Heat-sealing packaging device and transverse sealing cutting unit thereof

A cutting device and horizontal sealing technology, applied in packaging sealing/tightening, packaging, transport packaging, etc., can solve the problems of easy wear and tear of cutting knives, rolling elements, inability to achieve adjustment effects, and high equipment replacement costs. The effect of less wear and increased stress area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

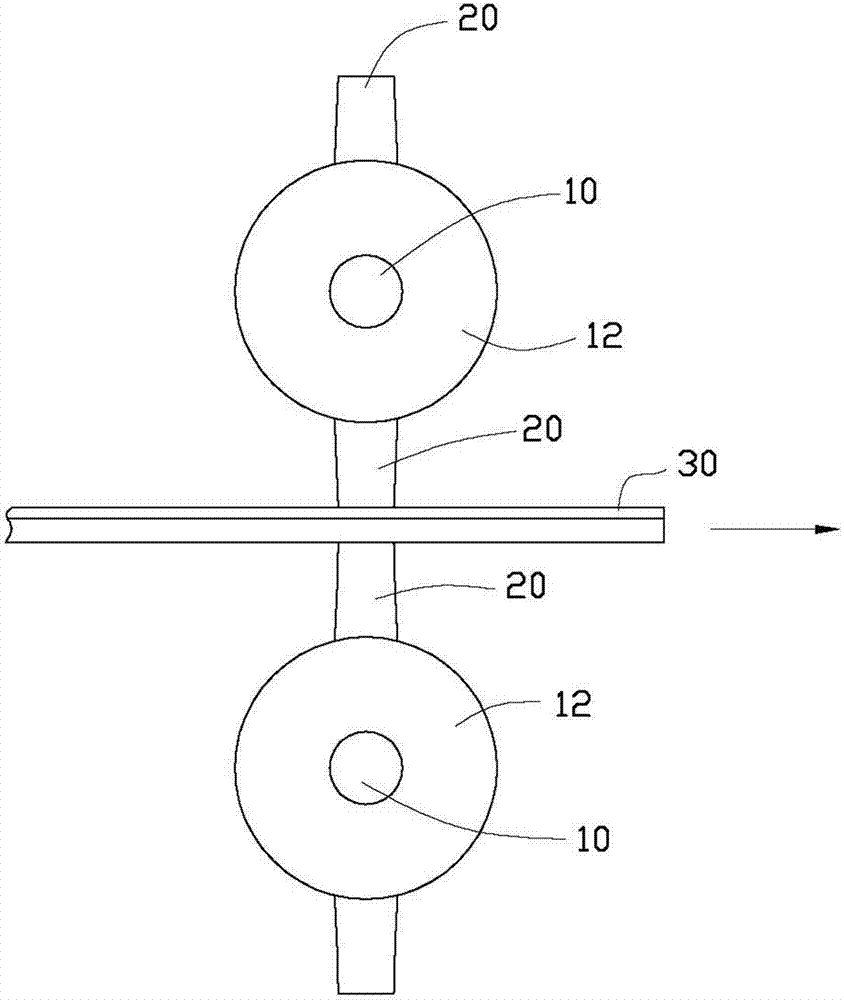

[0020] Please refer to figure 1 , The horizontal sealing and cutting device of an embodiment of the present invention includes horizontal sealing shafts 10 arranged in pairs, flower scissors 12 arranged on the horizontal sealing shafts 10 , and several heat-pressing sealing heads 20 evenly distributed on the circumferential direction of the flower shears 12 . The packaging material 30 passes between the two rotating horizontal sealing shafts 10, advances in the direction indicated by the arrow in the figure, and passes through the sealing surface between the corresponding two heat sealing heads 20 to complete the heat sealing and cutting operations. Since the structures of the two horizontal sealing shafts 10, the flower scissors 12 and the heat-pressing sealing heads 20 on the flower shears 12 are respectively the same, only the structure of the heat-pressing sealing head 20 on one of the flower shears 12 will be described below.

