Fast growing wood flame retardant enhanced solid wood section material and its manufacturing method

A manufacturing method and technology of fast-growing wood, which are applied in the directions of manufacturing tools, wood compression, wood treatment, etc., can solve the problems of poor dimensional stability of flame-retardant profiles, not resistant to decay, service life, prone to mildew and blue change, etc., and achieve dimensional stability. Good effect, strong corrosion resistance and weather resistance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

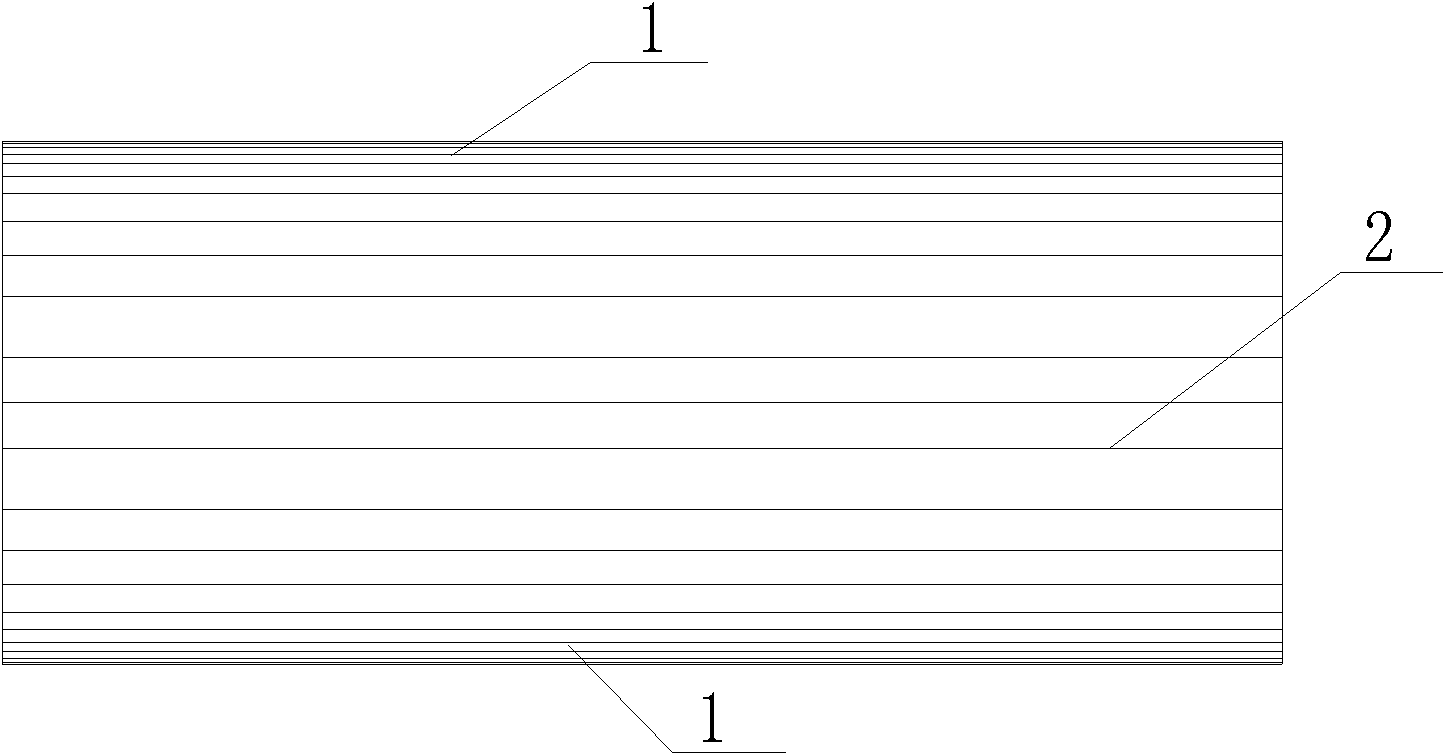

Image

Examples

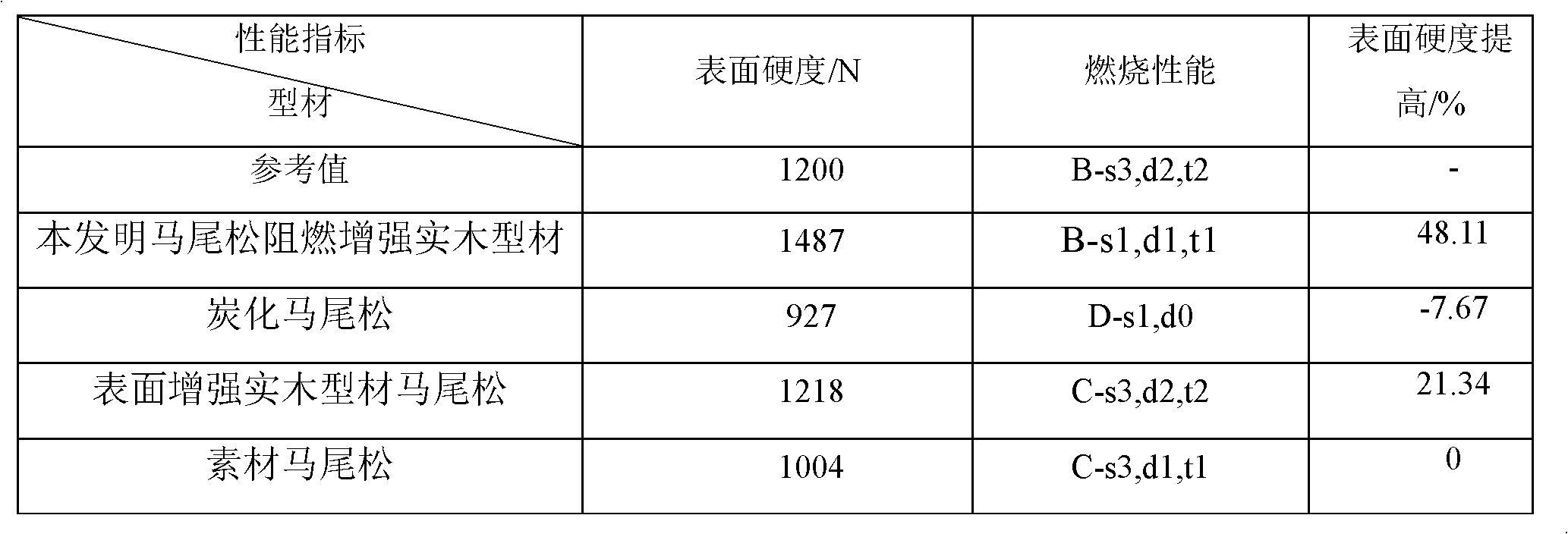

Embodiment 1

[0036] (1) Carbonization step: select masson pine sawn timber, and dry it with a moisture content of 12% according to a conventional drying method. Then stack the wood neatly and press 1t / m on the top of the wood pile 2 The standard pressurized steel plate frame pours concrete briquettes, and then puts them into wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 90°C, and the humidity is humidified to 80% relative humidity, keep for 4 hours, and then use the stepwise heating method according to Raise the temperature to 125°C at a rate of 20°C / h and keep it for 4 hours. At this time, the relative humidity is 100%. Then use a stepwise heating method to raise the temperature to 200°C at a rate of 15°C / h and keep it at the highest temperature for 4 hours. After the end, use the method of spraying atomized water to quickly cool down the wood until the temperature in the carbonization equipment is less than 120°C, stop the kiln to complete the ca...

Embodiment 2

