Wiring method for realizing direct-current deicing of ground wire of converter station

A technology of DC ice melting and wiring method, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of rising output voltage of ice melting device, reduced lightning protection effect of ground wire, and rising cost of ice melting device, etc. Achieve the effect of flexible ground wire DC ice melting method, improved ice melting effect, and reduced cost of full insulation transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

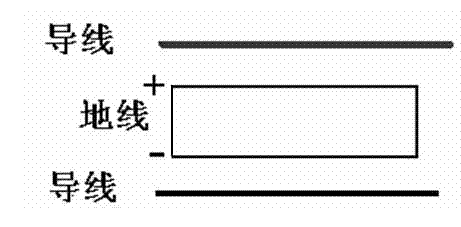

[0058] Example 1: figure 2 , which shows a schematic diagram of parallel wiring in which the ground wire is divided into one segment. When n is 1, it is only necessary to short-circuit a number of ground wires that are basically aligned with each other in the ground wire segment at the beginning and end, and connect wire 1 to the short-circuit point at the beginning of the ground wire at the beginning, and connect wire 2 to the beginning of the ground wire at the end. The ends of the ground wires are connected with a short-circuit point. The wires "+" and "-" marked in the figure are the output access points of the DC ice melting device. In the case of not considering the wire resistance (the wire resistance is negligible relative to the ground wire resistance), and there are two ground wires in the ground wire segment, it is assumed that the resistance of each ground wire is r, and the equivalent resistance is r / 2. When melting ice, the current on each branch of the gr...

Embodiment 2

[0059] Example 2: image 3 The line structure when n is 2 is listed. When n is 2, the wiring implementation process is to divide the ground wire into two sections at 1 / 2 (insulation between the two sections), and short-circuit the ground wires at the beginning and end of each ground wire segment that are parallel to each other and basically aligned at both ends. , and connect the beginning of each ground segment to wire 1, and connect the end of each ground segment to wire 2. The wires marked with "+" and "-" in the figure are the output access points of the ice melting device. The resistance of a single ground wire in each ground wire segment is r / 2, and the definition of r is the same as that in Embodiment 1, which is the equivalent resistance of a whole single ground wire. In the case of not considering the wire resistance and there are two ground wires in the ground wire segment, the equivalent resistance of the ground wire after being segmented and connected in parallel...

Embodiment 3

[0060] Embodiment 3: as Figure 4 , when n is 4, the wiring implementation process is to divide the ground wire into 4 segments (each segment is insulated), short-circuit a number of ground wires in each ground wire segment that are basically aligned with each other at both ends, and connect each The beginning of each ground segment is connected to wire 1 and will be connected to wire 2 at the end of each ground segment. The wires marked with "+" and "-" in the figure are the output access points of the ice melting device. The resistance of a single ground wire in each ground wire segment is r / 4, and the definition of r is the same as that in Embodiment 1. When the wire resistance is not considered and there are two ground wires in the ground wire segment, the ground wire is divided into It is 4 sections and the equivalent resistance r / 32 of parallel connection is 1 / 16 of embodiment 1. The output current of the DC ice-melting device is 8i, and the output voltage is u=ir / 4. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com