Pixel structure of display panel and manufacturing method thereof

A technology of pixel structure and manufacturing method, used in static indicators, nonlinear optics, instruments, etc., can solve the problems of short circuit, the pixel aperture ratio cannot be effectively improved, and the panel cannot display images normally, and achieves the improvement of the pixel aperture ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

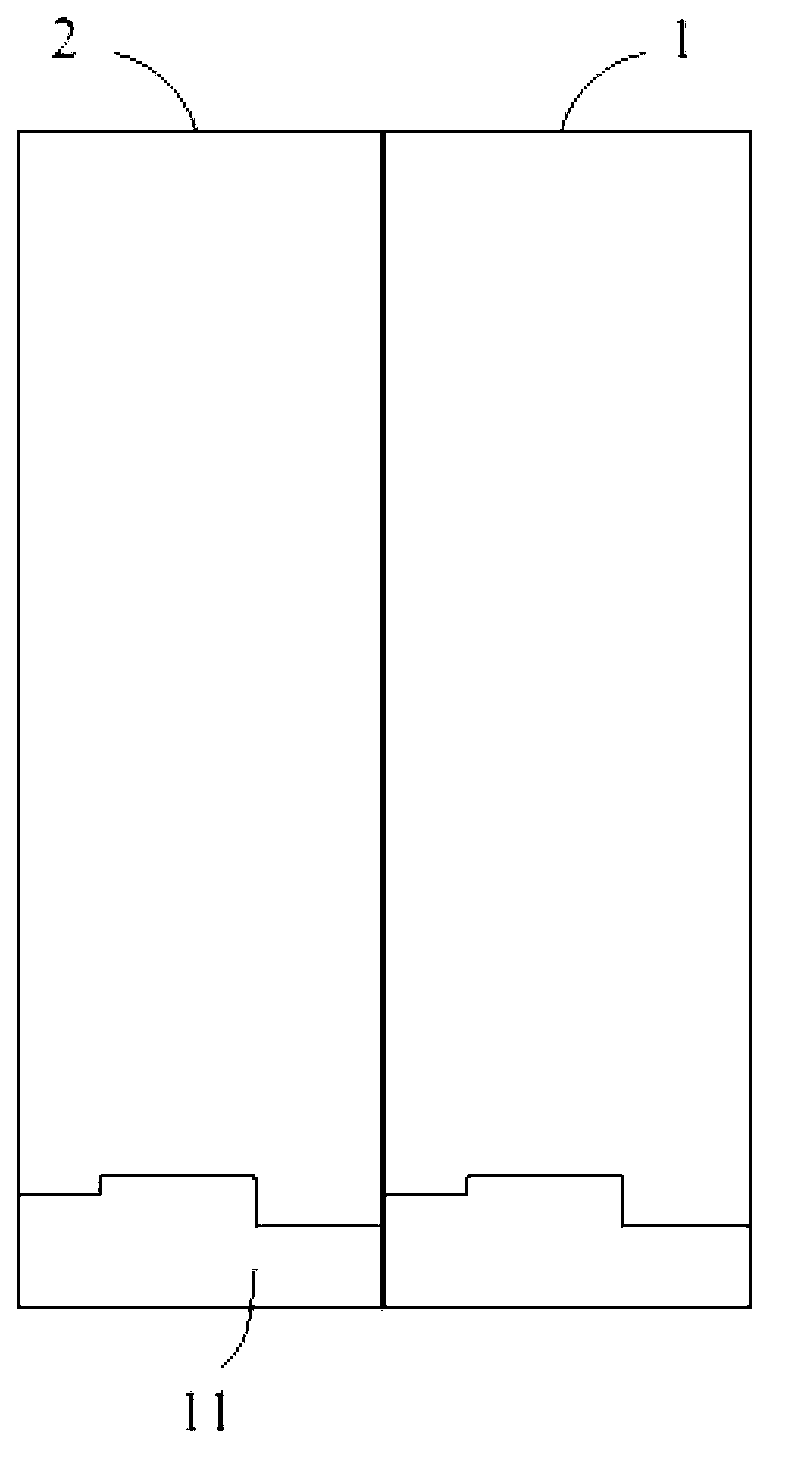

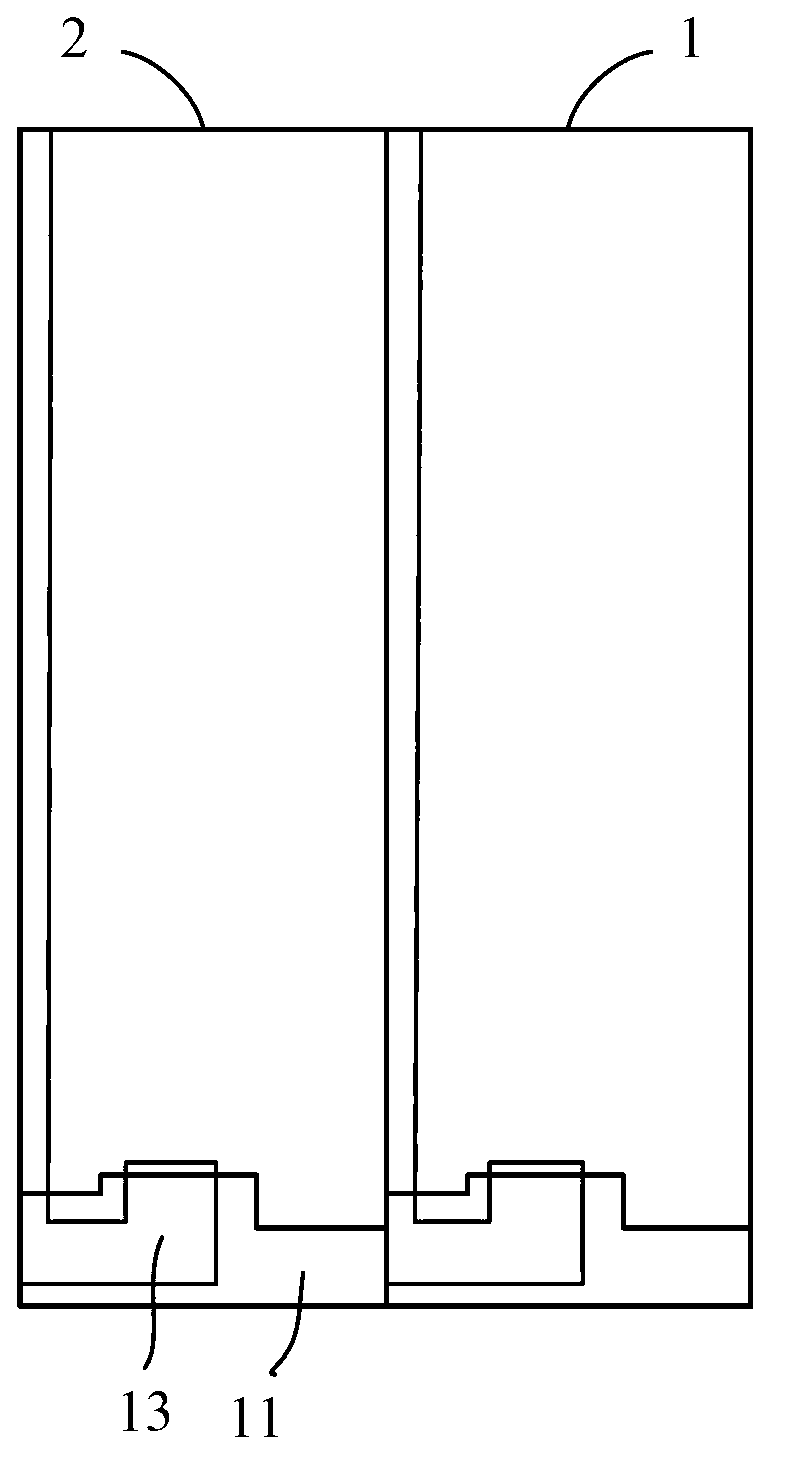