[0048] (1) Carbonization step: select poplar sawn timber, and dry it with a moisture content of 5% according to a conventional drying method. Then stack the wood neatly and press 1t / m on the top of the wood pile 2 The standard pressurized steel frame pours concrete briquettes, and then puts them into the wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 80°C, and the humidity is humidified to 70% relative humidity, keep for 2 hours, and then adopt the stepwise heating method according to Raise the temperature to 135°C at a rate of 10°C / h and keep it for 2 hours. At this time, the relative humidity is 100%. Then use a stepwise heating method to raise the temperature to 175°C at a rate of 8°C / h and keep it at the highest temperature for 2 hours. After the end, use the method of spraying atomized water to quickly cool down the wood until the temperature in the carbonization equipment is less than 120°C, stop the kiln to complete the carboniza...

Embodiment 3

[0060] (1) Carbonization step: select the radiata pine sawn timber, and dry it with a moisture content of 8% according to a conventional drying method. Then stack the wood neatly and press 1t / m on the top of the wood pile 2 The standard pressurized steel plate frame pours concrete briquettes, and then puts them into wood carbonization equipment, heats up and humidifies rapidly, the temperature rises to 85°C, and the humidity is humidified to 75% relative humidity, keep for 3 hours, and then adopt the stepwise heating method according to Raise the temperature to 130°C at a rate of 15°C / h and keep it for 3 hours. At this time, the relative humidity is 100%. Then use a stepwise heating method to raise the temperature to 190°C at a rate of 12°C / h and keep it at the highest temperature for 3 hours. After the end, use the method of spraying atomized water to quickly cool down the wood until the temperature in the carbonization equipment is less than 110°C, stop the kiln to complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com