A composite air intake system for real-time realization of oxygen-enriched combustion in internal combustion engines

An air intake system, oxygen-enriched combustion technology, applied in combustion air/combustion-air treatment, charging system, mechanical equipment, etc., can solve the problem that the internal combustion engine cannot realize real-time oxygen production, etc., to improve the performance and function of oxygen-enriched combustion Powerful, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

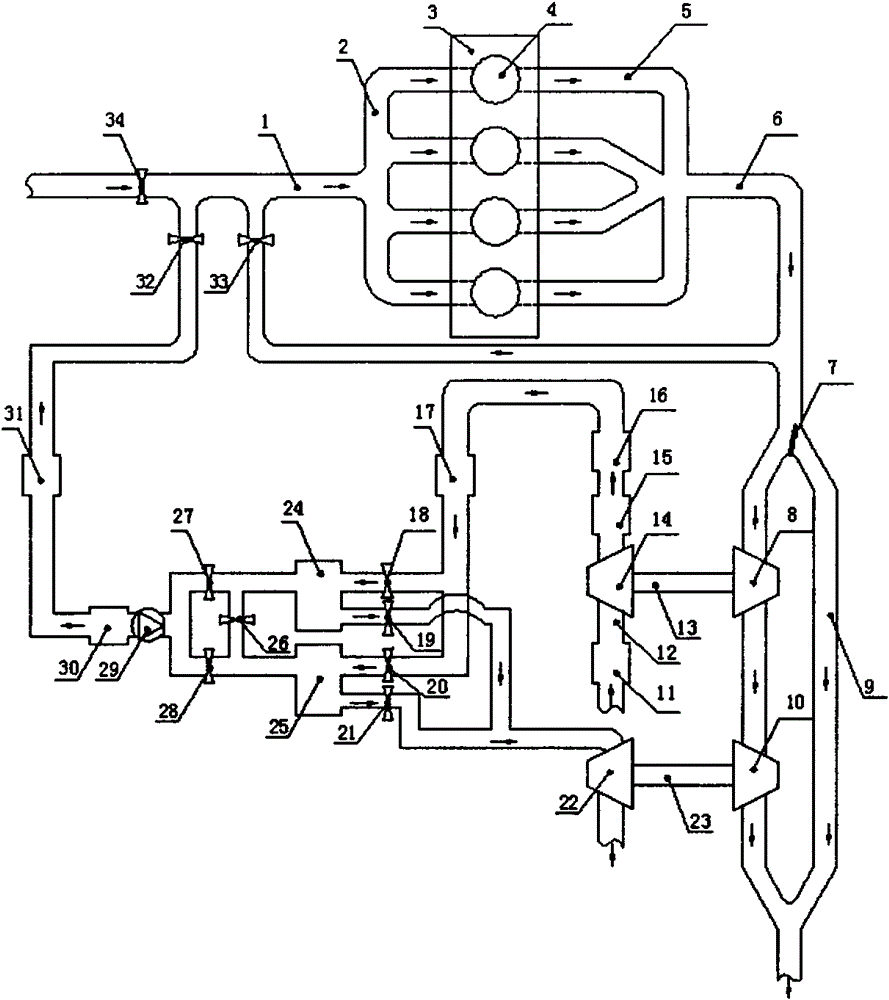

[0022]According to a preferred example of the present invention, a certain type of vehicle diesel engine is equipped with a composite air intake system that realizes the oxygen-enriched combustion of the internal combustion engine in real time, so as to achieve the purpose of realizing oxygen-enriched combustion on the internal combustion engine, improving combustion performance and emission performance. In this example, the two-stage exhaust gas turbocharging system of the exhaust system is modified, the first-stage exhaust turbine (8) is used as the power source of the compressor (14) of the pressure swing adsorption oxygen generation system, and the second-stage exhaust turbine The gas turbine (10) serves as the power source for the vacuum pump (22) of the pressure swing adsorption oxygen generation system. When the internal combustion engine is working stably, there are three sources of intake air: the air in the environment, the oxygen produced by the pressure swing adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com