Laminate compounding machine

A compound machine and laminating technology, applied in the field of laminating compound machines, can solve the problems that the extrusion device has no horizontal movement ability and up and down lifting ability, cannot cooperate with production well, and the transmission accuracy of the system is not high, so as to achieve flexible horizontal movement The effect of high power, simple structure, and flexible movement of the cutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

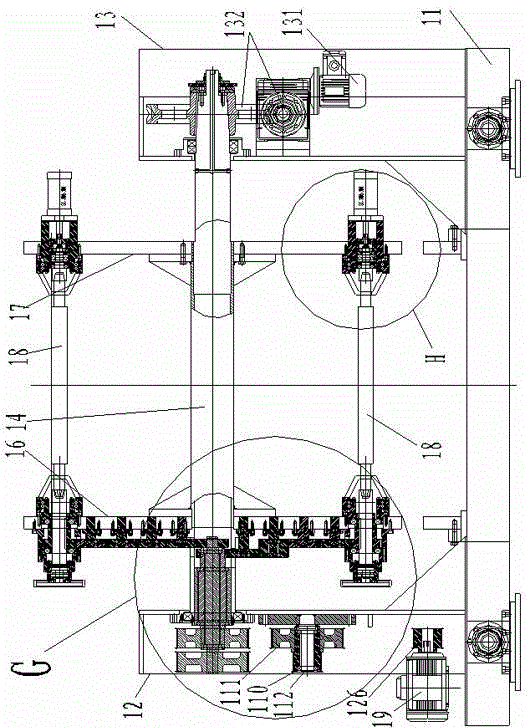

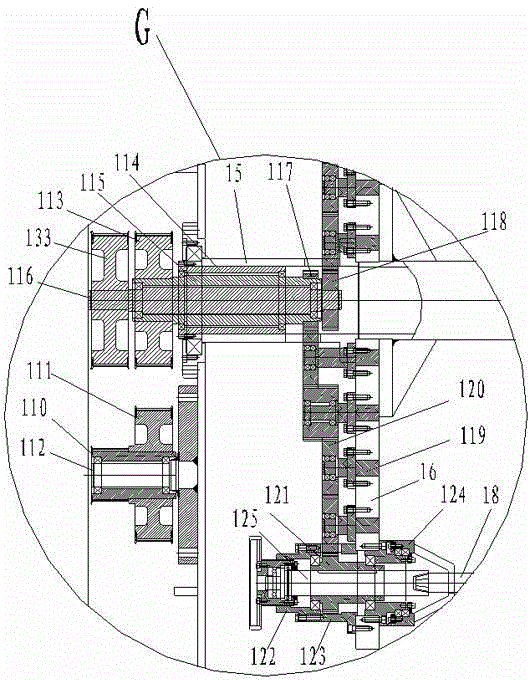

[0061] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

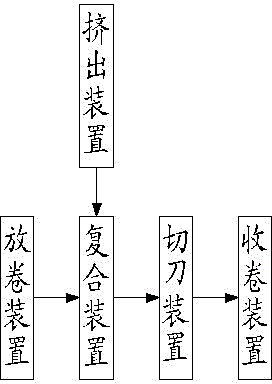

[0062] see Figure 1 to Figure 18 , the embodiments of the present invention include:

[0063] A laminating machine, comprising:

[0064] Unwinding device for unwinding the base material;

[0065] Extrusion device for providing coating material;

[0066] The compounding device is used for compounding the coating material and the base material;

[0067] Cutter device for trimming or slitting the coated substrate;

[0068] Rewinding device, used to rewind and store the finished base material after trimming or slitting;

[0069] The base material is successively transferred between the unwinding device, the compounding device, the cutter devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com