Comb honey box

A honeycomb box and box body technology, applied in the field of beekeeping, can solve problems such as reducing production efficiency and increasing work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

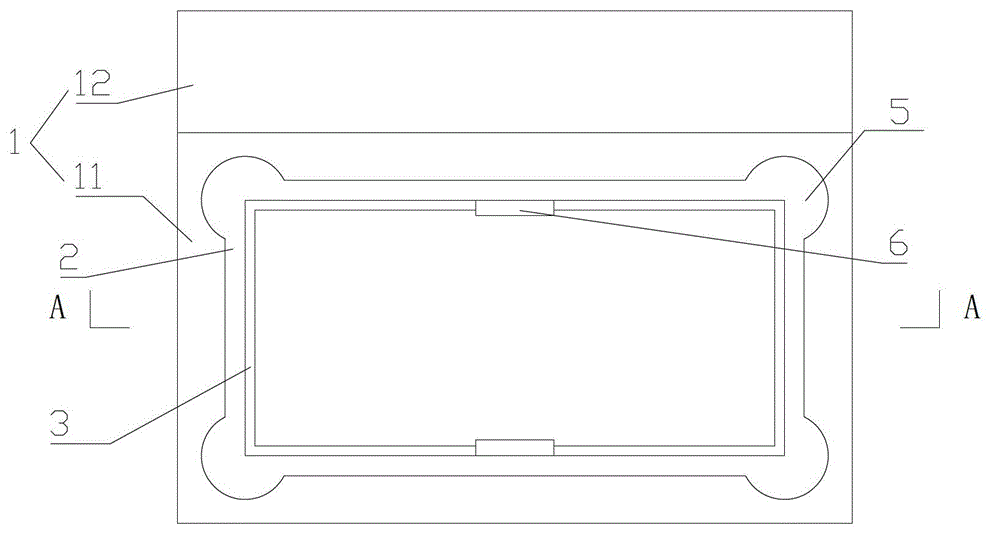

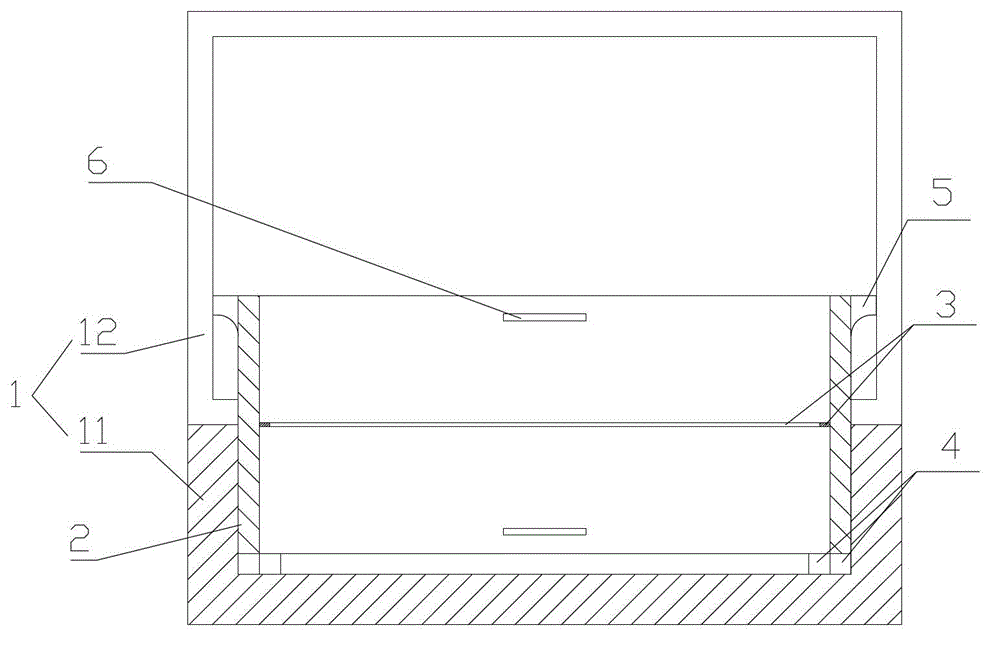

[0018] Such as figure 1 and figure 2 As shown, a honeycomb box includes an outer box 1 made of a box body 11 and a lid 12 and a honeycomb frame 2 placed in the outer box 1. The inner wall of the honeycomb frame 1 is provided with a beeswax ring along the circumference to facilitate rolling. The flange 3 of the honeycomb foundation, the lower end surface of the honeycomb frame 1 is provided with a downwardly protruding support foot 4, and the inner wall of the honeycomb frame 2 is provided with a limiting convex strip 6, and the limiting convex strip 6 is distributed on the On the upper and lower sides of the flange 3, the box cover 12 is transferred to the box body 11, and the box body 11 and the box cover 12 are provided with buckles and hooks that cooperate with each other. In order to speed up the building of the honeycomb, the flange 3 is arranged in the middle of the honeycomb frame 1 . The outer edge of the upper end surface of the honeycomb frame 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com