Method of positioning transformer in frequency converter cabinet

A technology of transformers and frequency converters, which is applied in the direction of transformer/reactor installation/support/suspension, switchgear, electrical components, etc. It can solve the problems of large beam bearing capacity and easy deformation, transformers are easy to dump, and high cost of measures, and achieve manpower and material resources. The effect of less investment, high installation efficiency, and reduced installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] A method for placing a transformer in a frequency converter cabinet, comprising the following steps:

[0026] First prepare the tools:

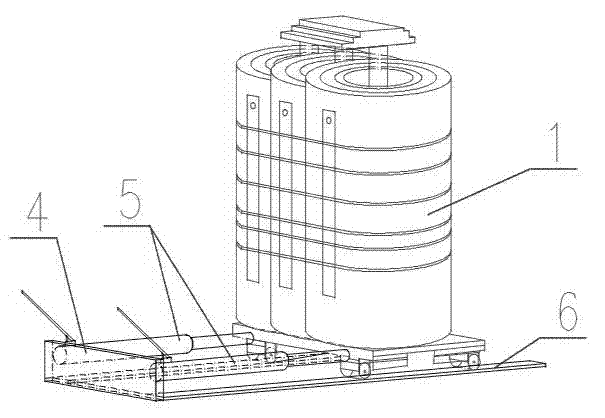

[0027] According to the weight of the transformer 1, select two suitable electro-hydraulic jacks, two hydraulic push rods 5 and two 400*400*14mm steel plates as gaskets for the electro-hydraulic jack, and make two Ω-shaped ones made of 10# channel steel Lifting bracket 2, two sets of fixtures 4 and two 1m long guide rails 6 made of 16# channel steel;

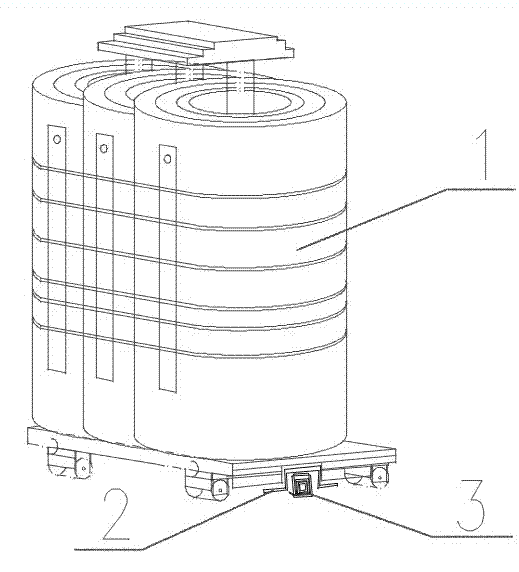

[0028] Then the transformer 1 is jacked up, figure 1 It is a schematic diagram of transformer 1 jacking of the present invention, and the specific jacking process is:

[0029] Set two Ω-shaped lifting brackets 2 in the steel plate grooves protruding upwards from the bottom in the middle of the iron cores on both sides of the transformer 1, and use two jacks 3 with st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com