Hydrodynamically guided circular saw blade

A technology of circular saw blade and support body, which is applied to metal sawing equipment, attachments of sawing machines, tools of sawing machines, etc., can solve problems such as damage to the quality of the sawing process, and achieve the effect of reducing vibration and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

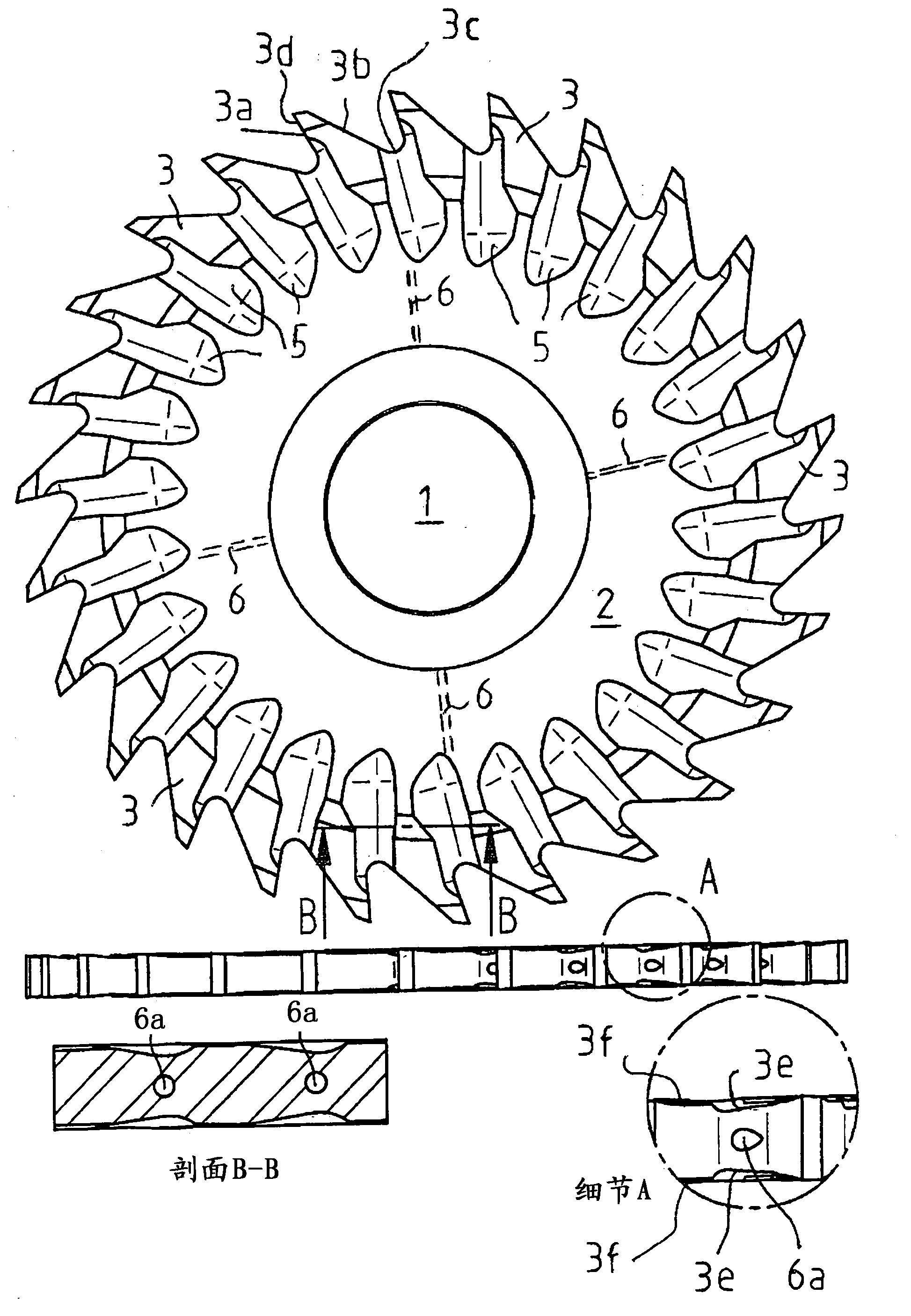

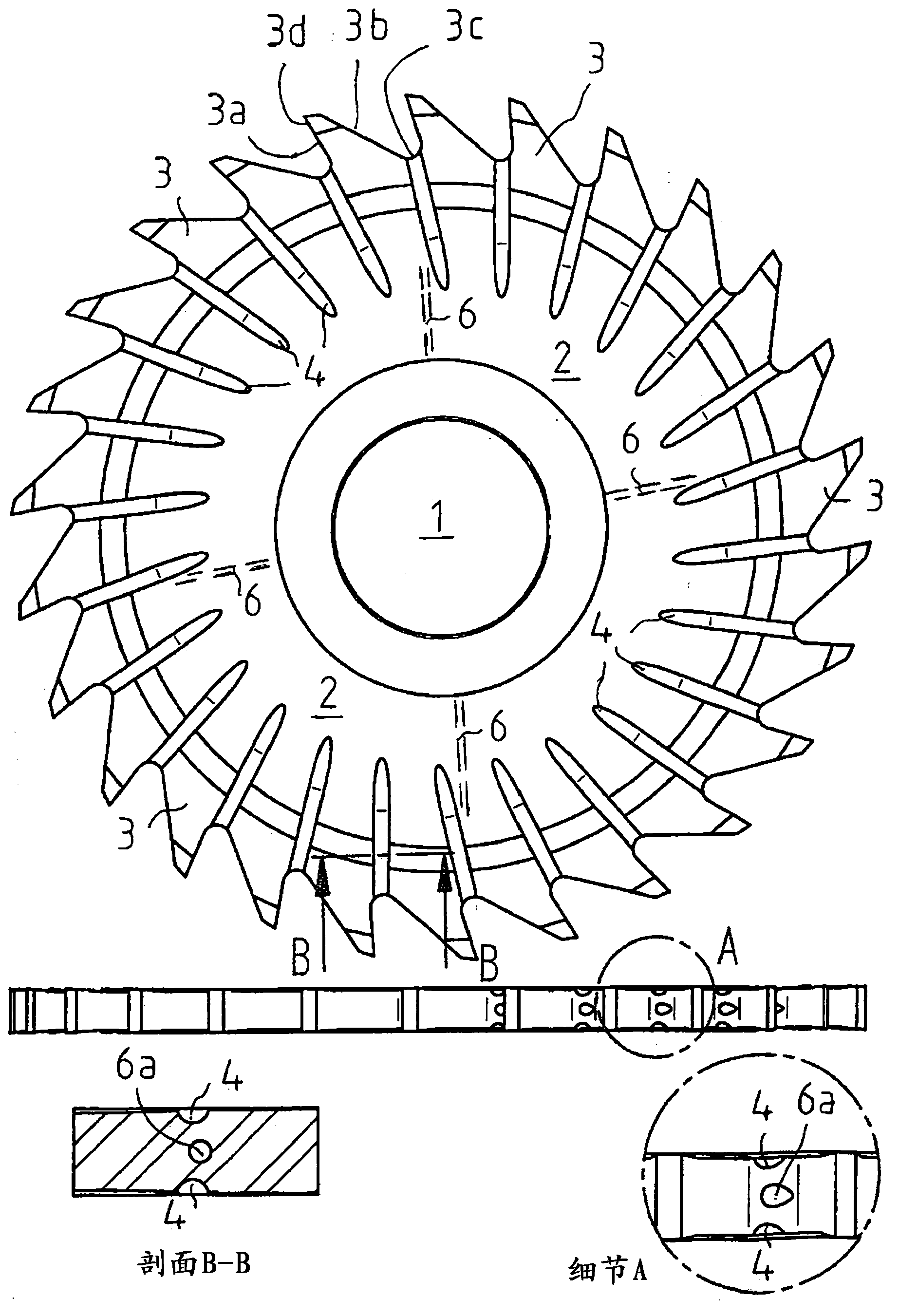

[0011] figure 1 A schematic view of a circular saw blade according to a first exemplary embodiment of the invention is shown. The circular saw blade has a central hole 1 in its central region, so that it can be fixed on a shaft of the circular saw. Furthermore, the circular saw blade includes a carrier body 2 made of cemented carbide, ceramic or steel. A plurality of cooling channels 6 distributed in the radial direction are arranged in the inner region of the carrier body 2, wherein, in figure 1 Only four of these cooling channels are marked with dashed lines in .

[0012] In the area of the outer circumference of the carrier body 2 are provided a plurality of teeth 3 which each have a front flank 3a, a rear flank 3b, a dedendum 3c, a cutting edge 3d, a narrowing region 3e and a Again widened area 3f.

[0013] During saw operation, cooling fluid is conducted via the cooling channel 6 into the working region of the circular saw blade and is discharged there from the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com