Novel aluminum refining agent, and preparation method thereof

A refining agent and a new type of technology, applied in the field of metallurgy, to achieve the effect of reducing production costs and avoiding emissions

Active Publication Date: 2013-01-02

LIAOCHENG XINYUAN GRP CO LTD

View PDF5 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to better solve the technical problem of aluminum ash utilization, the present invention provides an aluminum refining agent that does not contain NaCl, so that the addition of refined aluminum ash to the electrolytic cell will not affect the operation of the electrolytic cell

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

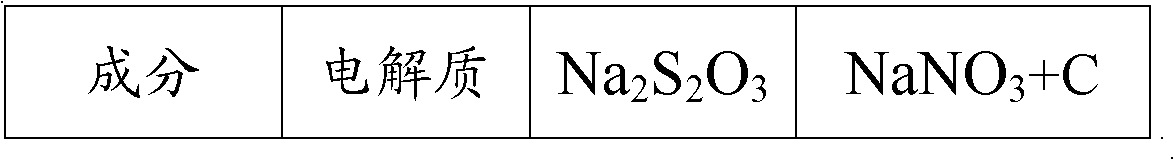

[0027] Element

Embodiment 2

[0029] Element

[0030]

Embodiment 4

[0033] Element

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel aluminum refining agent, and preparation method thereof, which is characterized in that the novel aluminum refining agent is composed of (by mass percentage) electrolyte 30-80%, heat generating agent 10-50% and degassing component 5-50%. Since the novel aluminum refining agent contains no sodium chloride component, addition of refined aluminum ash into an electrolytic bath can not cause effect on the running of the electrolytic bath, and by adopting excessive electrolyte as the main component for preparing the refining agent, the invention reduces the production cost, and facilities to environmental protection.

Description

technical field [0001] The invention belongs to the field of metallurgy and relates to a refining agent for aluminum refining, in particular to a novel aluminum refining agent for purifying aluminum melt. Background technique [0002] The liquid aluminum liquid produced by the aluminum electrolytic cell contains various impurities, mainly including alumina, carbon, aluminum carbide and residual electrolyte, among which alumina is the majority. These inclusions reduce the purity of aluminum liquid or aluminum alloy liquid, and affect the process performance, physical properties and mechanical properties of aluminum. Therefore, it is necessary to refine and purify aluminum liquid and aluminum alloy liquid to eliminate these gases and inclusions , Improve the quality of molten aluminum or aluminum alloy, and adding a refining agent to the molten aluminum or aluminum alloy for refining and purification is a commonly used measure. [0003] Judging from a large number of current ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B21/06C22B9/10C22C1/06

Inventor 张煜赵斌南唐剑敬叶灵

Owner LIAOCHENG XINYUAN GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com