Gate valve

A technology for gate valves and valve bodies, which is applied to sliding valves, valve devices, engine components, etc., and can solve problems such as bruised gate valves, sealing surface angles, uneven sealing surfaces, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

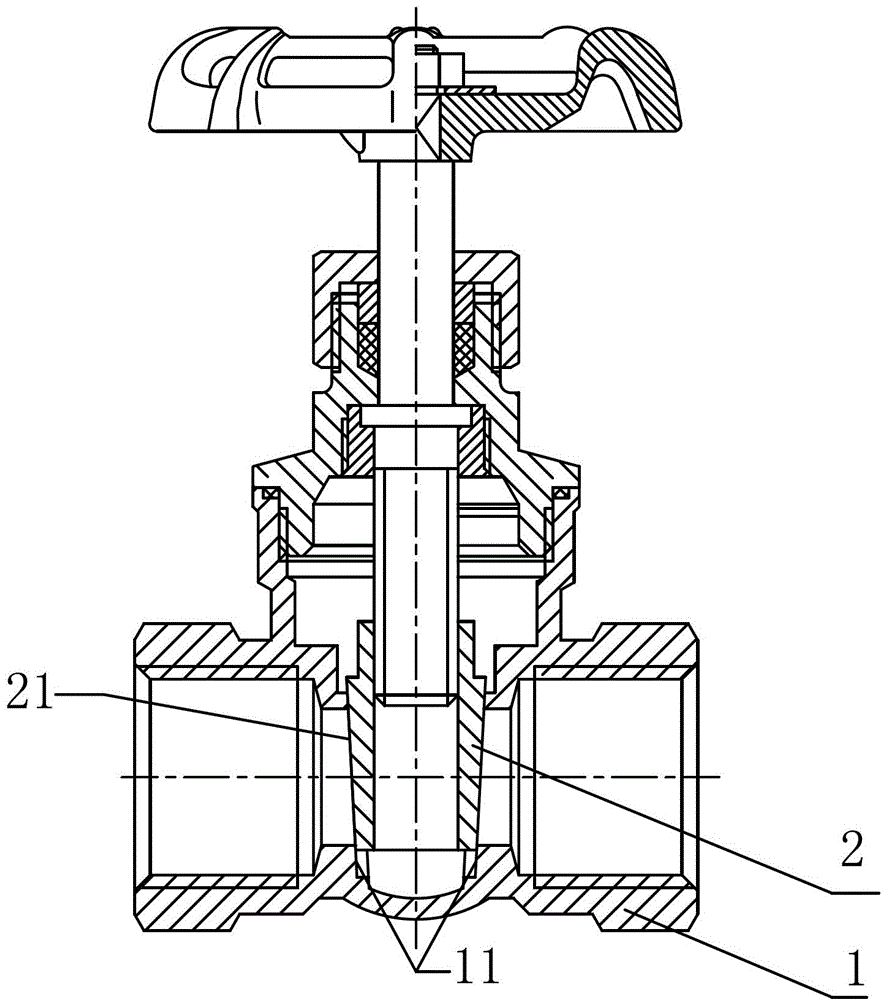

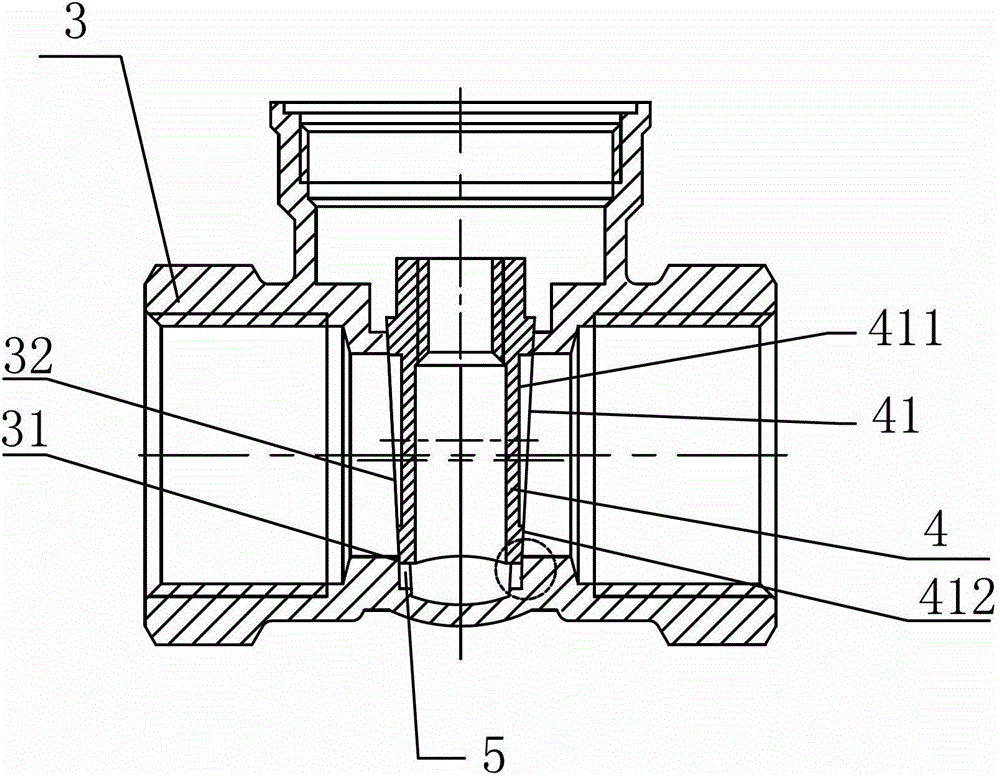

[0015] Such as Figures 2 to 5 Shown is a gate valve of the present invention, including a valve body 3 and a wedge gate 4, the wedge gate 4 is installed in the valve body 3 and can move between an open position and a closed position, and the wedge gate The gate 4 is provided with two gate sealing surfaces 41 , and the angle between the two gate sealing surfaces 41 is the wedge angle of the wedge gate 4 .

