Method for separating catalyst by using ceramic membrane filter, and apparatus thereof

A filter separator and ceramic membrane technology, which is applied in the chemical industry, can solve problems such as energy-consuming and cost-intensive, inconsistent operation cycles, and achieve the effects of reducing times and costs, prolonging operation cycles, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

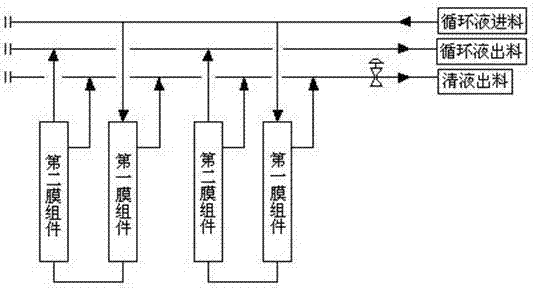

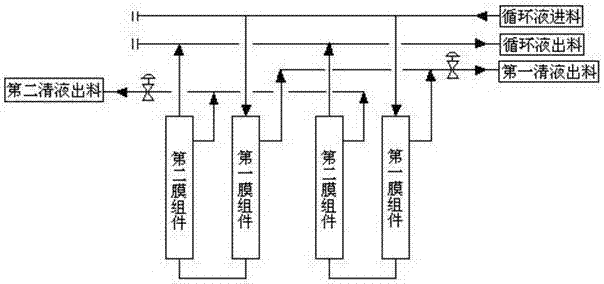

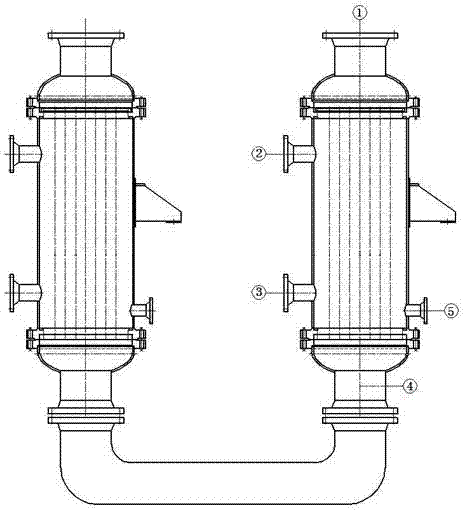

[0020] refer to Figure 2~3 , a method for separating catalysts by ceramic membrane filters, comprising the following steps: (1) providing a device for separating catalysts by ceramic membrane filters, the device comprising a reactor, two or three sets of parallel ceramic membrane filter separators and Reaction product intermediate tank, each group of ceramic membrane filter separators contains two series of first membrane modules and second membrane modules; (2) The reaction turbid liquid mixture is pressurized to each group of ceramic membrane filtration through the circulation pump of the reactor Separator, each first membrane module is connected to the circulating liquid feed pipe of the reactor, each second membrane module is connected to the circulating liquid outlet pipe of the reactor, and each first membrane module and the second membrane modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com