Room temperature cured high-temperature resistant epoxy adhesive

An epoxy adhesive, room temperature curing technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of epoxy adhesive restrictions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

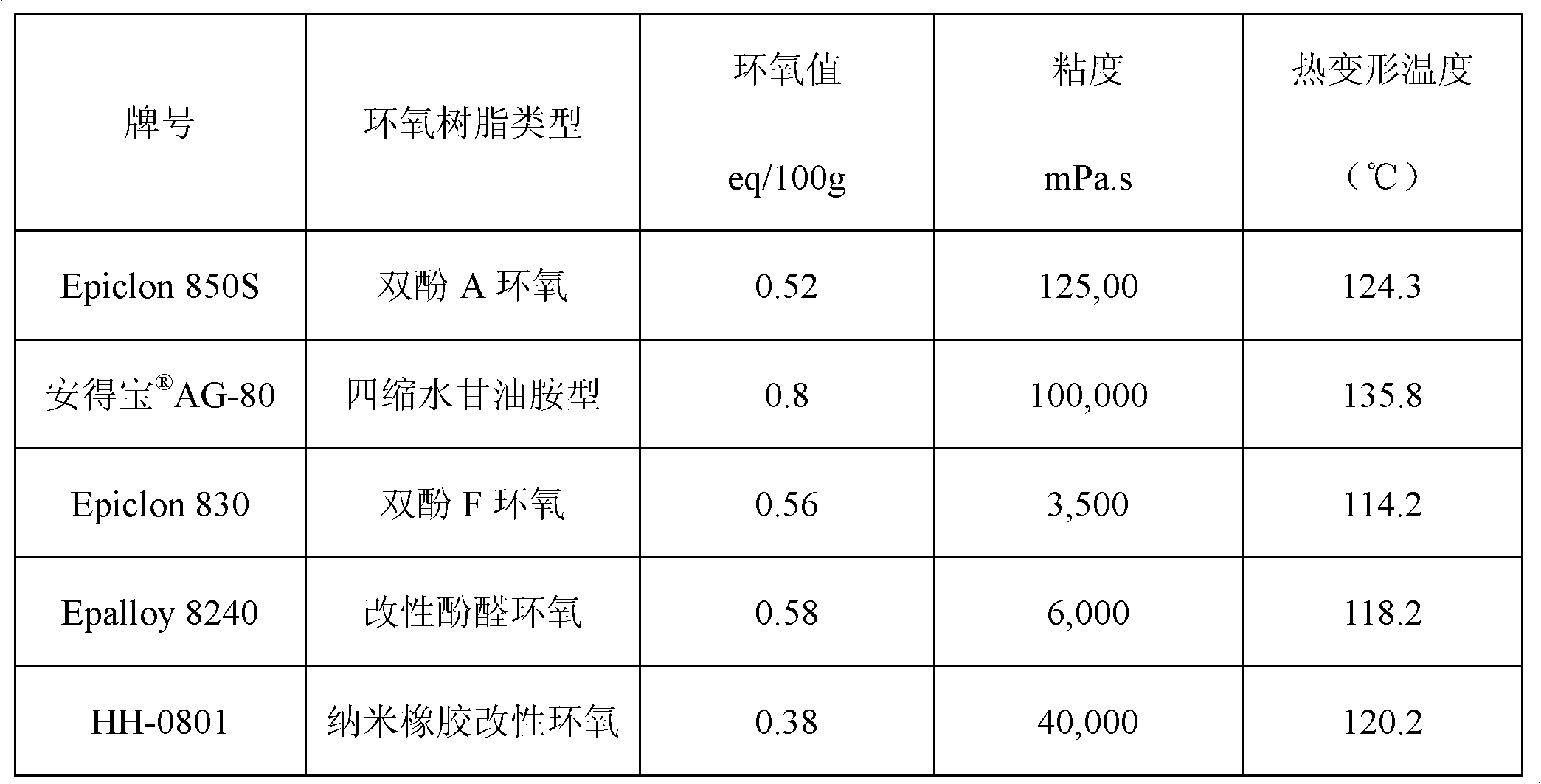

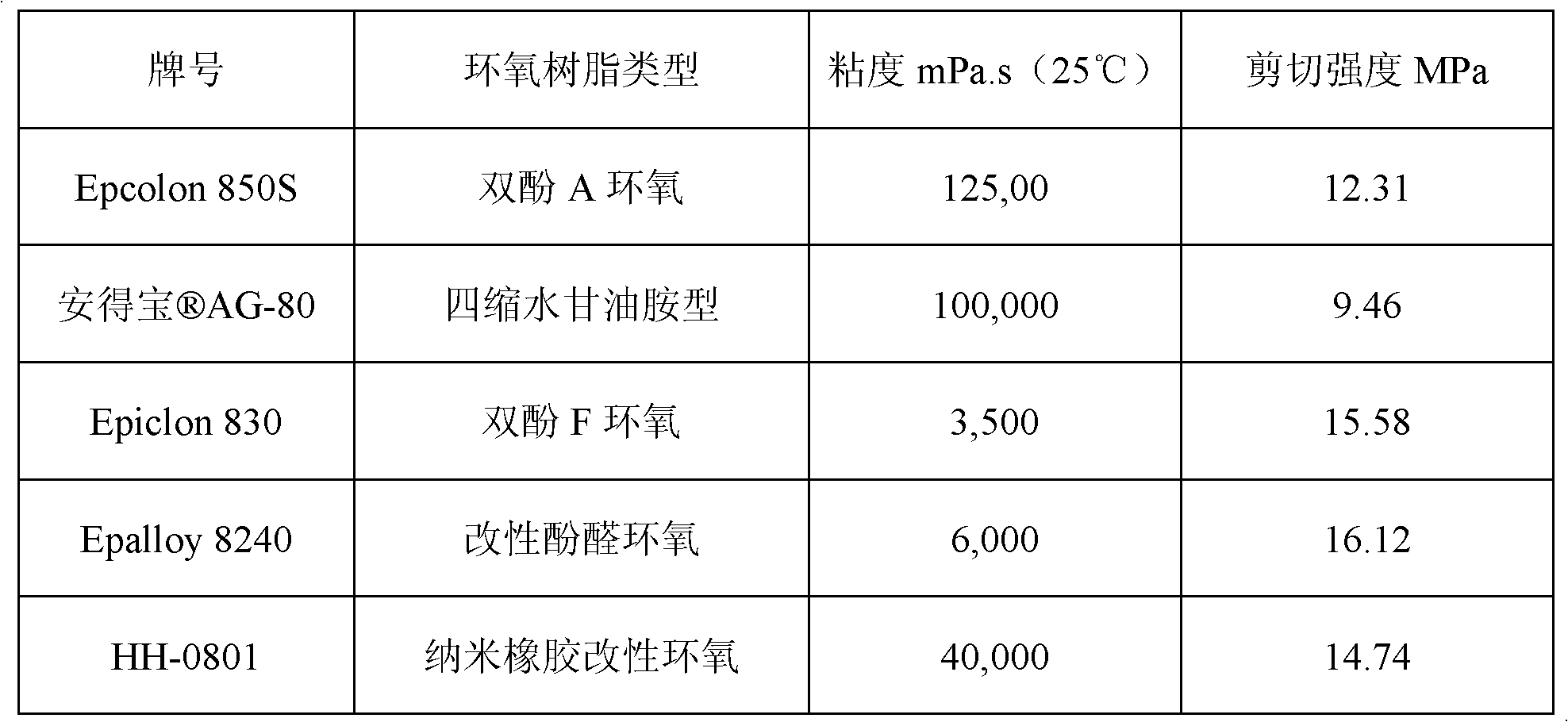

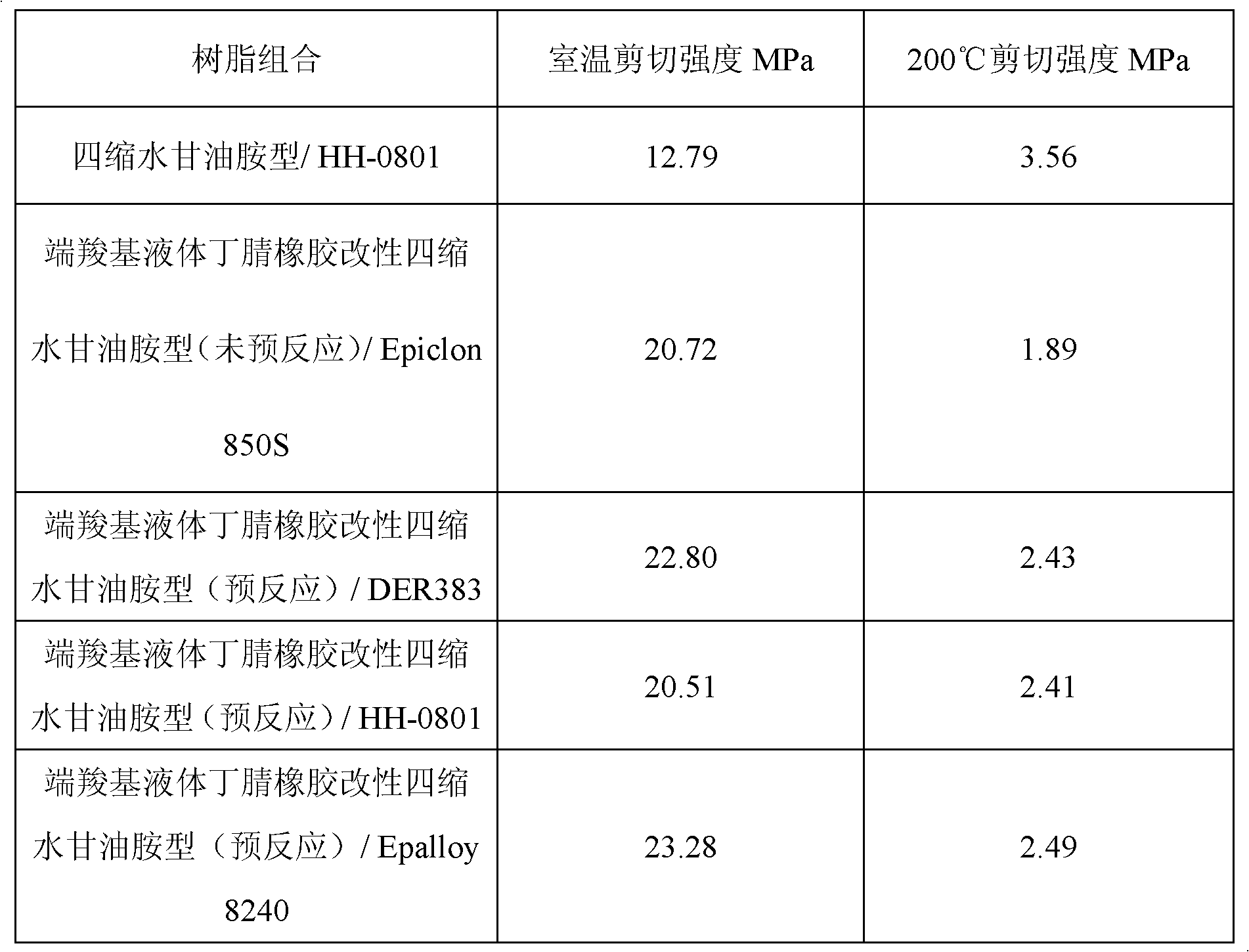

Method used

Image

Examples

Embodiment 1

[0050] Room temperature curing high temperature resistant epoxy adhesive is a two-component epoxy adhesive composed of a resin component and a curing agent component. When used, the weight ratio between the resin component and the curing agent component is 100:47.64; the resin component consists of 100 parts by weight of carboxyl-terminated liquid nitrile rubber modified Ande AG-80 and 25 parts by weight of bisphenol A diglycidyl ether compound; carboxyl-terminated liquid nitrile rubber modified Ande AG-80 is composed of 20 parts by weight of carboxyl-terminated nitrile rubber and 80 parts by weight of An Debao -80, using triphenylphosphine as a catalyst, pre-esterified at 125-135°C for 0.5-1 hour to form a block copolymer with epoxy group chain unit at both ends.

