Measuring device of high-temperature superconductive suspension tiny force

A measuring device, high-temperature superconducting technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve thruster tests that are not suitable for large masses, performance limitations of optical fiber tensile strength, and increased friction And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

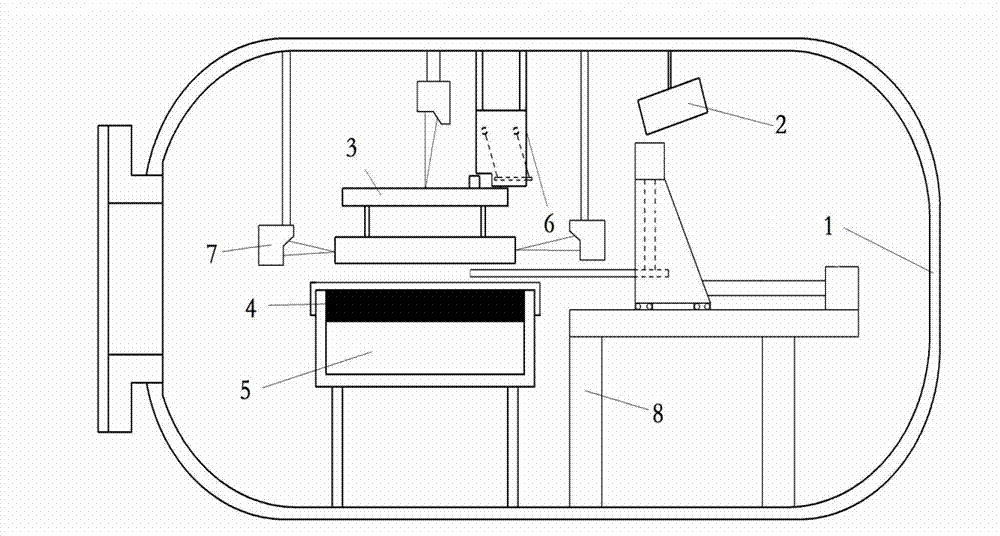

[0041] The invention is a high-temperature superconducting suspension micro-force measuring device, such as figure 1 As shown, it includes a vacuum chamber 1, a high-speed camera 2, a permanent magnet platform 3, a superconductor platform 4, a cryogenic system 5, a calibration striker structure 6, a CCD laser speedometer 7 and a floating mechanism 8.

