Post-harvest treatment and storage method for potato minituber produced by fog culture method

A technology for miniature seed potatoes and post-harvest treatment, which is applied in the fields of botanical equipment and methods, agricultural machinery and implements, fruit suspension devices, etc. The effect of storage period and less water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

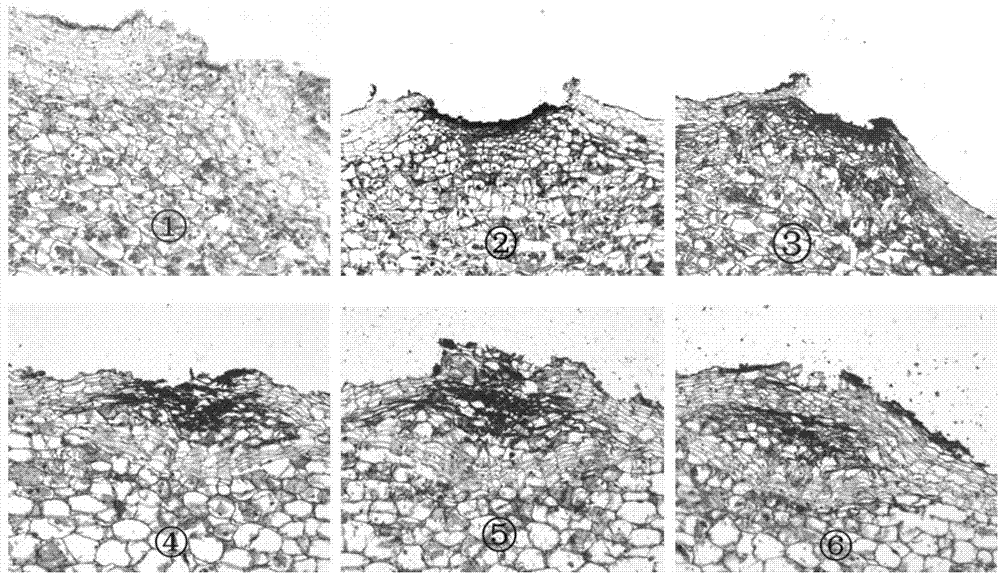

[0014] Changes in the structure of the cork layer of potato microtubers during the treatment of aeroponic potato microtubers before low-temperature storage in the Potato Crop Research Institute of Yunnan Agricultural University, see Figure 1 to Figure 3 shown.

[0015] 1) Processing process:

[0016] a. Sterilization of tubers after harvest: Immediately after potato tubers are harvested, put them in a treatment room with a temperature of 15-18°C and a humidity of 85%-95%, and spread them out in clean containers such as plastic baskets, with a thickness of no more than 3 layers. The next day, the tubers were evenly sprayed with a bactericidal solution containing 5 grams of carbendazim and 5 grams of chlorothalonazim per liter of water, and then the surface of the tubers was air-dried to kill the pathogens on the surface of the tubers.

[0017] b. Tubers turn green: place the sterilized tubers in a green room with a temperature of 15-18°C, a humidity of 85%-95%, and 24-hour li...

Embodiment 2

[0029] Effects of applying the technology of the present invention to the potato virus-free microtubers produced by the Potato Crop Research Institute of Yunnan Agricultural University using the aeroponic method and storing them.

[0030] 1) Sterilization of tubers after harvest: On May 23, 2010, immediately after potato tubers were harvested, they were placed in a treatment room with a temperature of 18-20°C and a humidity of 85%-95%, spread them out in plastic baskets, and placed the tubers for 2 Layer, spray the tubers evenly with a fungicidal solution containing 5 grams of chlorazine and 5 grams of chlorothalonazim per liter of water, and then air dry the surface of the tubers.

[0031] 2) Tubers turn green: Put the sterilized tubers into a green room with a temperature of 18-20°C, a humidity of 85%-95%, and 24-hour light on the second day, and spread them out in a plastic basket with a thickness of 3 layers. Frequently stir until the flesh color of the tubers turns green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com