Cooling tower collapse analog experiment device

A simulation test, cooling tower technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem that there is no quantitative analysis of the collapse of super-large cooling towers, and achieve the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

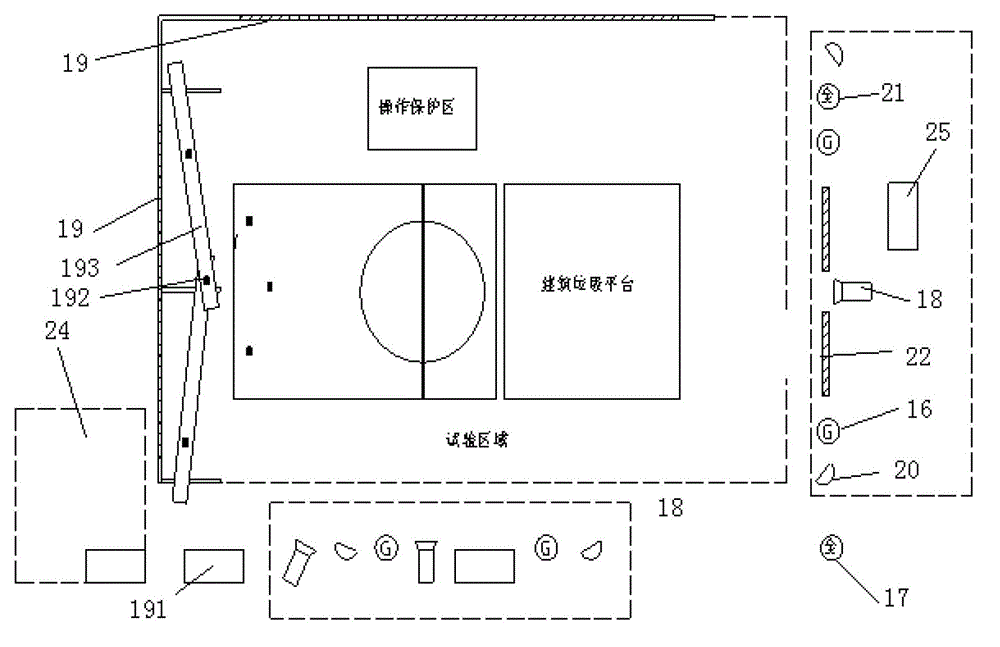

[0033] Such as figure 1As shown, the cooling tower collapse simulation test device of the present invention includes a cooling tower model 11, a data acquisition device, a data processing device, a plurality of pillars 12, a pedestal 14, a column support device 13 and a support plate 15, and the data acquisition device Connected with the data processing device, the data acquisition device is arranged in front of the collapse direction of the cooling tower model 11 and perpendicular to the collapse direction of the cooling tower model 11, during the collapse of the cooling tower model 11, The data collection device collects various parameters of the cooling tower model 11 and transmits them to the data processing device for processing, which is an important basis for the actual safety of the cooling tower. A part of the bottom of the cooling tower model 11 is supported on the pedestal 14 by a plurality of the pillars 12, and the other part of the cooling tower model 11 is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com