Special jig fixture for grinding non-standard optical fiber connectors

A technology of optical fiber connectors and molds, applied in the direction of the work carrier, etc., can solve the problems of easy deviation of the grinding angle, low product qualification rate, and low production efficiency, and achieve high production efficiency, high product qualification rate, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

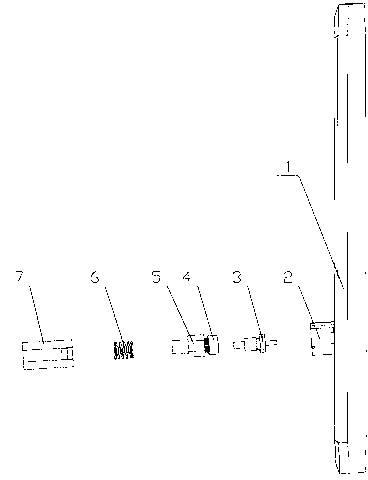

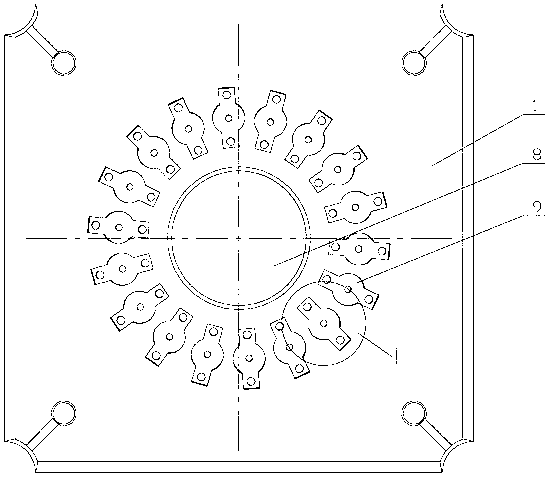

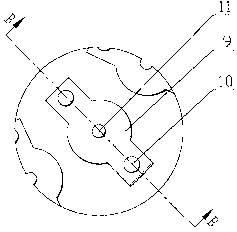

[0018] see Figure 1-9 , the present invention has chuck 1, and the center of chuck 1 is provided with mounting hole 8, particularly: on chuck 1, is designed with some mounting grooves 9 around mounting hole 8 periphery, the bottom surface of mounting groove 9 is inclined surface, and mounting groove The center of 9 is provided with a pin through hole 11, and there are two symmetrically arranged screw holes 10 located on both sides of the pin through 11 hole in the installation groove 9; a seat cover 2 is installed with a screw corresponding to each installation groove 9, so The side wall of the seat cover 2 is provided with two symmetrically arranged axial guide grooves 14, and the bottom of the two guide grooves is provided with a positioning hook groove 15 arranged to rotate in the same direction. The bottom of the seat cover 2 is provided with two symmetrically arranged installation Ears 12, screw holes 13 are opened on each mounting ear 12; a positioning sleeve 7 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com