[0051] The curing agent component consists of 5.8 parts by weight of JH-5200 modified aromatic amine, 18 parts by weight of polyamide, 15.2 parts by weight of 4,4-diaminodiphenylmethane, 2.3 parts by weight of ...

Embodiment 2

[0058] Room temperature curing high temperature resistant epoxy adhesive is a two-component epoxy adhesive composed of a resin component and a curing agent component. The weight ratio between the resin component and the curing agent component is 100:50.2 when used;

[0059] Its resin component consists of 100 parts by weight of carboxyl-terminated liquid nitrile rubber modified tetraglycidylamine type epoxy resin and AG-70 and 25 parts by weight of bisphenol A diglycidyl ether are compounded; carboxyl-terminated liquid nitrile rubber modified tetraglycidylamine type epoxy resin is made of 20 parts by weight of carboxyl-terminated nitrile rubber and 80 parts by weight tetraglycidylamine polyfunctional epoxy resin AG-70 is prepared by using triphenylphosphine as a catalyst and pre-esterifying at 125-135°C for 0.5-1 hour to form a block copolymer with epoxy group chain units at both ends.

[0060] The curing agent component consists of 6.2 parts by weight of JH-5200 modified a...

Embodiment 3

[0064] Room temperature curing high temperature resistant epoxy adhesive is a two-component epoxy adhesive composed of resin component and curing agent component. The weight ratio between resin component and curing agent component is 100:52 when used.

[0065] Its resin component is compounded by 100 parts by weight of carboxyl-terminated liquid nitrile rubber modified tetraglycidylamine epoxy resin and 25 parts by weight of bisphenol A diglycidyl ether; carboxyl-terminated liquid nitrile rubber modified Tetraglycidylamine type epoxy resin is made of 20 parts by weight of carboxyl-terminated nitrile rubber, 40 parts by weight of AG-80, and 40 parts by weight of AG-70, using triphenylphosphine as a catalyst, pre-prepared at 125 to 135 ° C. After 0.5-1 hour of esterification reaction, a block copolymer with epoxy group chain unit at both ends is formed.

[0066] The curing agent component consists of 6.5 parts by weight of JH-5200 modified aromatic amine, 20 parts by weight of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com