Tank fabricating and welding method

A welding method and tank technology, applied in the field of steel plate welding, can solve the problems of low construction quality, waste of construction materials, deformation of tank wall panels, etc., and achieve the effects of safe and reliable engineering quality, reduction of construction costs, and control of welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

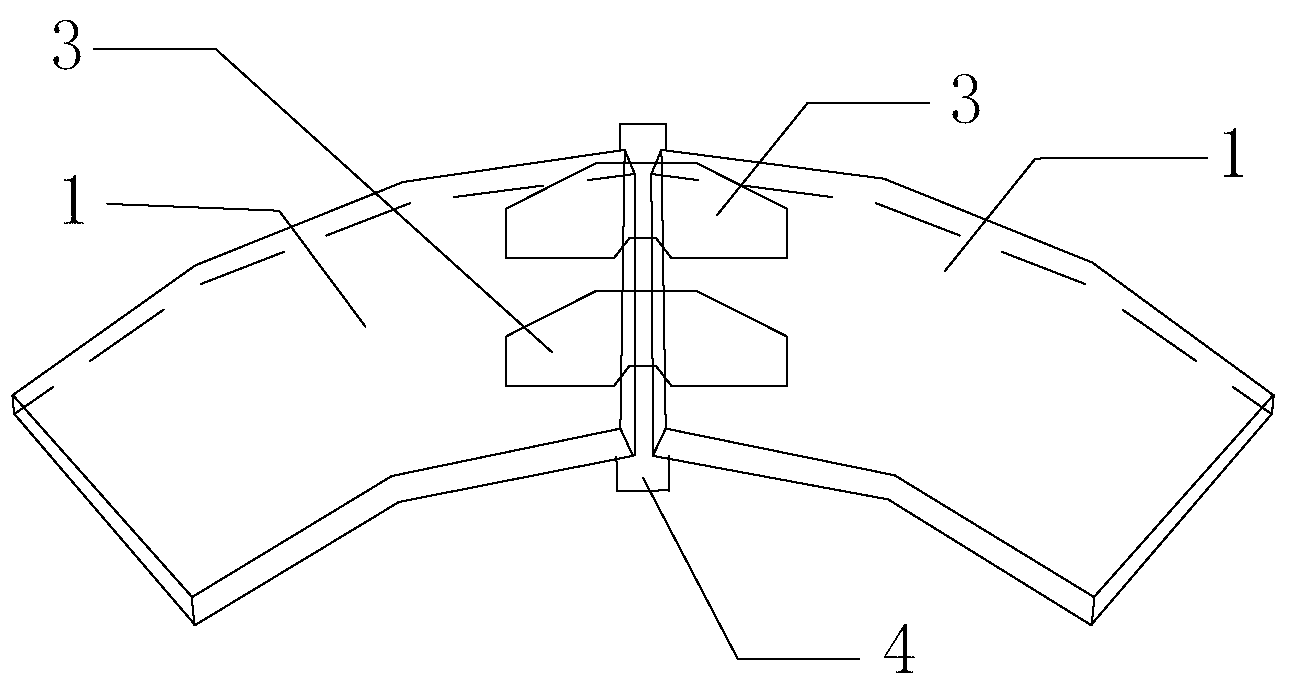

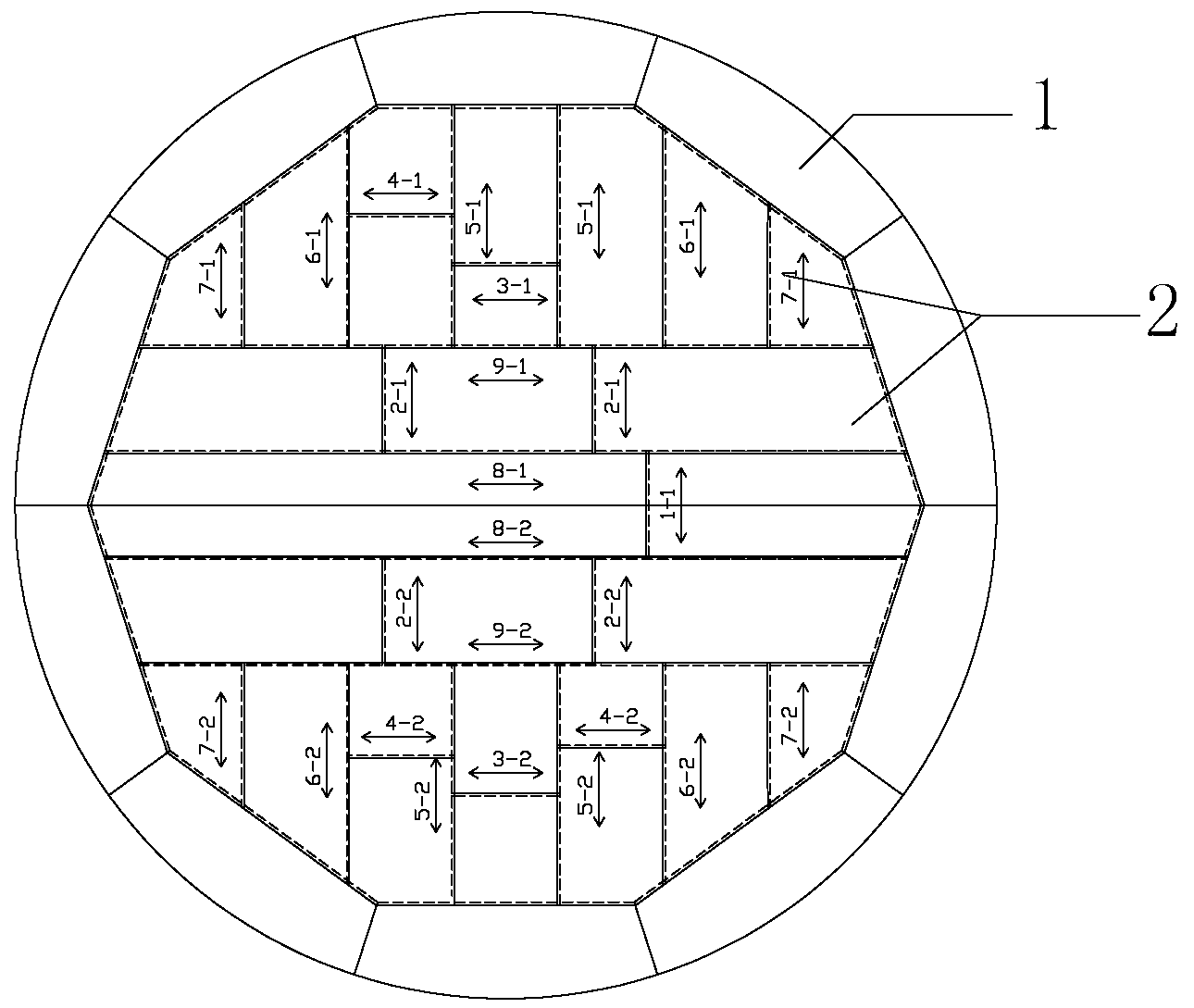

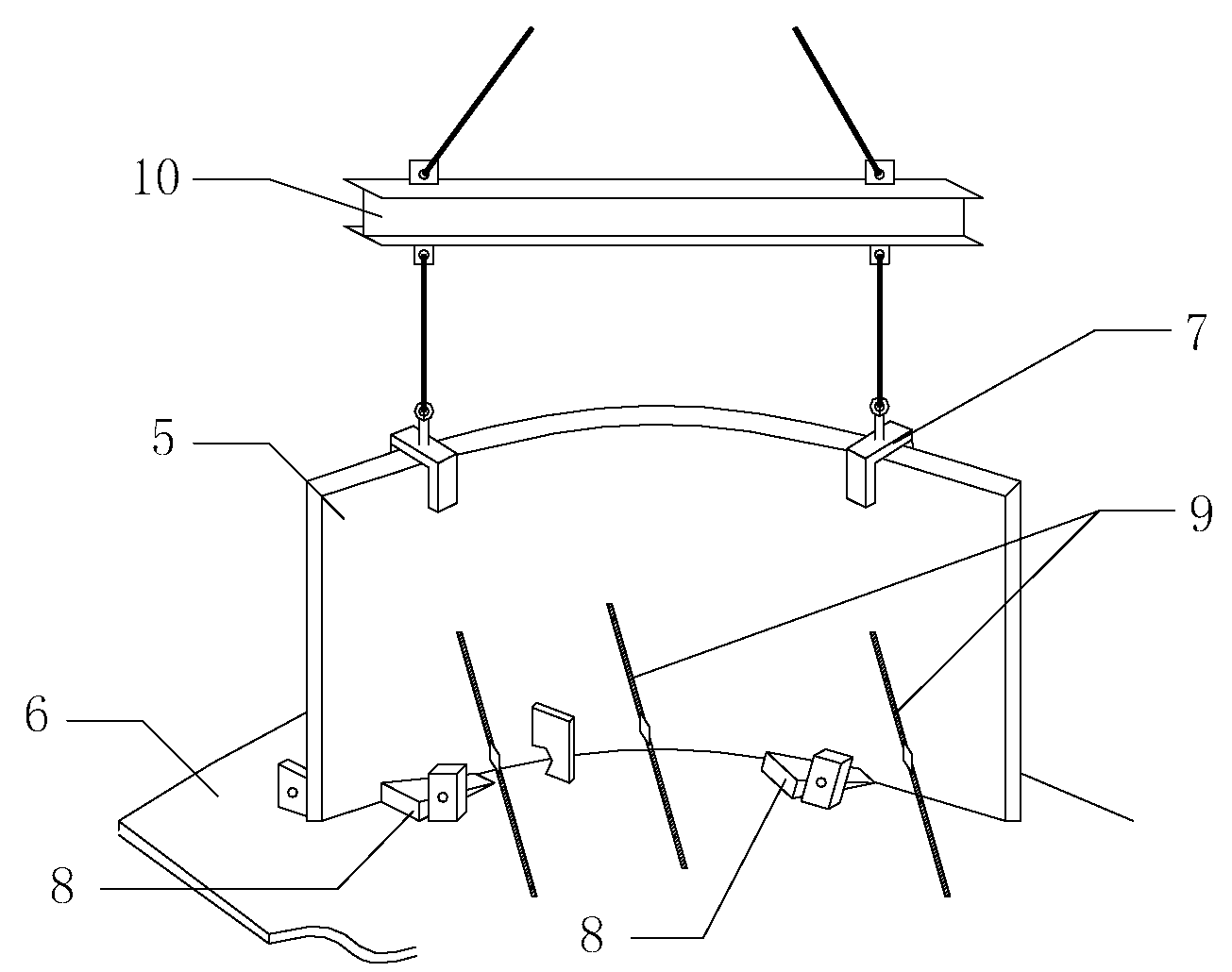

[0049] The welding method for making a tank of the present invention is characterized in that it comprises the following steps:

[0050] a. Manufacturing and welding of tank bottom plate, including:

[0051] (1), floor laying

[0052] Set up the layout of the bottom plate during the laying of the bottom plate. For the bottom plate with the bow-shaped edge plate in the layout drawing, first take the center point of the tank bottom as the center and the radius of the tank as the radius, draw the outer edge assembly line of the edge plate, and then fix the bottom plate by spot welding , and then spot-weld and fix the medium-width panels according to the layout diagram, and the lap length of each panel is 50mm; before the bottom panel is cut, the uneven deformation caused by the individual panels entering the site or due to the uneven placement of raw materials during unloading Larger plates can be used after being rolled back and forth with a plate rolling machine.

[0053] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com