Cable tensile resistance device based on two-dimension fuzzy control

A fuzzy control and stretching device technology, applied in the field of control, can solve the problems of non-real-time automatic adjustment and high cost, and achieve the effects of reducing the power consumption of the reel drive motor, prolonging the service life, and simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

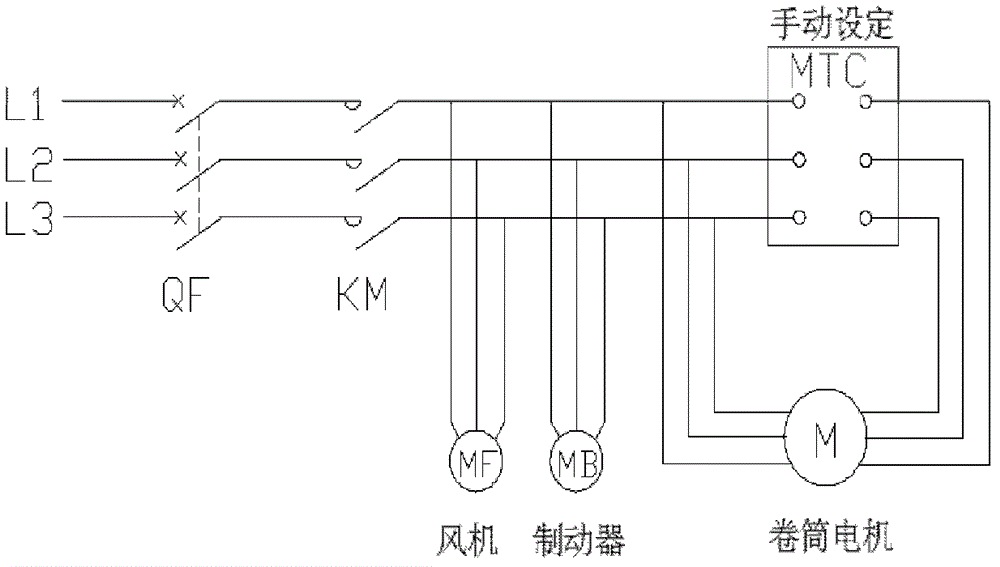

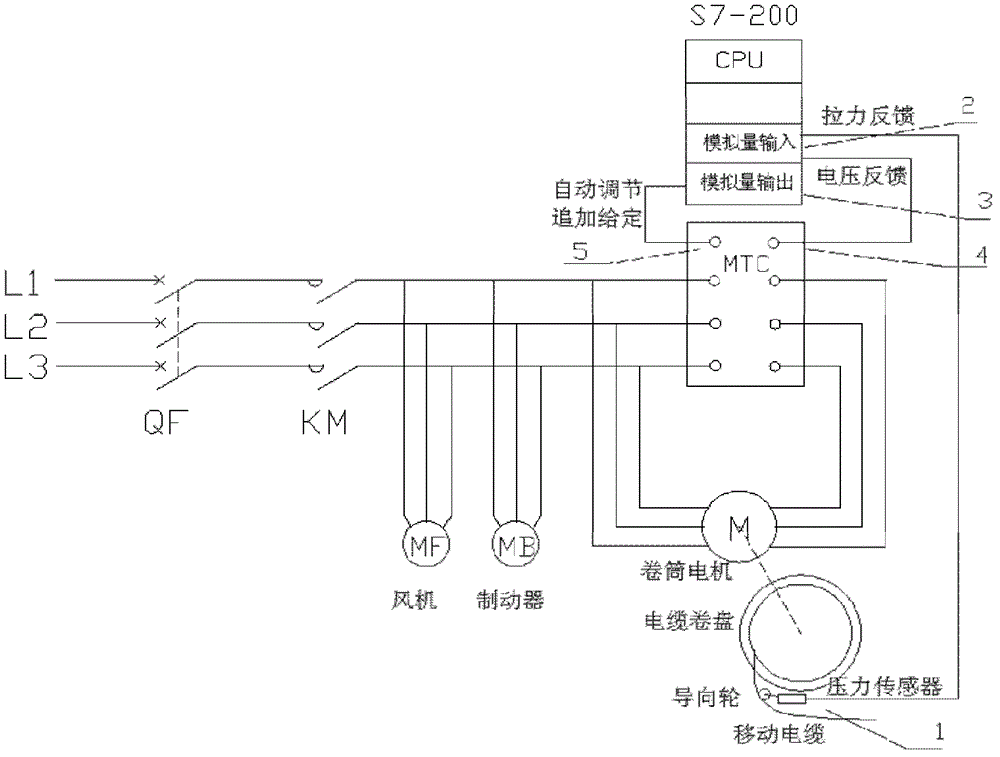

Method used

Image

Examples

Embodiment

[0062] The control device has been installed, debugged and operated according to the site conditions and requirements.

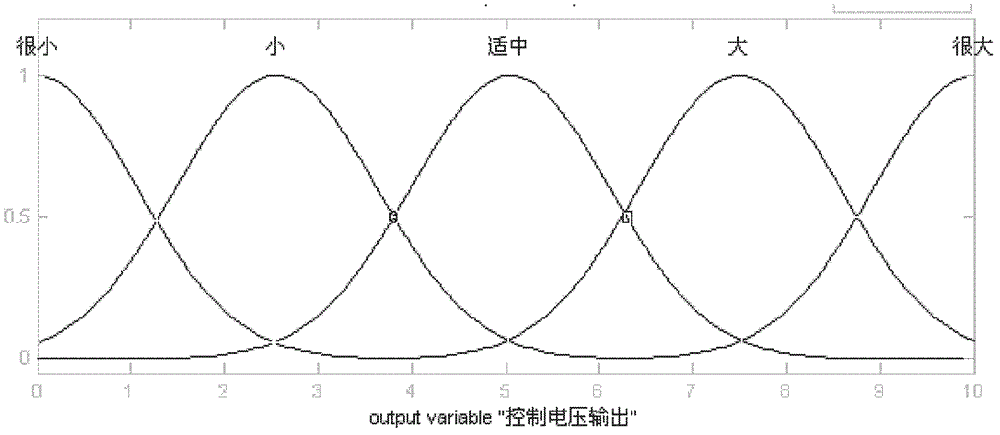

[0063] Step 1: Determine the upper and lower limits of the working voltage of the cable reel in the data input module according to the needs of the site. The site fully guarantees that the voltage that can be driven normally when the cable reel is full is VD=210V, and that the reel can be driven when the reel is empty. The voltage is V0=160V. The voltage within the working range is divided into 5 grades: 160V~170V is "very small", 170V~180V is "small", 180V~190V is "moderate", 190V~200V is "big", 200V~210V For "very large".

[0064] Step 2: Divide the actual cable pull force feedback information and voltage regulator output voltage feedback information into membership degrees, and the results are divided into "very small", "small", "moderate", "large", and "very large" on average files.

[0065] The feedback voltage of the tension sensor is a standard sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com