a cylindrical outer surface 17 , which surrounds a cylindrical outer surface 19 of the metal housing 11 on all sides. Furthermore, the plastic housing 15 has a cuboid circuit housing section 21 mounted on the upper side.

[0024] Inside the outer peripheral surface 19 , the stator 23 is inserted, for example pressed, into the metal shell 11 . Arranged within the stator 23 is a rotor 25 which is connected in a rotationally fixed manner to a hollow output shaft 27 which is rotatably mounted in the metal housing 11 . The stator 23 and the rotor 25 form a motor 29 , in particular a three-phase asynchronous motor. The motor 29 is provided in the engine room 30 of the metal case 11 . A circuit including, for example, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com