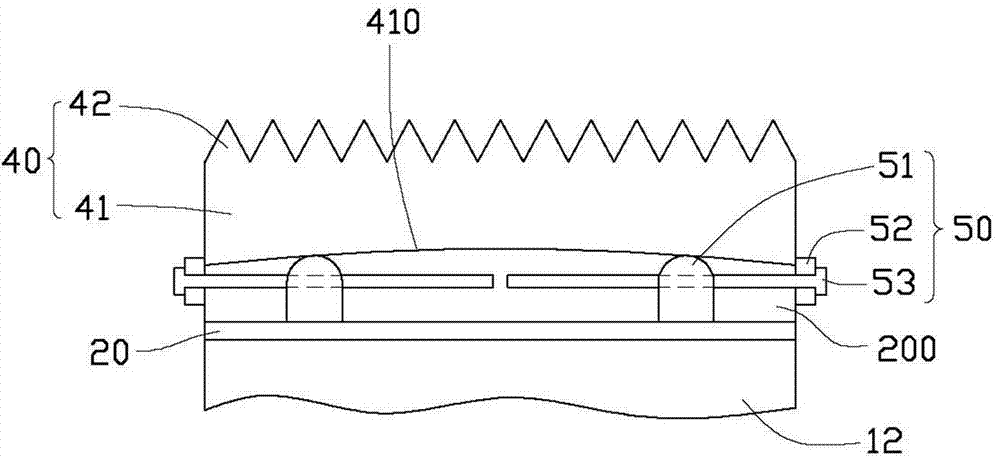

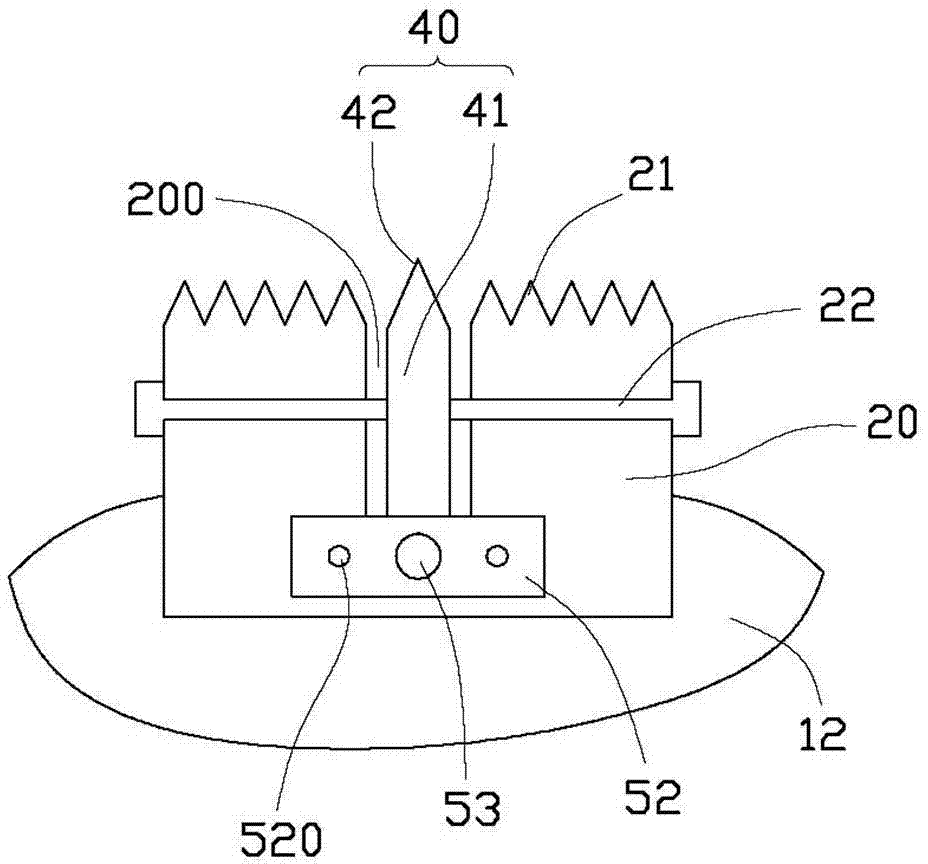

[0021] The horizontal sealing and cutting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com