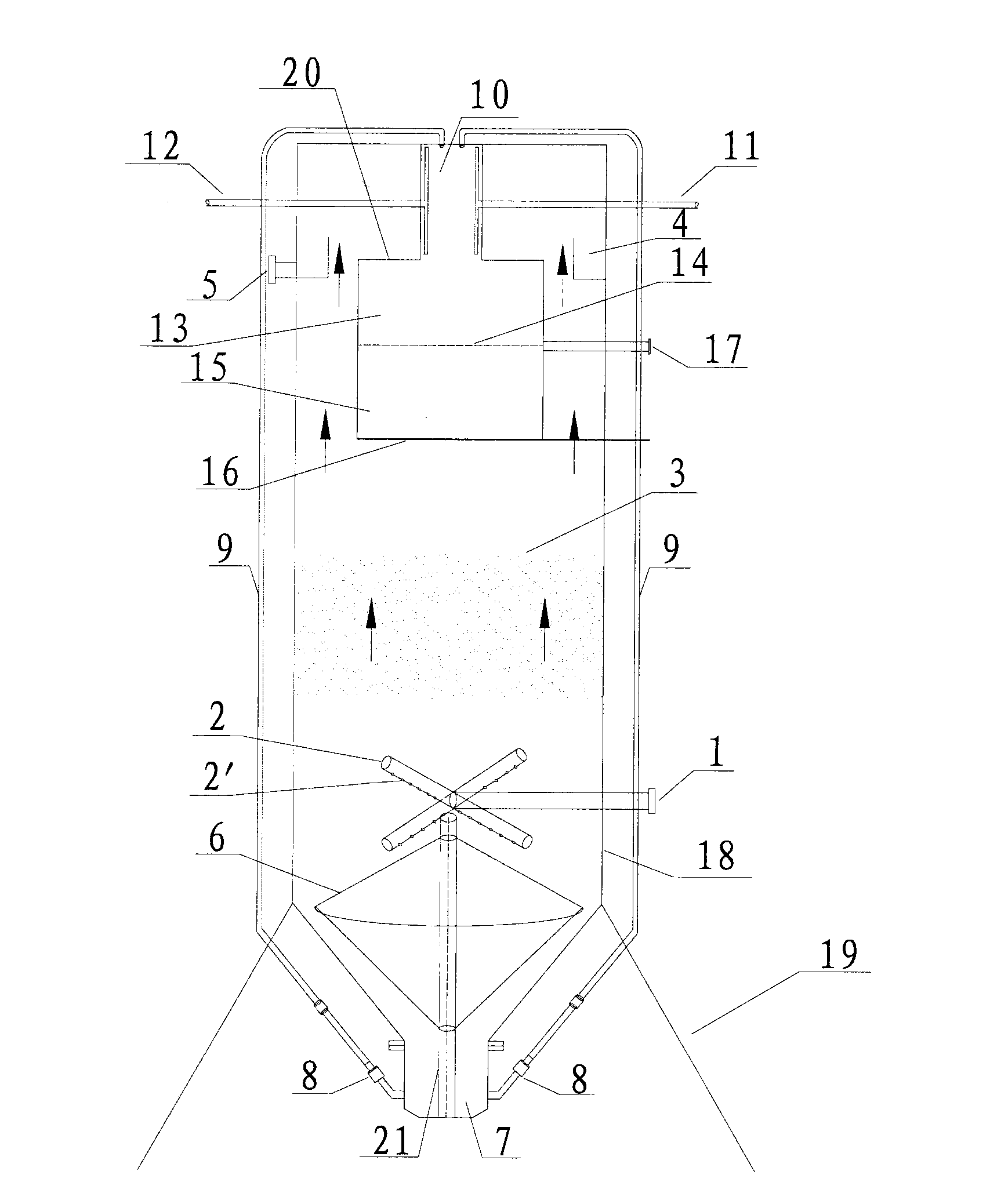

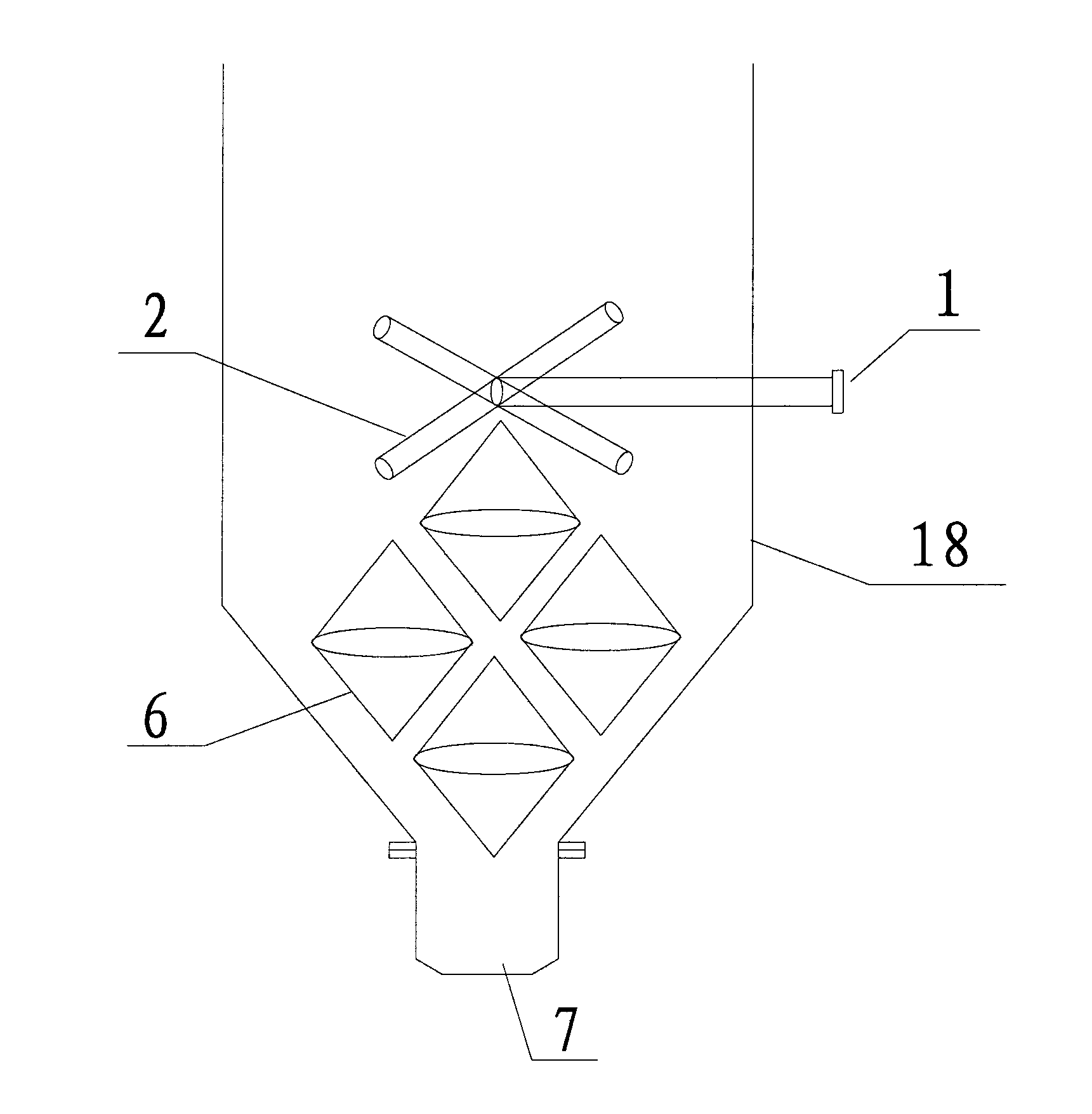

Water treatment method and device for synchronously realizing filtering and back washing

A technology for backwashing water and a treatment device, applied in the field of water treatment, can solve the problems of low wastewater treatment efficiency and process performance, and achieve the effects of improving sewage interception capacity and work efficiency, saving flushing water, and reducing energy consumption and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

