Method for cooling ethylene oxide product of ethylene oxide/glycol device

A technology of ethylene oxide and cooling method, which is applied in the field of cooling ethylene oxide products of ethylene oxide/ethylene glycol devices, can solve problems such as potential safety hazards, and achieve the goal of ensuring storage safety and solving pipeline blockage caused by material polymerization Potential safety hazards, the effect of saving a lot of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

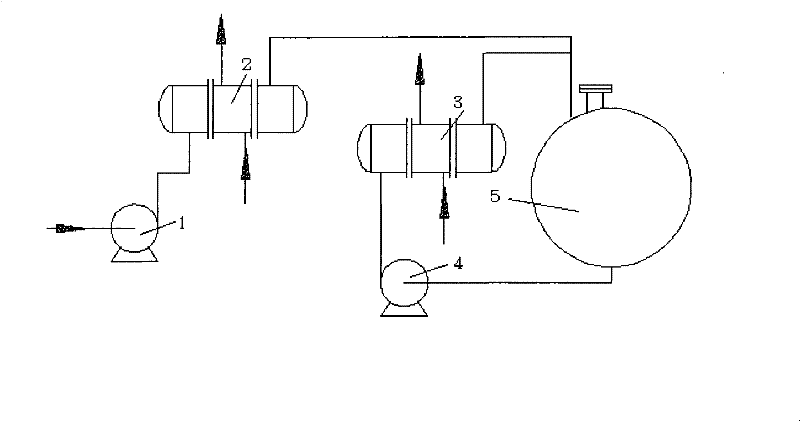

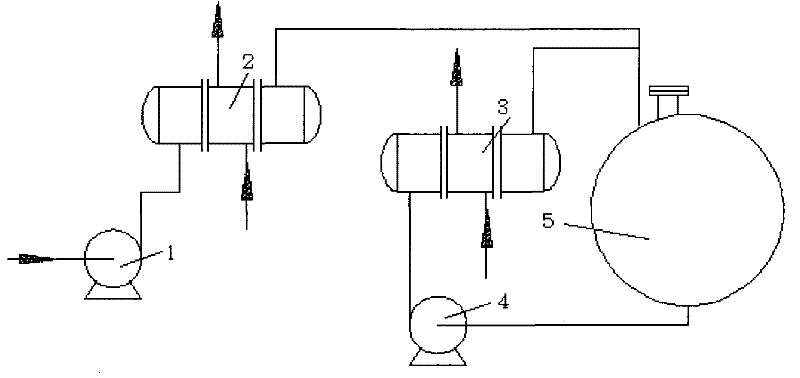

[0008] The cooling method of the ethylene oxide product of the ethylene oxide / ethylene glycol plant of the present invention is described below according to the accompanying drawings.

[0009] An ethylene oxide product circulating water cooler 2 is connected to the outlet of the ethylene oxide product delivery pump 1 of the existing ethylene oxide / ethylene glycol device, the ethylene oxide goes through the pipe layer, and the circulating water goes through the shell layer, Then the ethylene oxide product circulating water cooler 2 is connected with the ethylene oxide product circulating refrigerant cooler 3 and then connected with the ethylene oxide product storage tank 5 through the ethylene oxide product circulating pump 4 .

[0010] In the implementation process of the ethylene oxide product water cooler, it is necessary to first determine the temperature difference between the outlet temperature of the ethylene oxide product delivery pump and the circulating water, determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com