Method for treating alkali high-concentration organic waste water by using Fenton process

A technology of organic waste water and high concentration, applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

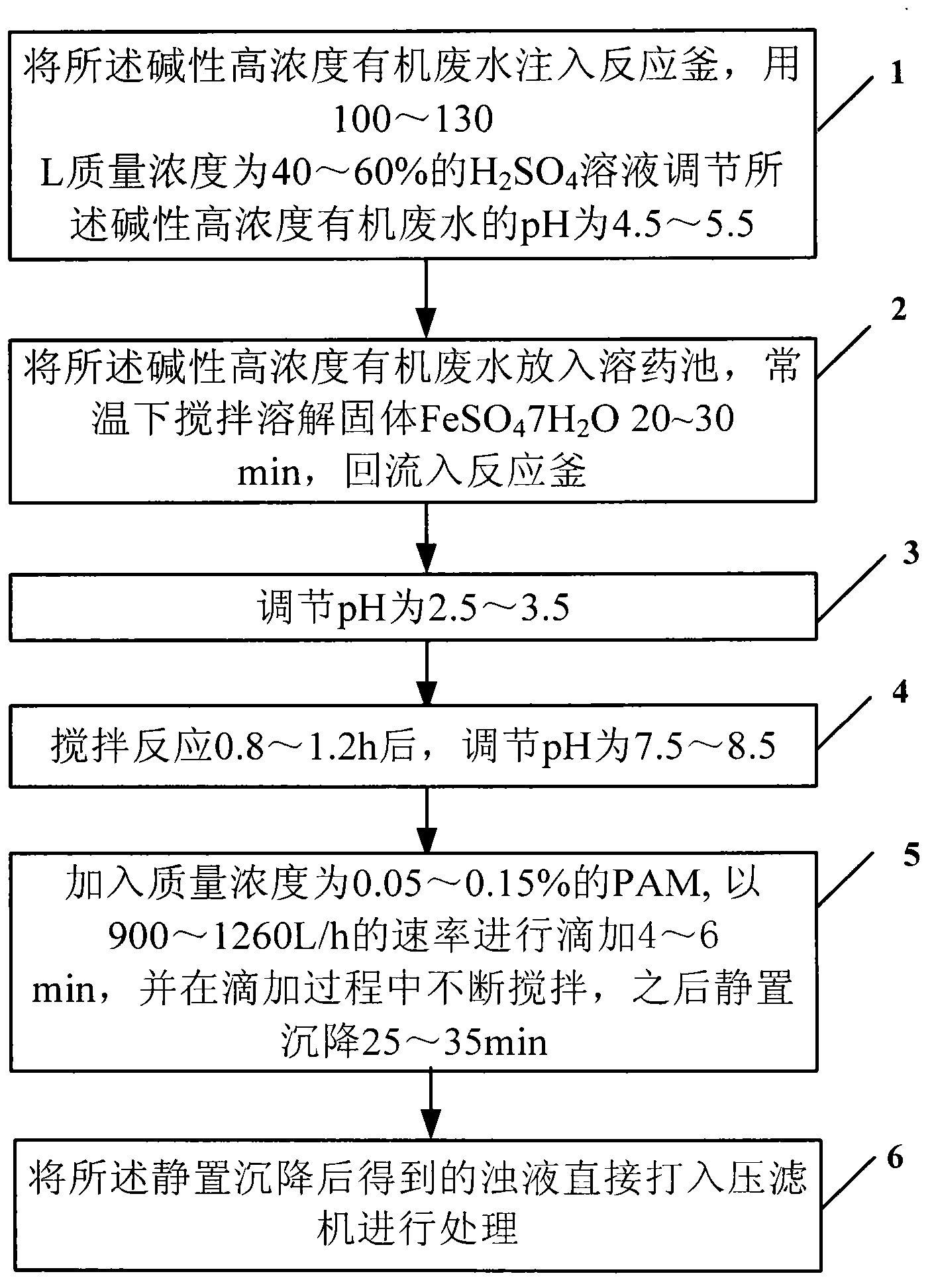

Image

Examples

Embodiment 1

[0031] A method for treating alkaline high-concentration organic wastewater by a Fenton process, comprising the following steps:

[0032] 1) The alkaline high-concentration organic waste water is injected into the reactor, and the 100L mass concentration is 40% H 2 SO 4 The solution adjusts the pH of the alkaline high-concentration organic wastewater to be 4.5;

[0033] 2) Put the alkaline high-concentration organic waste water into the medicine-dissolving tank, stir and dissolve the solid FeSO at 25°C 4 ·7H 2 O20min, backflow into the reactor;

[0034] 3) Adjust pH to 2.5;

[0035] 4) After stirring the reaction for 0.8h, adjust the pH to 7.5;

[0036] 5) Add PAM with a mass concentration of 0.05%, dropwise for 4min at a rate of 900L / h, and continuously stir during the dropwise addition, and then stand for settling for 25min;

[0037] 6) The turbid liquid obtained after standing and settling is directly injected into a filter press for processing.

[0038] As a preferr...

Embodiment 2

[0042] A method for treating alkaline high-concentration organic wastewater by a Fenton process, comprising the following steps:

[0043] 1) The alkaline high-concentration organic waste water is injected into the reactor, and the 115L mass concentration is 50% H 2 SO 4 The pH of the solution adjusting the alkaline high-concentration organic waste water is 5;

[0044] 2) Put the alkaline high-concentration organic waste water into the medicine-dissolving tank, stir and dissolve the solid FeSO at 30°C 4 ·7H 2 O25min, backflow into the reactor;

[0045] 3) adjust pH to be 3;

[0046] 4) After stirring the reaction for 1h, adjust the pH to 8;

[0047] 5) Add PAM with a mass concentration of 0.1%, dropwise for 5min at a rate of 1080L / h, and continuously stir during the dropwise addition, and then stand for settling for 30min;

[0048] 6) The turbid liquid obtained after standing and settling is directly injected into a filter press for processing.

[0049] Described adjusti...

Embodiment 3

[0053] A method for treating alkaline high-concentration organic wastewater by a Fenton process, comprising the following steps:

[0054] 1) The alkaline high-concentration organic waste water is injected into the reactor, and 130L mass concentration is 60% H 2 SO 4 The solution adjusts the pH of the alkaline high-concentration organic wastewater to be 5.5;

[0055] 2) Put the alkaline high-concentration organic waste water into the medicine-dissolving tank, stir and dissolve the solid FeSO at 35°C 4 ·7H 2 O30min, backflow into the reactor;

[0056] 3) Adjust pH to 3.5;

[0057] 4) After stirring the reaction for 1.2h, adjust the pH to 8.5;

[0058] 5) PAM with a mass concentration of 0.15% was added, dripped at a rate of 1260 L / h for 6 min, and kept stirring during the dripping process, and then allowed to settle for 35 min;

[0059] 6) The turbid liquid obtained after standing and settling is directly injected into a filter press for processing.

[0060] Described adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com