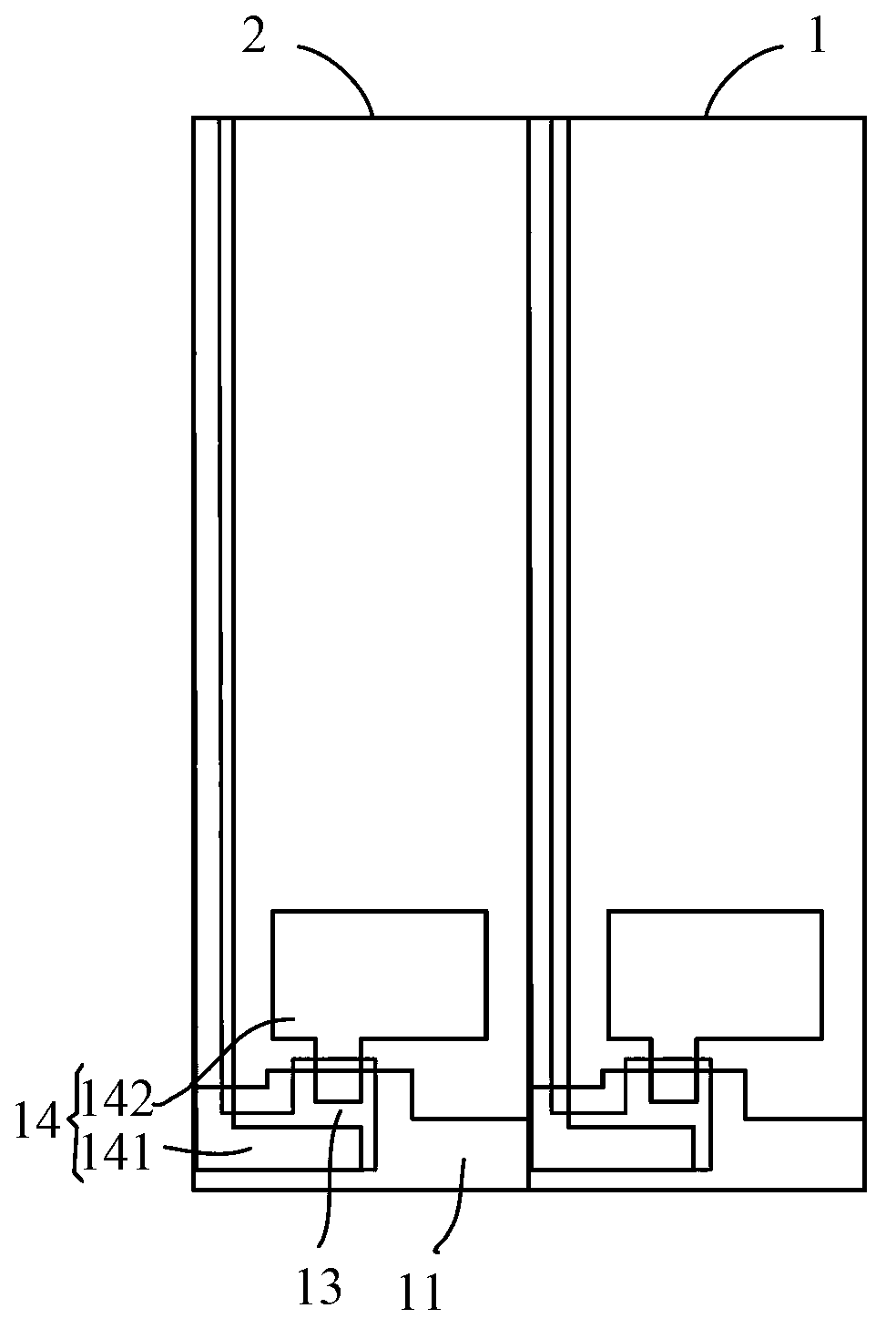

[0032] The present invention relates to a pixel structure of a display panel and a manufacturing method thereof, which is characterized in that the pixel electrodes in two adjacent pixel areas are arranged at different levels. It can also be said that the two pixel electrodes are formed at different heights. layer, whereby the horizontal spacing between the pixel electrodes in two adjacent pixel areas can be reduced compared to the spacing specified in the manufacturing process, that is to say, the area occupied by the pixel electrodes is relatively larger, so the present invention can effectively Increase opening rate. On the other hand, in the present invention, a conductive layer (or metal conductive layer) can be arranged at the junction of two adjacent pixel areas, and the conductive layer can respectively form a storage capacitor with the pixel electrodes in the two adjacent pixel areas, and the conductive layer can also The coupling effect of two adjacent pixel electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com