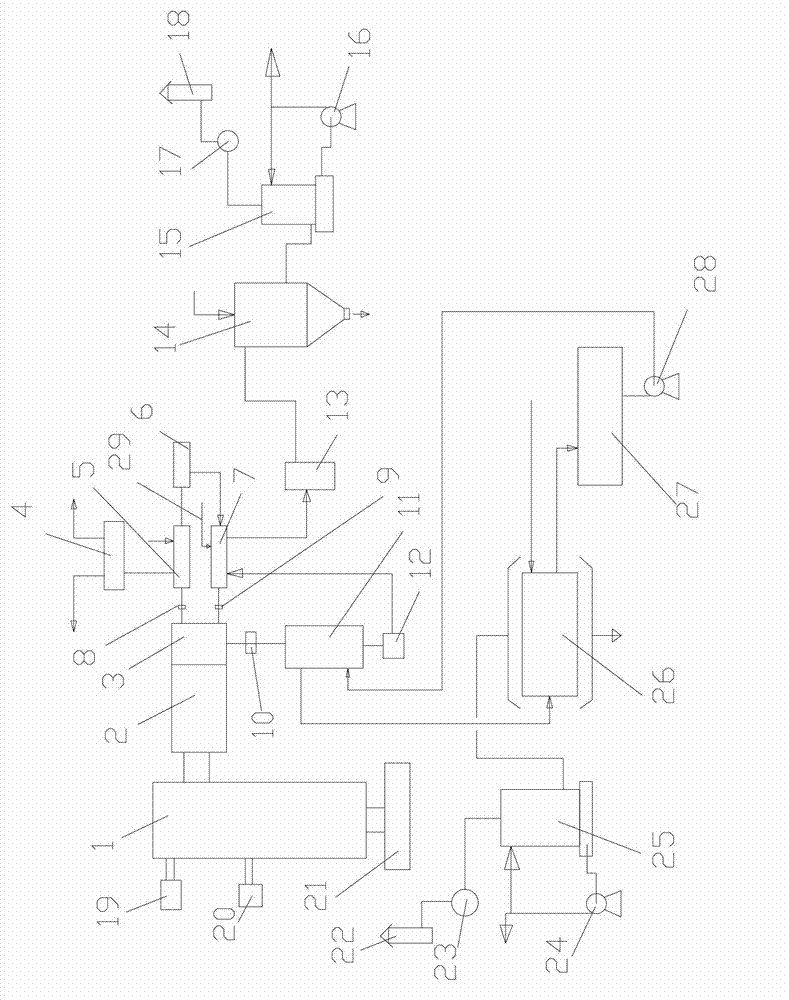

Method and device capable of simultaneously providing various clean heat sources to prepare polyaluminum chloride

A polyaluminum chloride, heat source technology, applied in aluminum chloride, aluminum halide, chemical industry and other directions, can solve the problems of low production energy consumption, large equipment investment, increase heat supply of steam boilers, etc., to achieve small heat loss and operation. The effect of low power and operating costs and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using 6000kcal / kg ordinary bituminous coal with a sulfur content of 2% as fuel, it is required to produce 3.5 tons of polyaluminium chloride (equivalent to solid products) per hour, including 2.0 tons of industrial-grade yellow products per hour (1.5 tons of which are drum-dried) Machine drying, another 0.5 tons are sold as liquid products, no need to dry) and drinking water grade light yellow polyaluminum chloride produces 1.5 tons per hour, drinking water grade products are dried with a spray dryer, industrial grade polyaluminum chloride liquid alumina The content is 10%, the basicity is 95%, the content of drinking water grade polyaluminum chloride liquid alumina is 14.0%, and the basicity is 75%. The total heat supply capacity of the combustor of the system is 5.3 million kcal / hour, the heat supply required for the drying of the drum dryer is 2 million kcal / hour, the heat supply required for the production of liquid polyaluminum chloride is 1 million kcal / hour, and t...

Embodiment 2

[0035]Using 4500kcal / kg bituminous coal with a sulfur content of 4% as fuel, it is required to produce 3.5 tons of polyaluminium chloride (equivalent to solid products) per hour, including 2.0 tons of industrial-grade yellow products per hour (1.5 tons of products are produced by drum dryers) Drying, another 0.5 tons are sold as liquid products, no drying is required) and high-purity grade white products are produced at 1.5 tons per hour, high-purity polyaluminum chloride is dried with a spray dryer, and the content of industrial-grade polyaluminum chloride liquid alumina is 10%, The basicity is 95%, the content of high-purity polyaluminum chloride liquid alumina is 18.0%, and the basicity is 48%. The total heat supply capacity of the combustion chamber of the system is 5.3 million kcal / hour, the actual heat consumption is 5.2 million kcal / hour, the heat supply required for drying by the drum dryer is 2 million kcal / hour, and the supply required for the production of liquid pol...

Embodiment 3

[0037] Using 5000kcal / kg bituminous coal with a sulfur content of 1% as fuel, it is required to produce 3.5 tons of polyaluminum chloride (equivalent to solid products) per hour, including 2.0 tons of industrial-grade light yellow products per hour (of which 1.5 tons of products are drum-dried machine drying, and another 0.5 tons are sold as liquid products without drying) and high-purity grade white products are produced at 1.5 tons per hour, high-purity polyaluminum chloride is dried with a spray dryer, and the content of industrial-grade polyaluminum chloride liquid alumina is 12% , the basicity is 89%, the content of high-purity polyaluminum chloride liquid alumina is 18.5%, and the basicity is 45%. The total heat supply capacity of the combustion chamber of the system is 5.3 million kcal / hour, the actual heat consumption is 5.1 million kcal / hour, the heat supply required for drying by the drum dryer is 1.95 million kcal / hour, and the supply required for the production of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com