Preparation method of ultralarge high-pore-density honeycomb ceramic mold

A technology of ultra-large size and honeycomb ceramics, which is applied in the field of making molds for ceramic production, and can solve problems such as not being able to meet needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

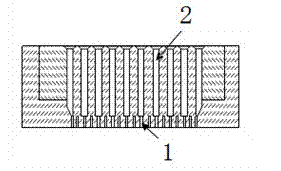

[0027] The manufactured product diameter is ?350mm, the grid wall thickness is 0.18mm, the hole density is 300 mesh, and the extrusion pressure is greater than 15Mpa honeycomb ceramic mold.

[0028] (1) Two pieces of circular SKD11 mold steel are selected, processed by lathe and grinder respectively, into a mold blank with a thickness of ?480mm and a thickness of 20mm, and a blank of a mud deflector with a thickness of ?480mm and 18mm.

[0029] (2) Overlay the above two blanks together, tap two points on the diameter line of the blank 5mm away from the edge of the blank, and then use a screw to fix the two blanks together.

[0030] (3) Fix the two fixed blanks on the precision drilling machine according to the upward direction of the mud guide plate, take the center of the blank circle as the positioning point, and follow the mold design plan (product diameter 350mm, 300 mesh, grid wall thickness 0.18 mm, product shrinkage rate 7%), program the drilling machine for the first d...

Embodiment 2

[0039] Manufacture ?450mm, cell wall thickness 0.22mm, hole density 200 mesh, extrusion pressure greater than 15Mpa honeycomb ceramic mold.

[0040] (1) Select two round SKD61 mold steels, and process them into a mold blank with a thickness of 600mm and a thickness of 22mm and a blank of a mud guide plate with a thickness of ?

[0041] (2) Overlay the above two blanks together, tap two points on the diameter line of the blank 5mm away from the edge of the blank, and then use a screw to fix the two blanks together.

[0042] (3) Fix the two fixed blanks on the precision drilling machine according to the upward direction of the mud guide plate, take the center of the blank circle as the positioning point, and follow the mold design plan (product diameter 450mm, 200 mesh, grid wall thickness 0.22 mm, product shrinkage rate 5%), program the drilling machine for the first drilling: drilling range: within a circle with a diameter of 500mm in the center of the blank, hole arrangement:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com