Construction method for cantilever assembly steel arches for cast-in-situ large-span concrete arch bridge

A construction method and technology for steel arches, which are applied in the field of cantilevered steel arches for arch bridges, can solve problems such as being difficult to implement and cumbersome, and achieve the effects of reasonable structure, advanced technology, and reliable fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

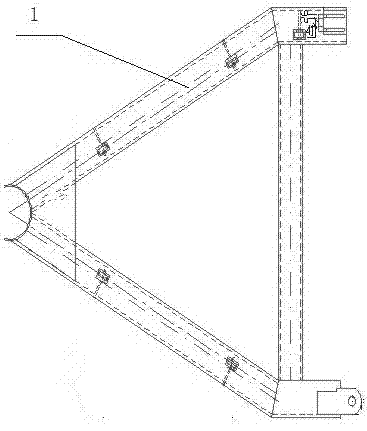

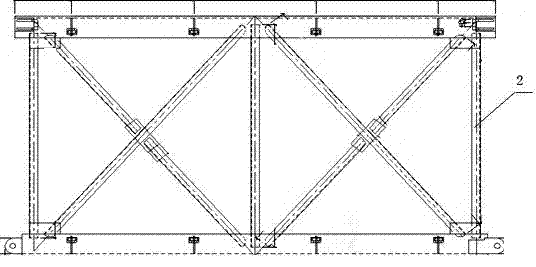

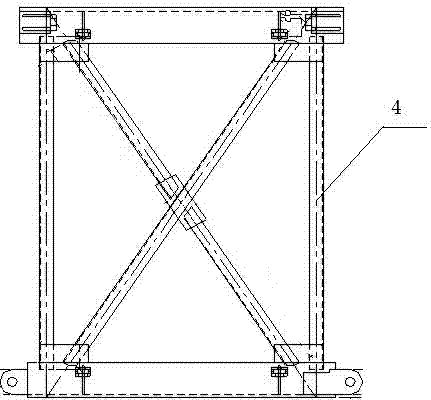

[0039] Construction method of cantilevered steel arch frame of cast-in-place long-span concrete arch bridge. The steel arch frame is composed of standard segment 2, adjustment segment 4, vault segment 3 and arch foot segment 1. The construction process mainly includes the steel arch Frame assembly and steel arch lateral movement are carried out simultaneously on both sides of the bridge span during construction. Its characteristics are: in the process of segmental connection, the horizontal system adopts the horizontal connection method, and the top surface of the arch frame and the ground adopt the flat connection method; The connection between the sections is connected by the lower chord pin shaft and the upper chord bolt connection; the specific construction is carried out according to the following steps:

[0040] Step 1, set the steel arch abutment; the steel arch abutment is a temporary abutment used to support the cast-in-place construction load. At the same time as the...

Embodiment 2

[0050] Taking the Fuxi River Bridge as an example, the Fuxi River Bridge is located on the eastern edge of the Guizhou Plateau. The bridge area is a plateau structure erosion-denudation low-middle mountain valley landform. The altitude near the bridge area is between 324.5 and 364m, with a relative height difference of 39m. The covering layer of the bridge area is cultivated soil, silty clay and alluvial-diluvial pebble soil. The upper structure of Fuxi River Bridge adopts 5×20m (prestressed concrete hollow slab) + 120m (reinforced concrete box arch) +2 ×20m (prestressed concrete hollow slab). The main hole of the lower structure adopts cast-in-place reinforced concrete abutment and cast-in-place concrete foundation, and reinforced concrete bent piers are set on the arch, and the junction piers No. The pile foundation and abutment foundation are cut and expanded foundations, and the abutments on both banks are gravity U-shaped abutments.

[0051]The steel arch is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com