Button-type five-dimensional force sensor

A five-dimensional force and sensor technology, applied in the field of sensors, can solve problems such as the sensor diameter is too large, the sensor cannot do it, the circuit board is in contact with the sole of the shoe, etc., to achieve effective measurement, reliable lead out signal lines, and reduce the diameter of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

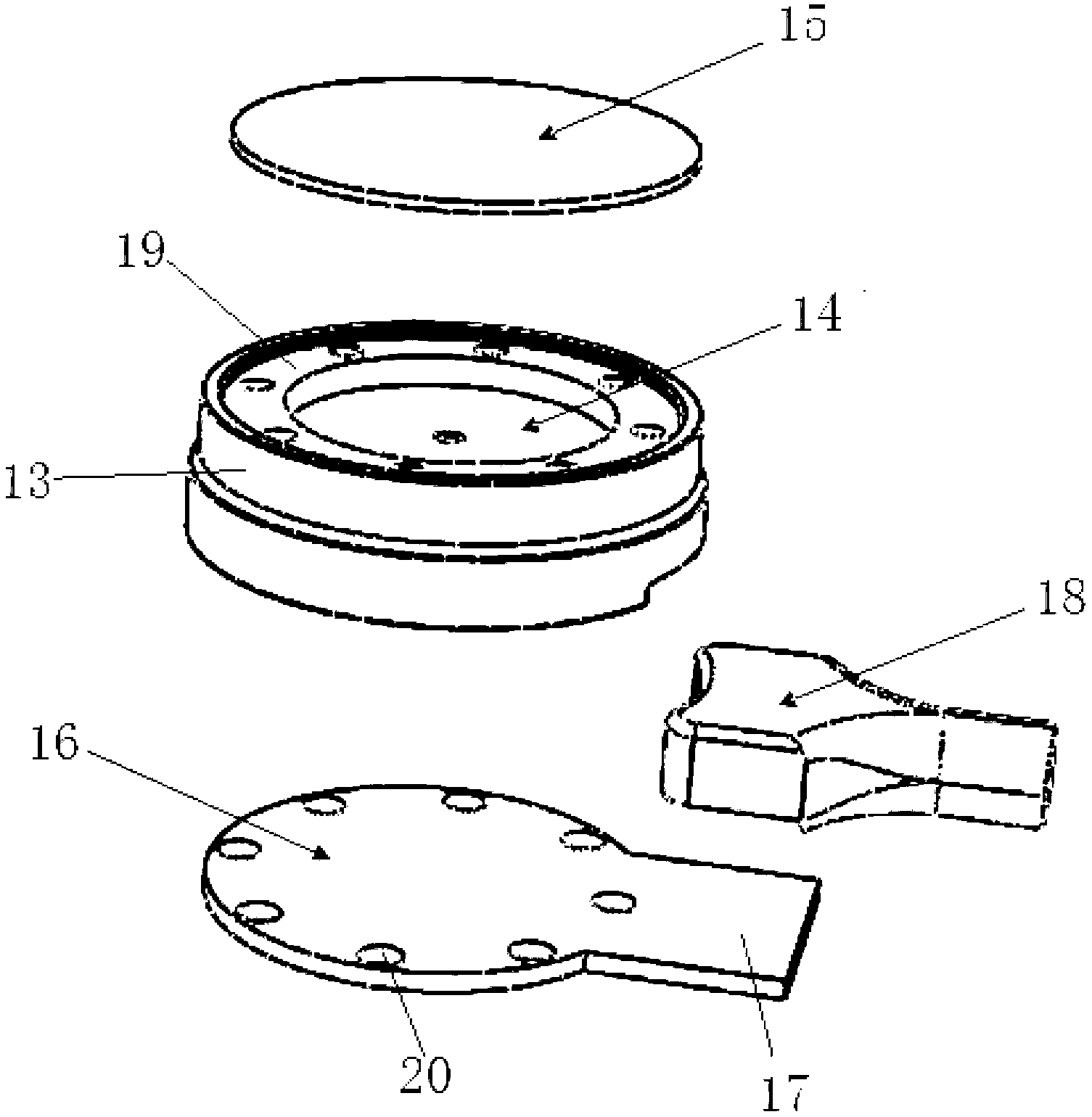

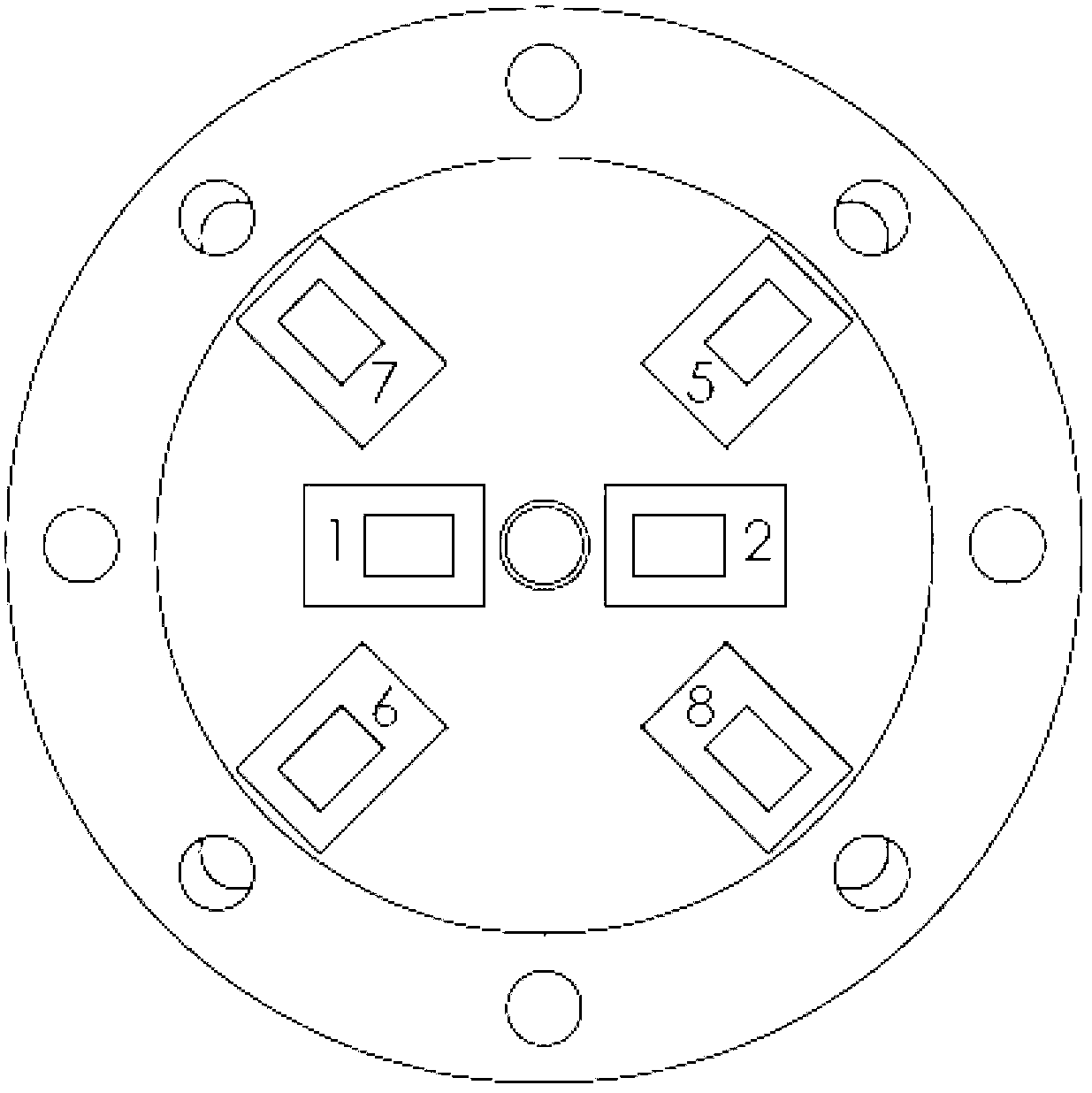

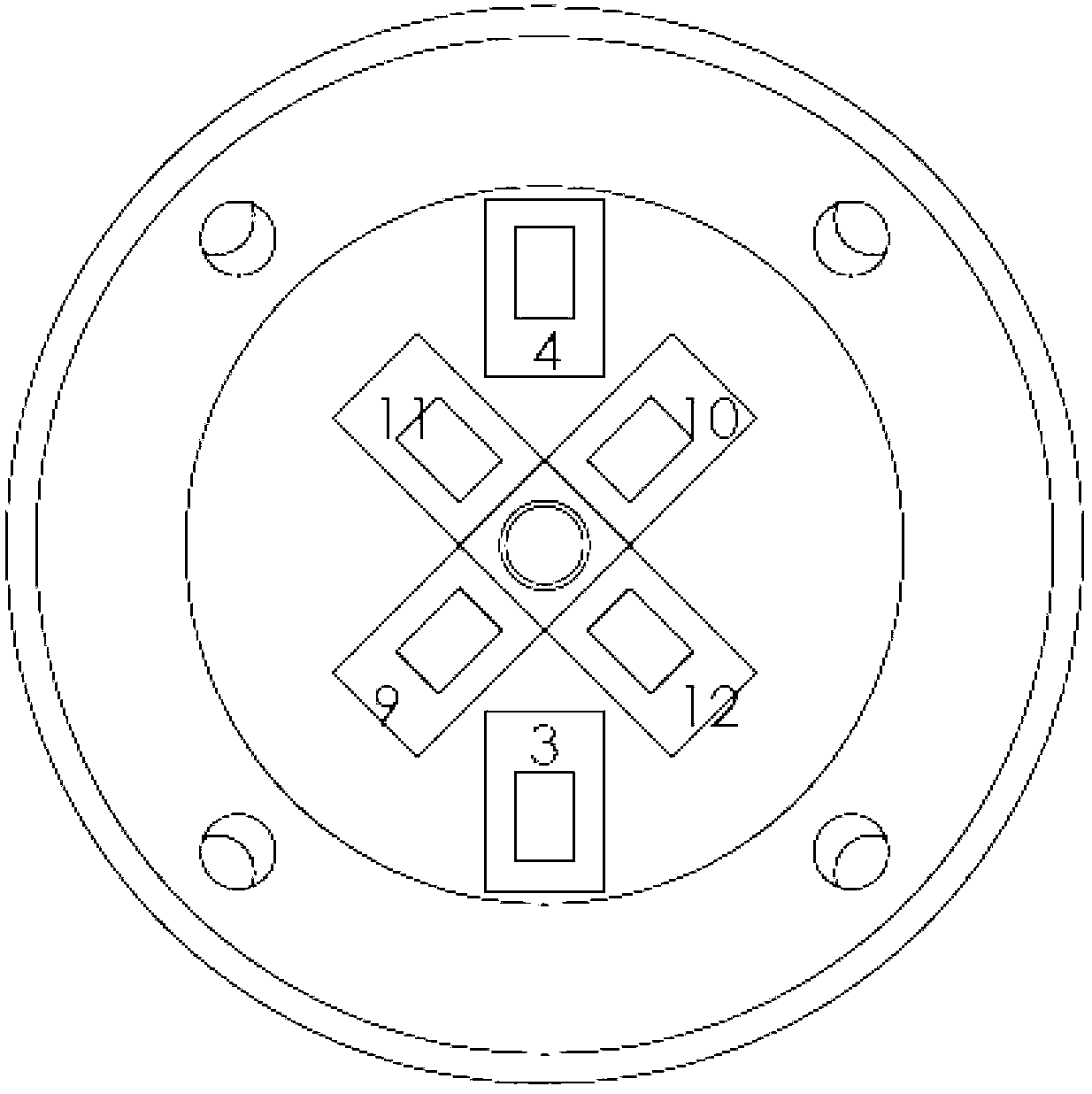

[0024] Such as Figure 1-4 As shown, a button-type five-dimensional force sensor includes a cylindrical base 13, a base plate 14 is arranged in the cylindrical base 13, and a circular cover plate 15 is arranged on the upper end of the cylindrical base 13, The lower end of the cylindrical base 13 is provided with a wiring circuit board 16, and one side of the wiring circuit board 16 is provided with a handle 17, and one side of the cylindrical base 13 is provided with an outlet rubber head 18, and the outlet rubber head 18 One side is closely attached to the side wall of the cylindrical base 13, and the bottom of the outlet rubber head 18 is fixed on the handle of the wiring circuit board 16, and six strain gauges are attached to the upper and lower end surfaces of the substrate 14 respectively. The strain gauges 1 and 2 are affixed to the middle of the upper end surface of the substrate 14 in a straight line, and the strain gauges 5, 6, 7 and 8 are arranged in a ring around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com