Magnetic material powder forming mold with non-magnetic isolating structure

A technology of isolation structure and magnetic material, applied in the field of mold manufacturing, can solve the problems of affecting performance, uneven magnetic field distribution, inconsistent blank orientation direction, etc., to achieve the effect of improving quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

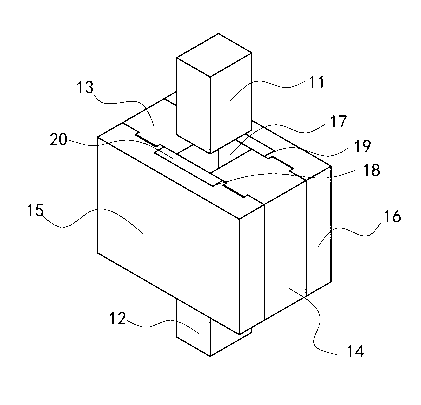

[0024] Such as figure 2 As shown, the magnetic material powder molding die with a non-magnetic isolation structure according to the present invention includes an upper pressing head 11 , a lower pressing head 12 , a female mold and an insulating structure 20 . Described female mold comprises front side plate 13, back side plate 14, left side plate 15 and right side plate 16, and described front side plate 13, described back side plate 14, described left side plate 15 and described right side plate A mold cavity 17 is formed around the side plate 16, and the upper indenter 11 and the lower indenter 12 match the mold cavity 17, and press into the mold cavity 17 from above and below the mold cavity 17 respectively. . The left side plate 15 and the right side plate 16 are respectively provided with concave structures 18, 19 on one side in the mold cavity 17, the isolation structure 20 cooperates with the concave structures 18, 19, and the isolation structure 19 is made of non-m...

Embodiment 2

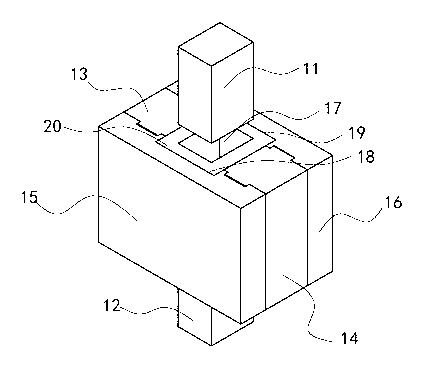

[0029] Such as image 3 As shown, the isolation structure 20 is a hollow cylindrical body, and its cross section can be square or rectangular. Two opposite sides of the cylindrical body are respectively located in the concave structures 18, 19, and the other two opposite sides are respectively connected The inner sides of the front side plate 13 and the rear side plate 14 are in close contact. By adopting this embodiment, the isolation structure 20 is taken as a whole, which is convenient for installation. When adopting this embodiment, the length of the front side plate 13 and the rear side plate 14 needs to be shortened adaptively, that is, the area of the mold cavity 17 is enlarged, and then the isolation structure 20 is placed on the mold cavity 17 The inner wall is easy to install.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com