Bearing type transmission wheel

A transmission wheel and bearing technology, applied in the field of meshing transmission, can solve the problems of heating noise and poor stability, need to be repaired, and prone to broken teeth, etc., and achieve the effects of eliminating relative friction, reducing manufacturing costs and facilitating maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Do further description below in conjunction with accompanying drawing:

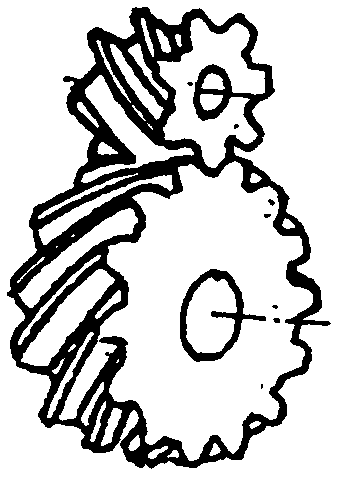

[0019] refer to Figure 6 , the left blade type transmission wheel and the right runner type transmission wheel are in operation, the runner 1 and the blade 2 are active and the other is passive. When they are close to each other, one is left-handed and the other is right-handed. Downward, wherein the runner 1 that abuts against the blade rotates to rotate clockwise while following the transmission wheel counterclockwise.

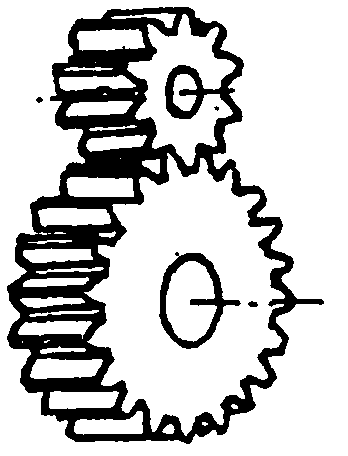

[0020] refer to Figure 7 , The runner type transmission wheel is installed in the inside of the arc-shaped fork type transmission wheel, one small and one large are internal meshing transmission, the large one is active and the small one is driven and is speed-up, otherwise it is deceleration.

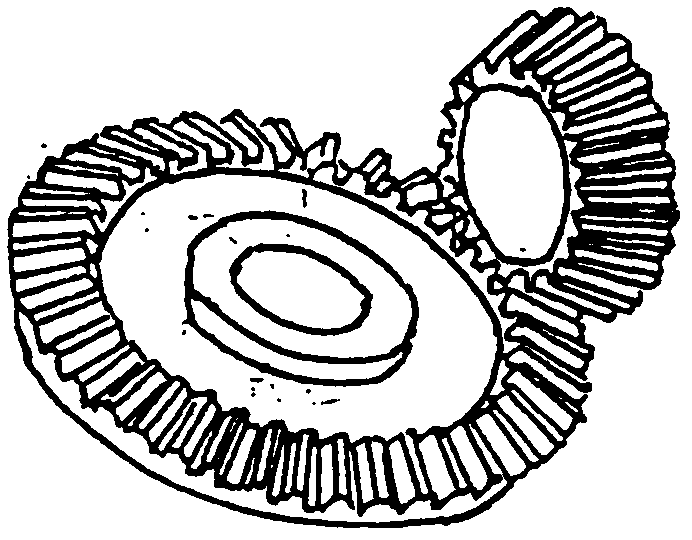

[0021] refer to Figure 8 , a number of runners 1 and a number of arc-shaped forks 3 are respectively installed on the columns 4 around the rim of each transmission wheel, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com