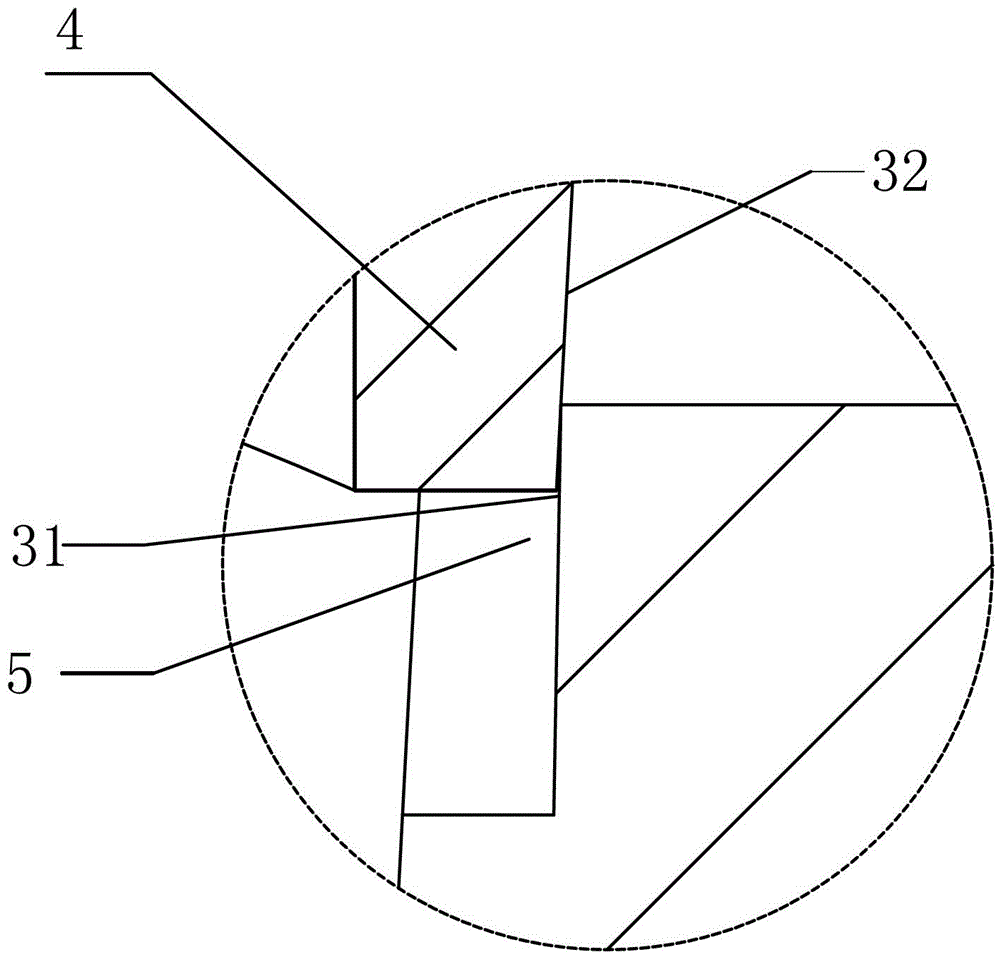

[0016] The valve body 3 is provided with a sealing part that cooperates with the gate sealing surface 41, and the sealing part includes the first sealing surface 31 at the bottom of the valve body 3 and the second top-down bottom of the valve body. The sealing surface 32 , the first sealing surface 31 and the second sealing surface 32 form an included angle α. Wherein, the upper parts on both sides of the first sealing surface 31 are in contact with the lower parts of the second sealing surface 32 . When the gate valve is in a closed state, the second sealing surface 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com