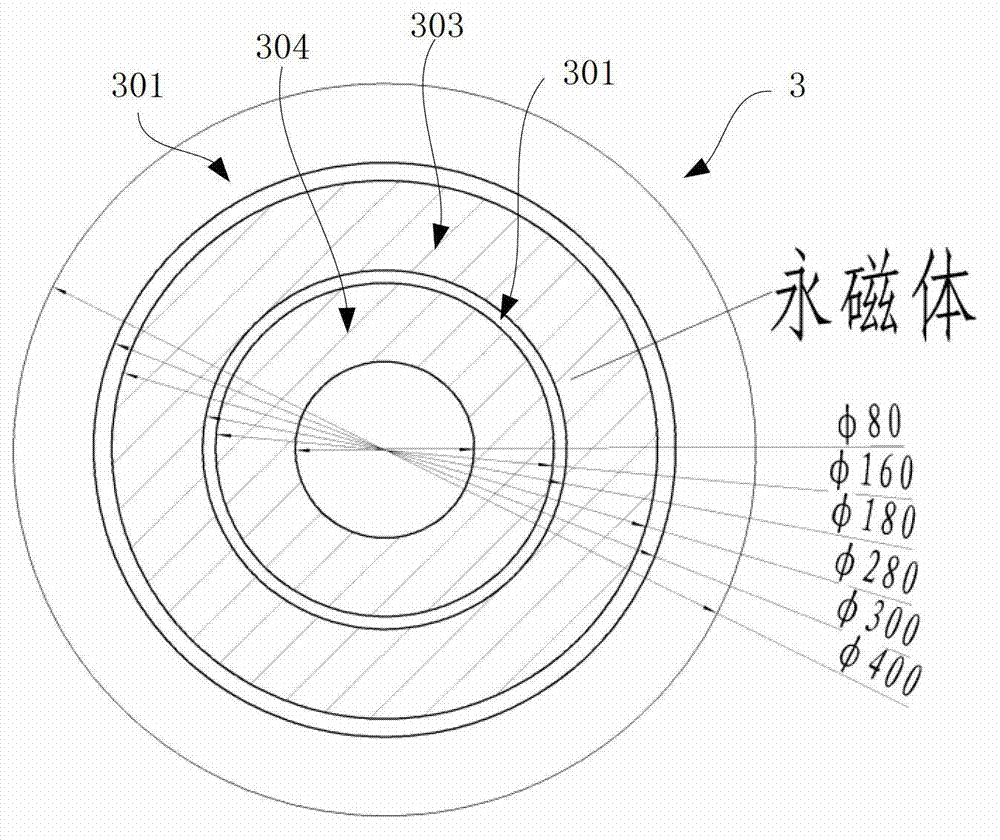

[0042]The cryogenic system 5 is fixed at the bottom of the vacuum chamber 1 , the superconductor platform 4 is located at the upper end of the cryogenic system 5 , and the cryogenic system 5 implements cryogenic cooling of the superconductor platform 4 . An epoxy resin cover with a thickness of 3 mm is also arranged above the superconductor platform 4 to produce a pressing effect on the upper surface of the superconductor.

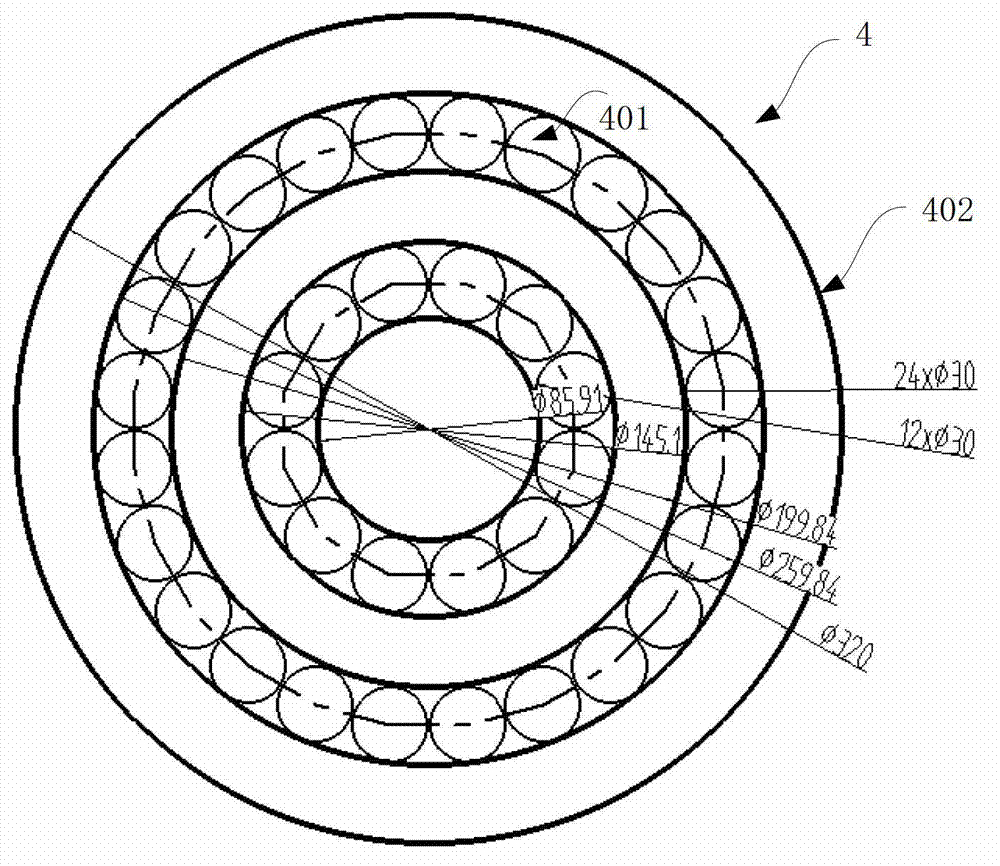

[0043] The superconductor platform 4 includes a superconductor 401 and a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com