Hanging cable guiding device and method

A technology of guiding device and steel strand, applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of large construction quantity, manual switching, labor cost, etc., and achieve the effect of fast construction speed and high turnover times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical content of the present invention clearer, it will be further elaborated in conjunction with the drawings and embodiments, and the structure of the related devices can be realized by those skilled in the art.

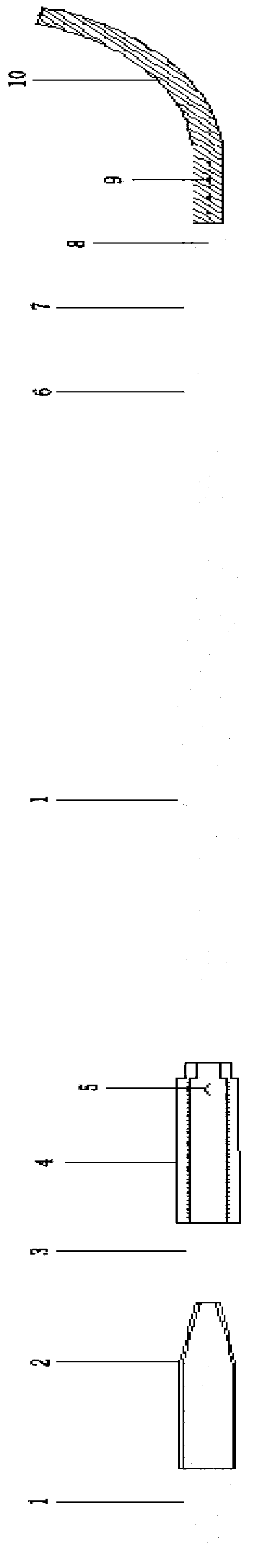

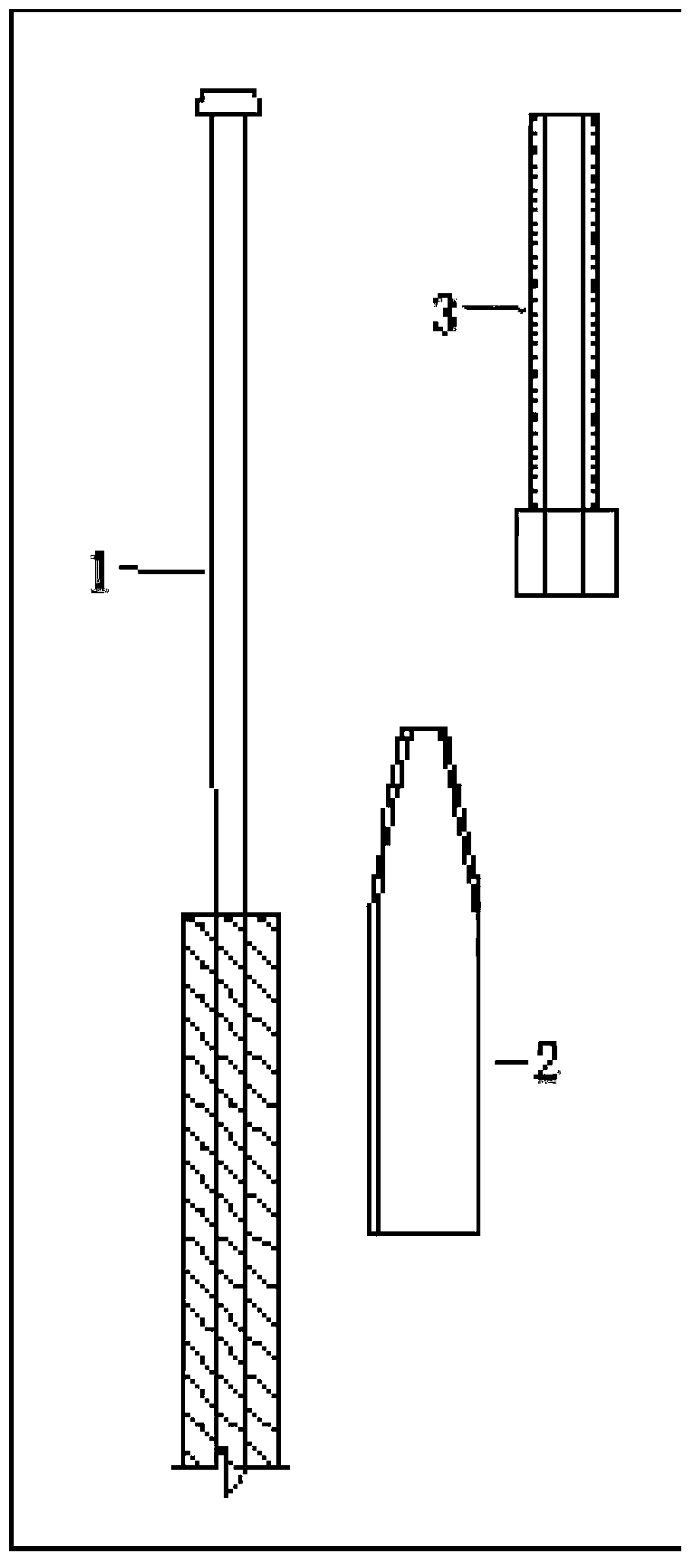

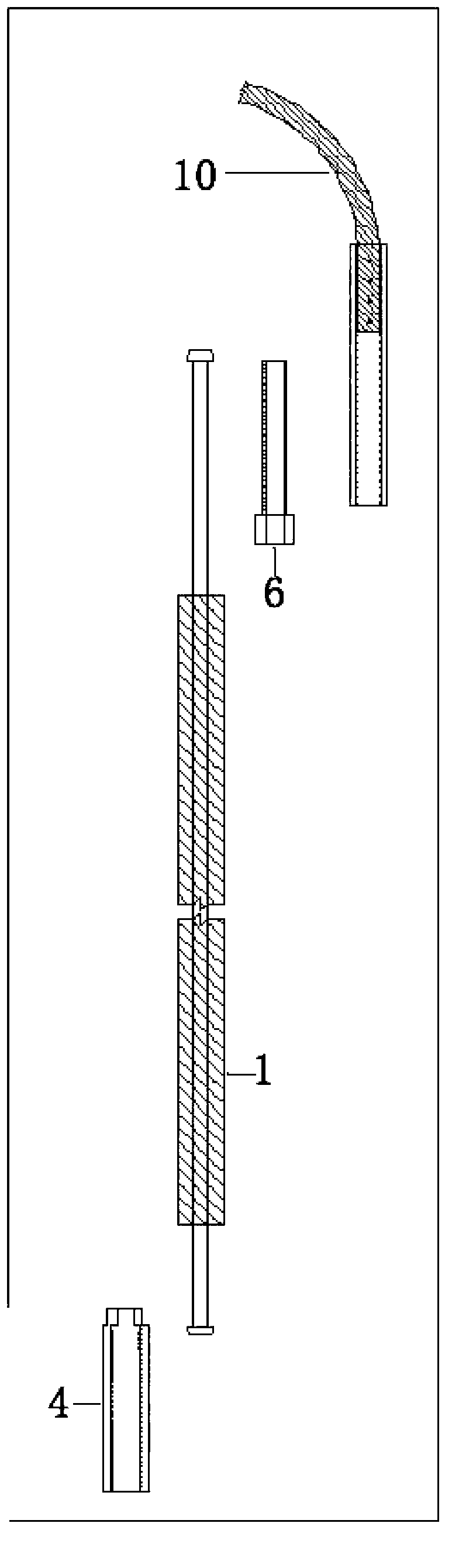

[0029] The present invention makes a structural improvement on the basis of the existing cable guide device, and the structure of the guide device obtained is as follows: figure 1 As shown, it includes threaded sleeves, steel ropes, high-strength bolts, steel wire ropes and high-strength screws. The steel ropes are 7-wire steel strands, which are characterized in that 1 wire Stranded wire, 1 steel strand at the left end is inserted into the first threaded sleeve 4, the end of the 1 steel strand at the left end is provided with a first pier head 5, the 1 steel strand at the right end passes through the second high-strength bolt 6, and the 1 steel strand at the right end passes through the second high-strength bolt 6. The end of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com