Real-time visual detection and identification method for high speed rail surface defect

A recognition method, real-time vision technology, applied in character and pattern recognition, optical test flaws/defects, instruments, etc., can solve the complex shape of rail surface defects, defect speed requirements, target detection and recognition methods can not meet the online high speed at the same time and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

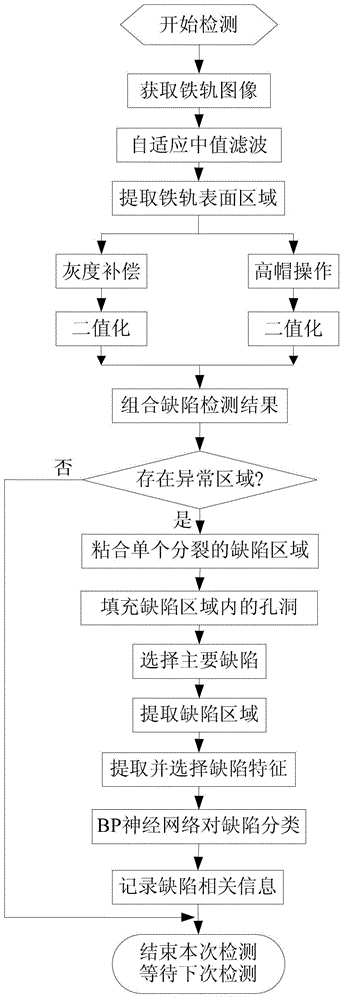

[0094] Such as figure 1 Shown, the real-time visual detection and identification method of high-speed rail surface defect of the present invention, its flow process is:

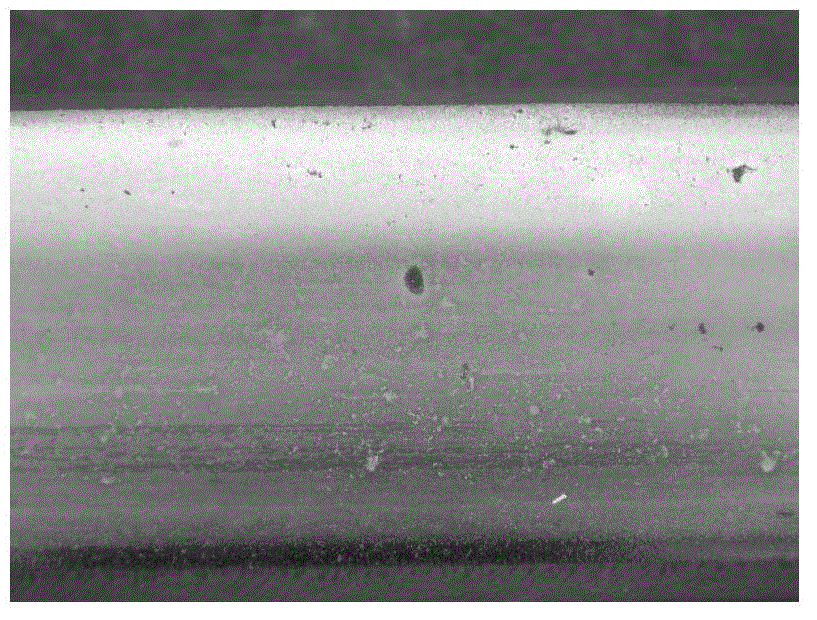

[0095] 1. Image acquisition: The detection system acquires the rail line image while the train is running at high speed on the rail track, and stitches N frames of line images into a panoramic image.

[0096] In this embodiment, the detection system runs at high speed along with the detection train on the rails, and the photoelectric encoder installed on the train wheel sends a pulse signal to trigger the line array camera to collect line images, and splicing 1536 frames of line images into a rail panoramic image. This trigger shooting method of the camera can make the acquisition frequency of the rail image consistent with the speed of the detected train, which wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com