Long surface pedestal production line for two-way pre-tensioned pre-stressed concrete track slab

A technology of concrete and surface pedestal, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems such as mass production of two-way pre-tensioned concrete prefabricated components, rising production line costs, and a large number of tensioning systems that have not yet been discovered. The quality is not easy to guarantee, the production efficiency is low, and the effect of the tensioning system is saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below through exemplary embodiments. It should be pointed out that those skilled in the art can easily understand that the following examples are only illustrative, and are not meant to limit the present invention.

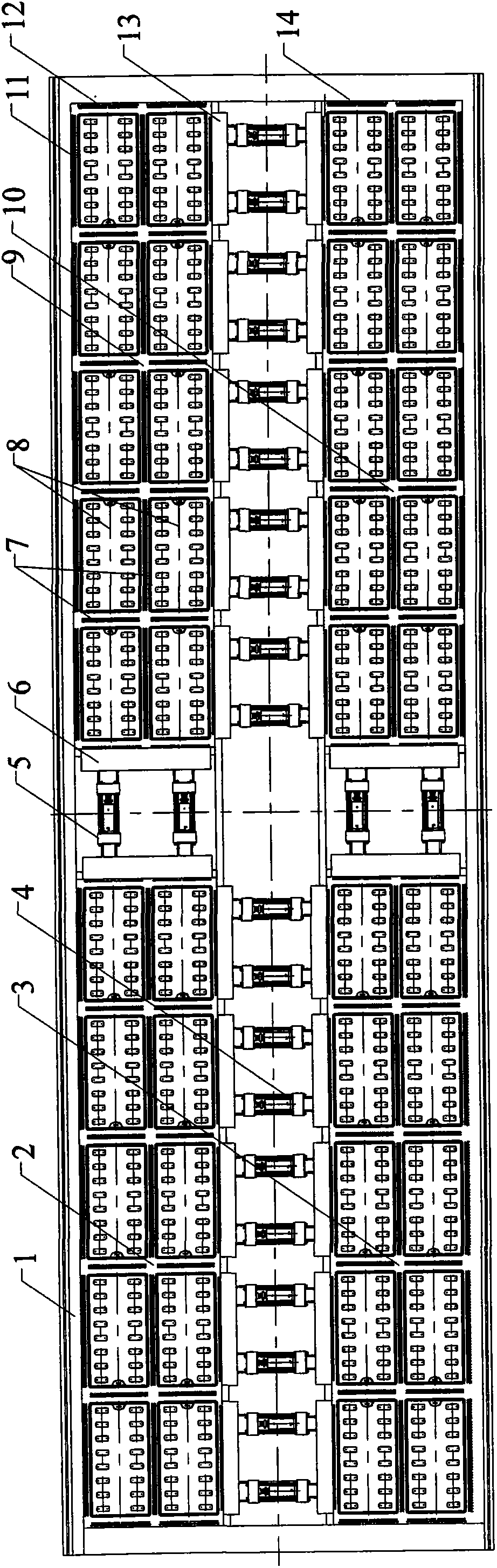

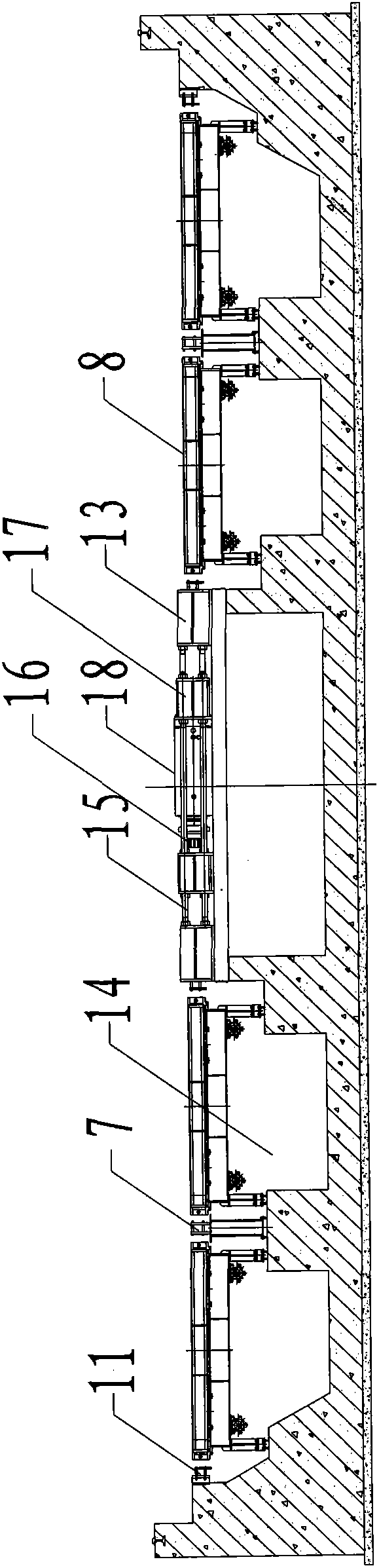

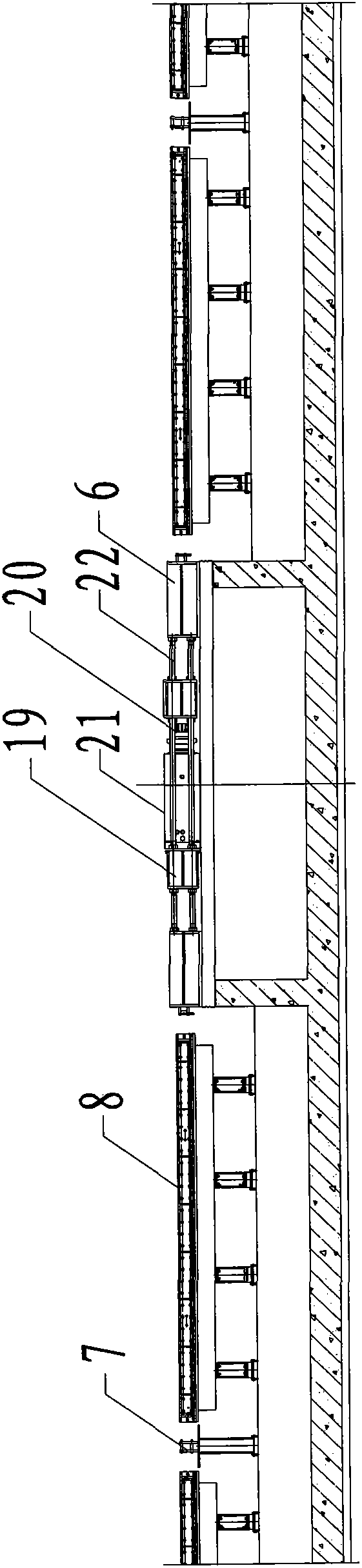

[0033] figure 1It shows a schematic plan layout of the production units of the production line of the bidirectional pretensioned prestressed concrete track slab long pedestal production line according to an exemplary embodiment of the present invention, and the production line may include one or more production units according to actual needs. As shown in the figure, each production unit includes four symmetrically arranged production areas 2, 3, 9, and 10. Steel models 8 for producing track slabs are set in each production area, and steel models 8 are set between the steel models to transmit the tensile force of steel bars. The steel wire connector 7, the four sides of each production area are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com