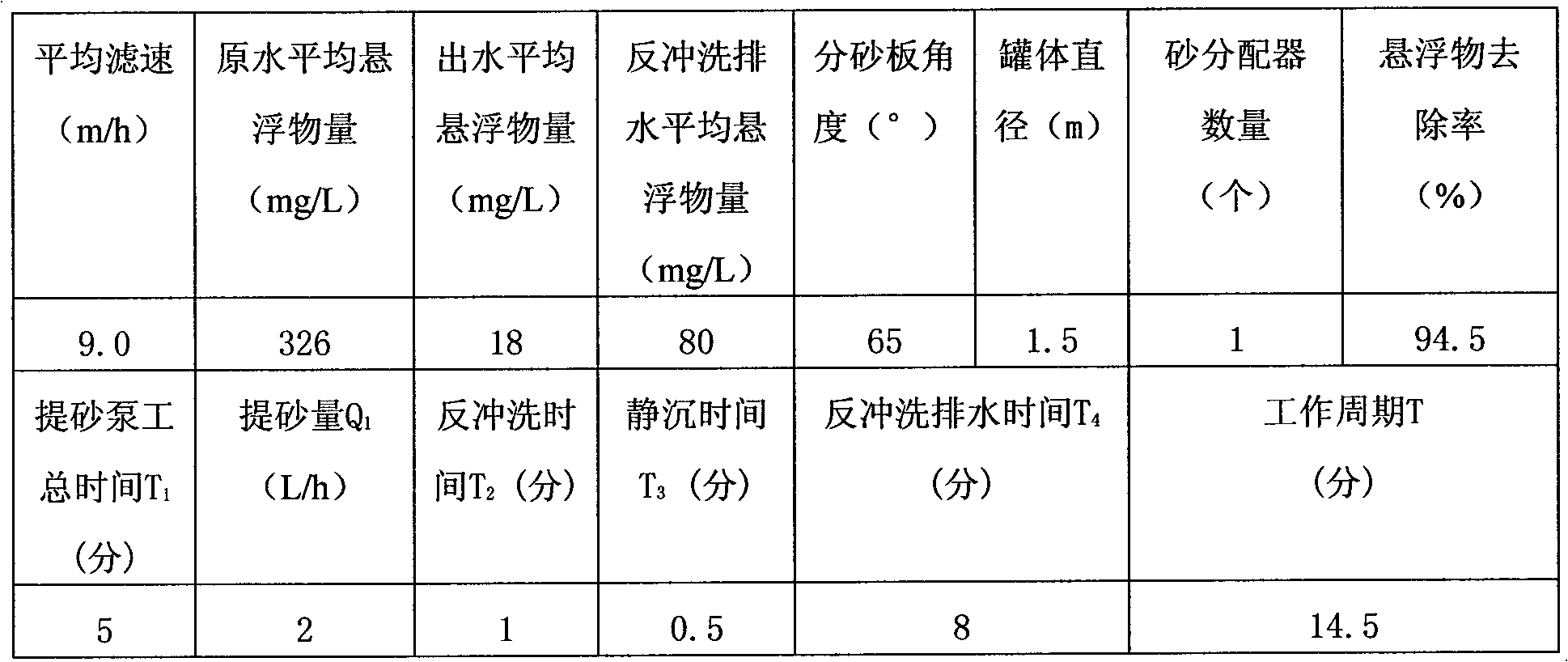

[0032] Table 1 Test conditions and results of synchronous filtration and backwashing water treatment device (1)

[0033]

[0034] The diameter of the filter tank is 1.5m, one sand distributor, and the angle of the sand dividing plate is 65°. The average amount of suspended solids in raw water is 326mg / L, and the average filtration rate is 9.0m / h. The average amount of suspended solids in the water was measured to be 18mg / L. The removal rate of suspended matter is 94.5%. Sand lifting pump working time T 1 is 5 minutes, and the amount of sand extraction is Q 1 2L / h, backwashing time is T 2 is 1 minute, and the settling time T 3 0.5 minutes, backwash water emptying time T 4 For 8 minutes, the average amount of suspended solids in the backwash drainage was measured to be 80mg / L. The duty cycle T is 14.5 minutes.

Embodiment 2

[0036] Table 2 Test conditions and results of synchronous filtration and backwashing water treatment device (2)

[0037]

[0038] The diameter of the filter tank is 1.8m, there are 2 sand distributors, and the angle of the sand dividing plate is 62°. The average amount of suspended solids in raw water is 310mg / L, and the average filtration rate is 9.0m / h. The average suspended solids in the water was measured to be 15mg / L. The removal rate of suspended matter is 95.2%. Sand lifting pump working time T 1 is 8 minutes, the amount of sand extraction Q 1 2.5L / h, backwashing time is T 1 1.5 minutes, settling time T 3 is 1.5 minutes, and the backwash water emptying time is T 4 For 8.5 minutes, the average amount of suspended solids in the backwash drainage was measured to be 76mg / L. The duty cycle T is 19.5 minutes.

Embodiment 3

[0040] Table 3 Test conditions and results of synchronous filtration and backwashing water treatment device (3)

[0041]

[0042] The diameter of the filter tank is 2m, there are 4 sand distributors, and the angle of the sand dividing plate is 60°. The average amount of suspended solids in raw water is 330mg / L, and the average filtration rate is 9.0m / h. The average suspended solids in the water was measured to be 13mg / L. The removal rate of suspended matter is 96.1%. Sand lifting pump working time T 1 10 minutes, the amount of sand extraction Q 1 2.5L / h, backwash time T 2 is 2 minutes, the settling time T 3 2 minutes, backwash water emptying time T 4 For 10 minutes, the average amount of suspended solids in the backwash drainage was measured to be 63mg / L. The duty cycle T is 24 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com