Degradation method of resin matrix glass fiber reinforced plastic composite materials

A technology of composite materials and glass fiber reinforced plastics, which is applied in the chemical industry, can solve problems such as undiscovered and environmental impacts, and achieve the effects of low cost, low requirements, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

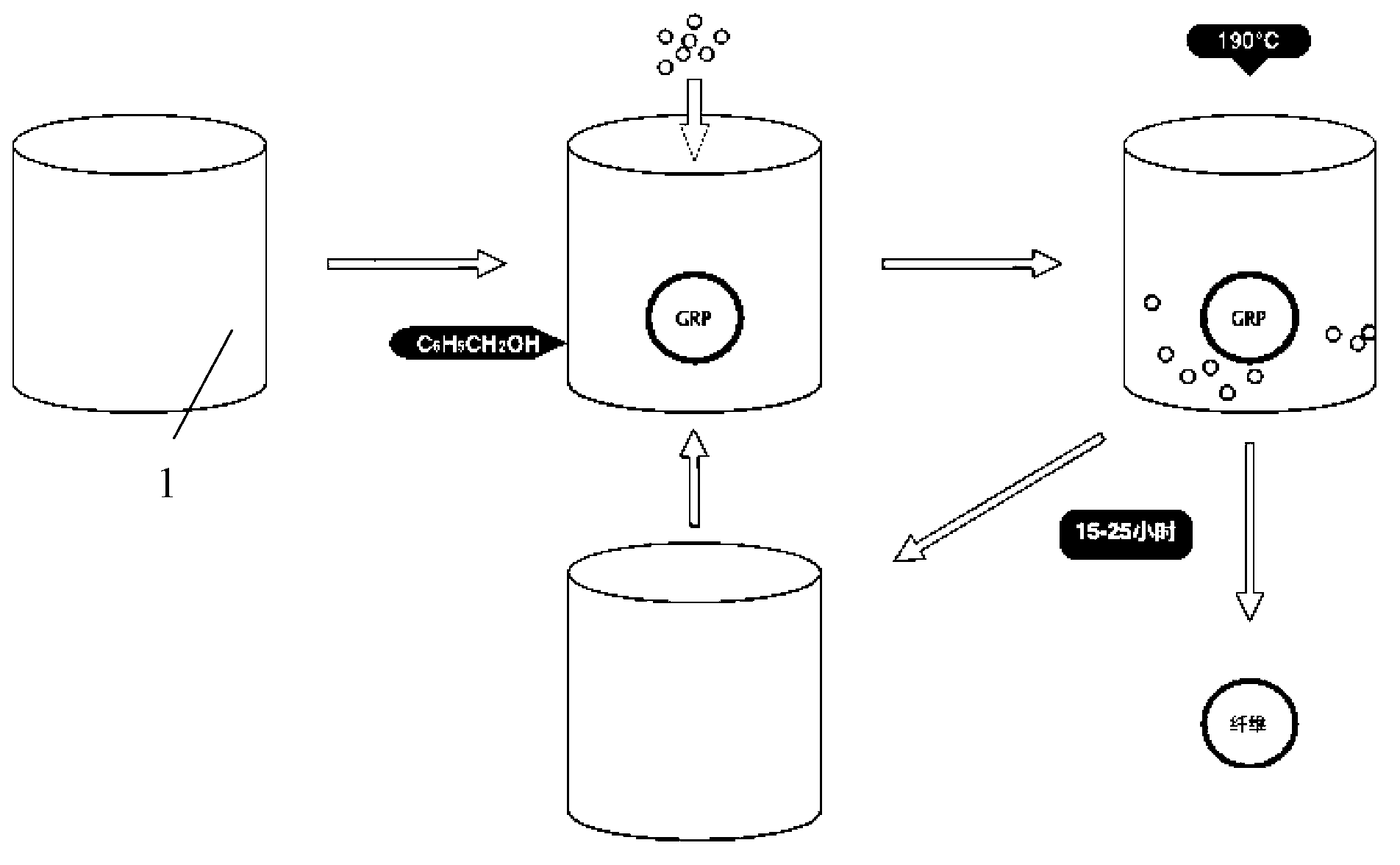

[0015] Such as figure 1 As shown, the degradation method of the resin-based FRP material provided in this example is to add 2 / 3 capacity of benzyl alcohol into the reaction kettle 1 under normal pressure conditions, and then add 300g of the ortho-phthalic unsaturated polyester resin base that needs to be degraded. For FRP composite materials, it should be ensured that the composite materials are completely immersed in benzyl alcohol, then 0.3g of tripotassium phosphate is added, and then the temperature of the reactor 1 is raised to 190°C, and the temperature is maintained for 20h, thus the above-mentioned ortho-phthalic unsaturated The polyester resin-based FRP composite material is thermally degraded into glass fibers and o-phthalic unsaturated polyester resin, and finally the glass fiber and o-phthalic unsaturated polyester resin are separated.

Embodiment 2

[0017] Such as figure 1 As shown, the degradation method of the resin-based FRP material provided in this embodiment is to add 2 / 3 capacity of benzyl alcohol in the reaction kettle 1 under normal pressure conditions, and then add 346kg of 10mm thick m-benzene type unsaturated polystyrene that needs to be degraded. For the ester resin-based FRP composite material, it should be ensured that the composite material is completely immersed in benzyl alcohol, then 3.46g of tripotassium phosphate is added, and then the temperature of the reaction kettle 1 is raised to 190°C, and the temperature is maintained for 25h, thus the above m-benzene Type unsaturated polyester resin-based FRP composite material is thermally degraded into glass fiber and isophthalic unsaturated polyester resin, and finally the glass fiber and isophthalic unsaturated polyester resin are separated.

Embodiment 3

[0019] Such as figure 1 As shown, the degradation method of the resin-based FRP material provided in this embodiment is to add 2 / 3 capacity of benzyl alcohol in the reaction kettle 1 under normal pressure conditions, and then add 8mm thick (1.05kg) vinyl resin that needs to be degraded It should be ensured that the resin-based FRP material is completely submerged in benzyl alcohol, then 1g of tripotassium phosphate is added, and then the temperature of the reactor 1 is raised to 190°C, and the temperature is maintained for 22 hours, thereby compounding the resin-based FRP The material is thermally degraded into glass fiber and resin, and finally the glass fiber and resin are separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com