Control method for variable excitation synchronous motor MTPA based on multi-line fitting

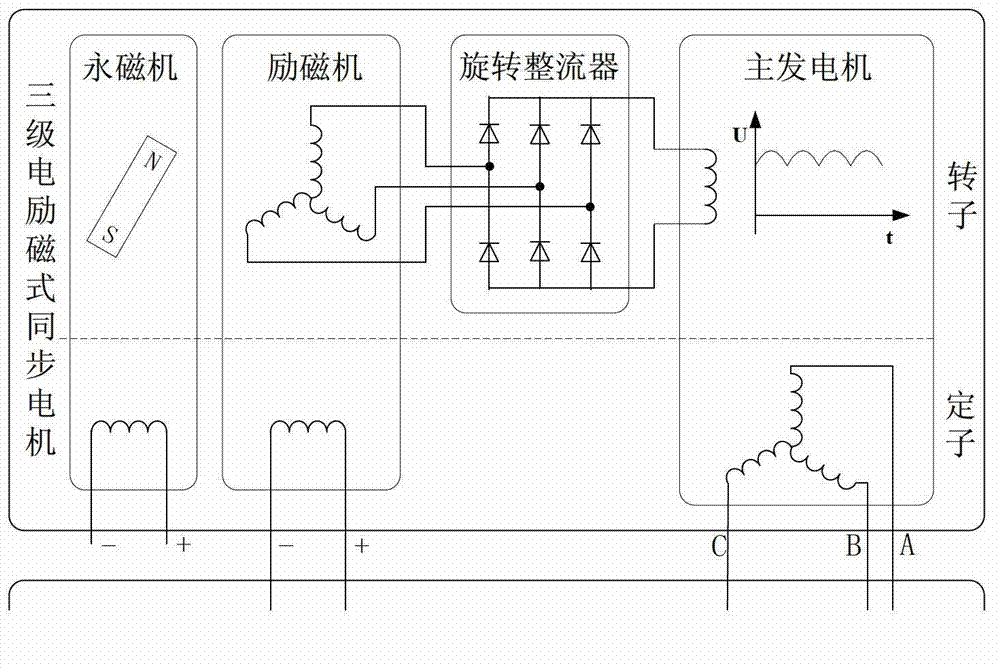

A technology of synchronous motor and control method, which is applied in the direction of synchronous generator control, motor generator control, electronic commutation motor control, etc. It can solve the problems of difficult determination of accurate analytical formula, low output voltage of exciter, and change of excitation current. Achieve the effect of simple and effective method, good fitting degree and small memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

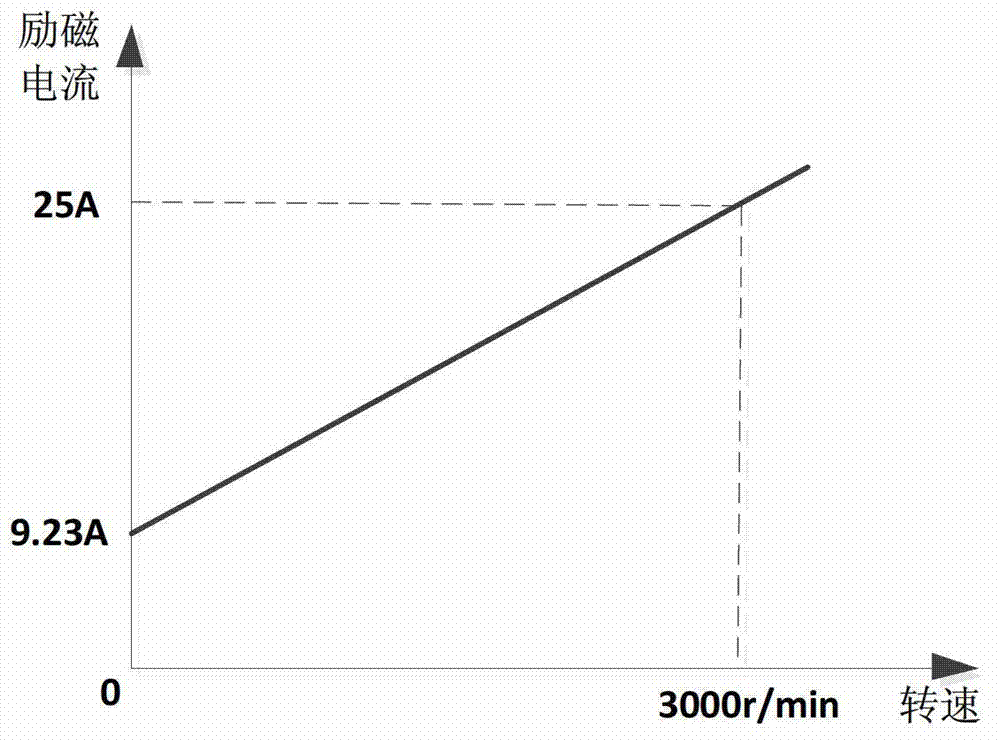

[0035] In order to verify the method of the present invention, Matlab2008b-Simulink6.0 is used for simulation verification. The parameters of the electric excitation synchronous motor in the simulation are: number of pole pairs n P =3; Stator winding resistance R s =10.3mΩ; direct axis inductance L d =0.63mH; quadrature axis inductance L q =0.31mH; mutual inductance L m =6mH; Given speed n N = 3000 (r / min). The curve of excitation current changing with speed is as follows: image 3 shown. The specific simulation conditions are set as follows: the starting load is 15Nm, and then gradually increases to 45Nm. When the motor torque reaches 2200 (r / min), the load gradually decreases and stabilizes when the load is 6Nm.

[0036] The concrete steps that embodiment comprises are as follows:

[0037] Step 1: Excitation flux linkage Ψ of synchronous motor f The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com