Catalyst component for high temperature olefin polymerization, and preparation method thereof

A high-temperature polymerization and catalyst technology, which is applied in the field of catalysts and high-temperature polymerization of olefins, can solve the problems of complex operation, complex polymerization process, high-temperature polymerization activity and polymer isotacticity to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

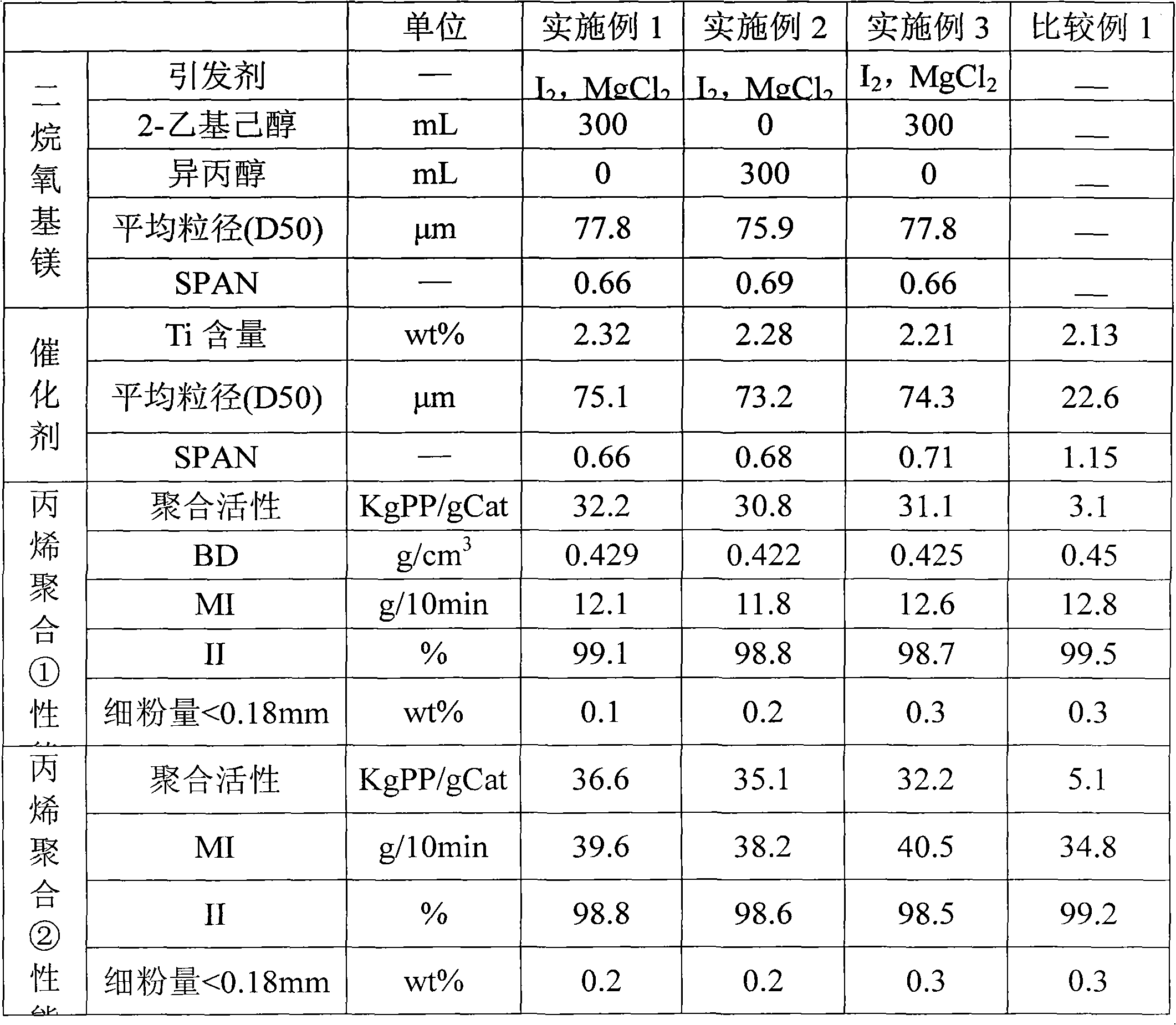

Embodiment 1

[0062] (1) Preparation of dialkoxymagnesium carrier

[0063] After the 16L pressure-resistant reactor with a stirrer was fully replaced with nitrogen, 10200 mL of ethanol, 300 mL of 2-ethylhexanol, 12 g of iodine and 8 g of magnesium chloride were added to the reactor to dissolve them. After stirring, the temperature was raised until the reflux temperature of the reaction system was reached; then 640 g of magnesium powder was added successively, and the reaction was carried out until no hydrogen gas was discharged. It is then washed, separated and dried. The dried dialkoxymagnesium carrier 1# was obtained.

[0064] (2) Preparation of catalyst components

[0065] Take the above-mentioned dialkoxymagnesium carrier 1#650g, 3250mL of toluene, and 130mL of di-n-butyl phthalate (DNBP) to prepare a suspension for use; Toluene 2600mL and titanium tetrachloride 3900mL, cool down to -5°C, then add the previously prepared suspension into the kettle, keep the temperature constant until...

Embodiment 2

[0071] Except that in (1) the preparation of the dialkoxymagnesium carrier, 300 ml of isopropanol was added and 300 ml of 2-ethylhexanol was not added, the others were the same as in Example 1.

Embodiment 3

[0073] Except that 130 mL of diisobutyl phthalate (DIBP) was added in the preparation of (2) catalyst component to replace 130 mL of di-n-butyl phthalate (DNBP), the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com