Low molecular weight (LMW) xanthan gum and preparation method thereof

A xanthan gum and raw material technology, applied in the field of low molecular weight xanthan gum and its preparation, can solve the problems of low molecular weight, wide molecular weight range, narrow molecular weight distribution width, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

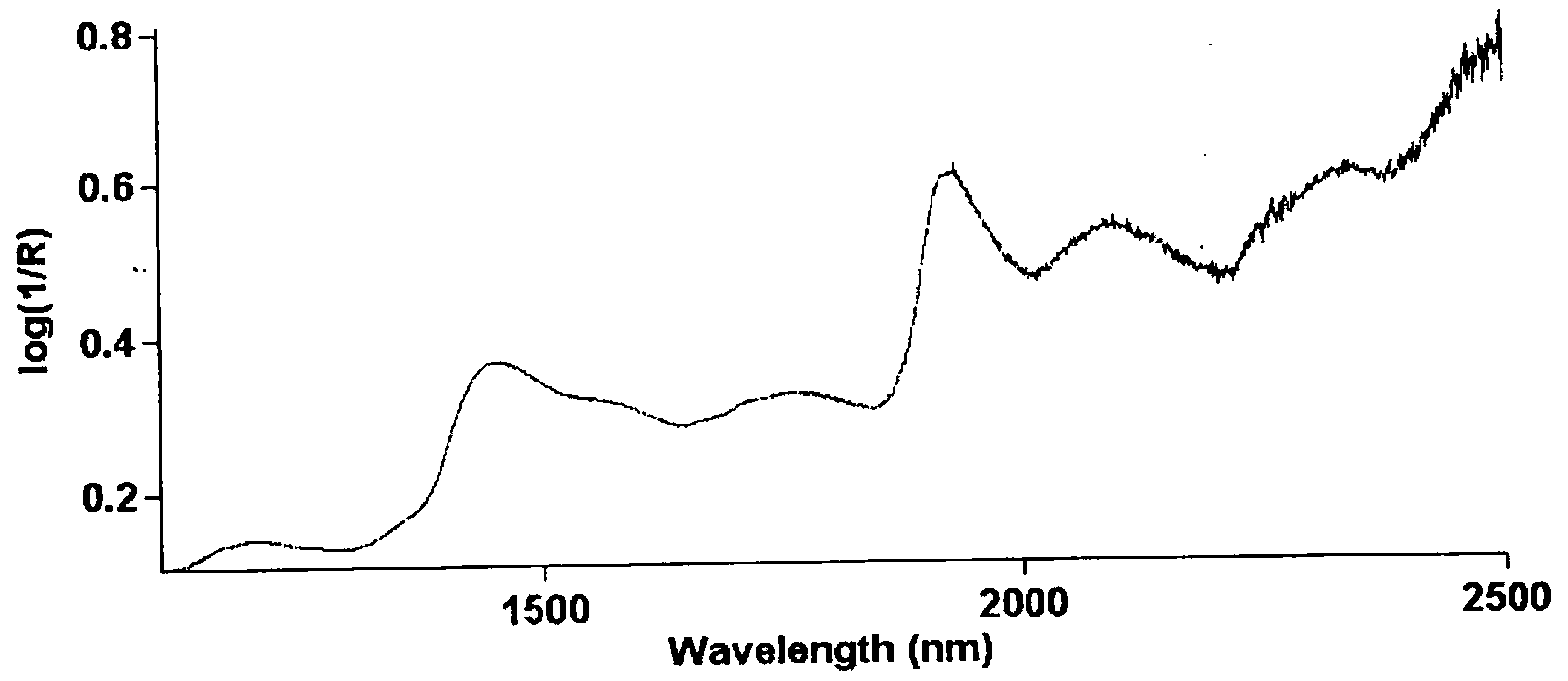

Image

Examples

Embodiment 1

[0029] 1. Dissolution of xanthan gum

[0030] Weigh xanthan gum, calcium chloride and sodium tetraborate, set aside.

[0031] While stirring, slowly add xanthan gum to the water, and continue stirring for 2 hours until the xanthan gum is completely dissolved. At this time, the concentration of the xanthan gum solution is 3.0% (that is, every 3.0g xanthan gum is dissolved in 100ml water).

[0032] 2. Xanthan Gum Extract

[0033] Under agitation, slowly add calcium chloride and sodium tetraborate to the xanthan gum solution prepared in step 1, the consumption of calcium chloride is 4% of the xanthan gum quality, and the consumption of sodium tetraborate is xanthan gum 2ppm of mass, stir evenly. Then add ethanol with 3 times the volume of water for dissolving xanthan gum while stirring, so that the ethanol concentration in the solution is 65%. After adding ethanol, continue stirring for 30 minutes to precipitate filaments.

[0034] 3. separate

[0035] The precipitated fil...

Embodiment 2

[0052] 1. Dissolution of xanthan gum

[0053] Weigh food additives xanthan gum, calcium chloride and sodium tetraborate, set aside.

[0054] While stirring, slowly add xanthan gum to the water, and continue stirring for 3 hours until the xanthan gum is completely dissolved. At this time, the concentration of the xanthan gum solution is 5.0%.

[0055] 2. Xanthan Gum Extract

[0056]Under agitation, slowly add calcium chloride and sodium tetraborate to the xanthan gum solution prepared in step 1, the consumption of calcium chloride is 5.0% of the xanthan gum quality, and the consumption of sodium tetraborate is xanthan gum The quality of 4ppm, stir well. Then add ethanol with 1.5 times the volume of water for dissolving xanthan gum while stirring, so that the ethanol concentration in the solution is 57%. After adding ethanol, continue stirring for 30 minutes to precipitate filaments.

[0057] 3. separate

[0058] The precipitated filaments are dehydrated and separated wit...

Embodiment 3

[0067] 1. Dissolution of xanthan gum

[0068] Weigh xanthan gum, calcium chloride and sodium tetraborate, set aside.

[0069] While stirring, slowly add xanthan gum to the water, and continue stirring for 1 hour until the xanthan gum is completely dissolved. At this time, the concentration of the xanthan gum solution is 1.5% (g / ml).

[0070] 2. Xanthan Gum Extract

[0071] Under agitation, slowly add calcium chloride and sodium tetraborate to the xanthan gum solution prepared in step 1, the consumption of calcium chloride is 6.0% of the xanthan gum quality, and the consumption of sodium tetraborate is xanthan gum 1ppm of mass, stir evenly. While stirring, add ethanol with 4.5 times the volume of xanthan gum dissolved in water, and stir evenly so that the ethanol concentration in the solution is 78%. After adding ethanol, continue stirring for 30 minutes to precipitate filaments.

[0072] 3. separate

[0073] The precipitated filaments are dehydrated and separated with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com